Structural Steel Decking and Other Composite Slab Systems

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

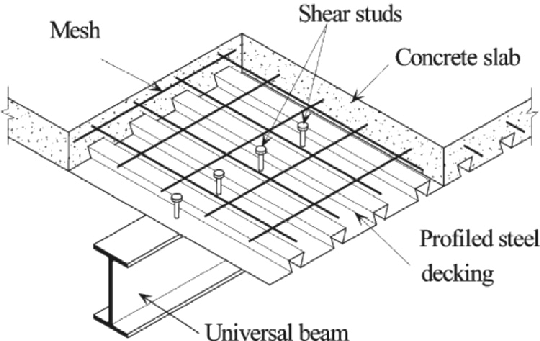

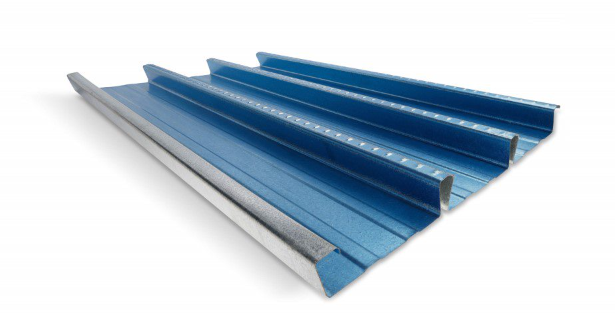

Composite slabs comprise reinforced concrete cast on top of profiled steel decking (i.e. Bondek, Condek, etc), which acts as formwork during construction and external reinforcement at the final stage.

Planning

Refer to Section: Formwork

Additional considerations must be given to the following:

- The method and location of landing the sheets and access/egress to and from the deck

- Premeasuring sheets to reduce cutting on site

- Location of temporary services and power demands for welding

- Back propping for intended loads people, equipment etc.

- Low glare structural steel decking to reduce UV radiation exposure.

- Ventilation

Design

E Structural steel decking systems must be designed and certified by a Qualified Person (structural engineer).

E Structural steel decking design documentation must:

- Be project specific

- Be signed by a Qualified Person (structural engineer) or accompanied by a certification letter that lists the drawing and revision numbers

E Design documentation should include but not be limited to:

- Proprietary fittings or systems proposed to be used

- Plans, elevations and sections to show the general arrangement of the structural steel decking and to identify and locate all components

- Concrete placement sequence

- Structural steel decking types and overlaps as per manufacturers specification

- The beams and intermediate support type, the dimensions and spacing

- The prop sizes, type, location, bracing, fixings and maximum extensions

- The methods for tying the structure to the structural steel decking

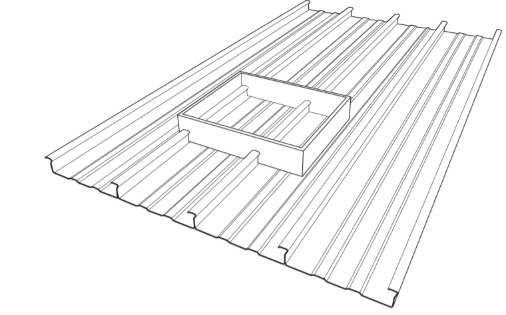

- Locations of voids and services conduits must be approved by a Qualified Person (structural engineer). Ribs should not be cut unless prior approval is given by the approved by Qualified Person (structural engineer)

E Any change to the structural integrity of the steel decking design including penetrations must be authorised by a Qualified Person (engineer).

Operational

During the construction of floors the area must be isolated and entry restricted to only those directly associated with the work process.

Where working at height is anticipated or encountered, the work must be in accordance with

- Section: Work at Heights

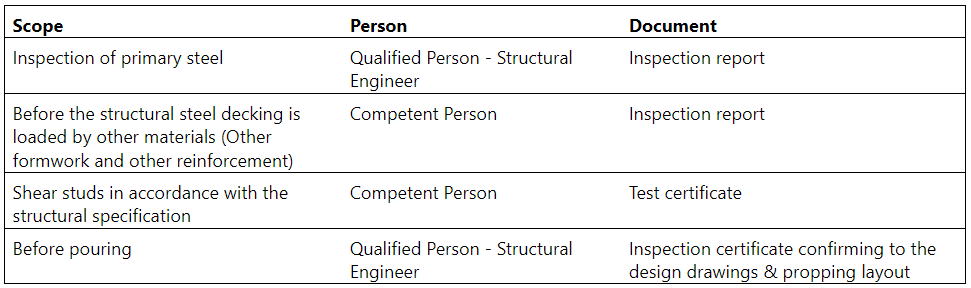

R Structural steel decking must be fixed in place in accordance with the manufacturer’s instructions, Structural steel decking must be inspected in accordance with Table 1

TABLE 1: STRUCTURAL STEEL DECKING INSPECTIONS

Raised structural steel decking protruding into beams or similar, over 150mm high, must have physical protection on the edge (i.e. metal or plastic angle).

When landing materials on the deck use timber gluts to avoid denting and bending the ribs (as damage may reduce the structural capacity).

Workers, who undertake stud welding should be trained.

Document Control

- Version 1 August 2019 – New Standard