Mobile Plant

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

Mobile plant is defined as " any plant that is provided with some form of self-propulsion that is ordinarily under the direct control of an operator", and incudes:

- Earthmoving machinery such as rollers, graders, scrapers and bobcats

- Excavators

- Cranes

- Hoists

- Elevating work platforms

- Concrete placement booms

- Reach stackers and forklifts

Hazards

Potential hazards include, but are not limited to:

- Collision with other plant or structures

- Collision with people

- Contact with in-ground / overhead services

- Excavations, pits, soak wells, tanks

- Fire

- Spills

- Public

Planning

R All mobile plant as outlined above must be inspected and applicable checklist completed prior to using the plant on site.

R The mobile plant details, inspection record, plant risk assessment and applicable maintenance records must be submitted to MPX prior to use on site and recorded on the project plant register.

- SWMS/safe operating procedure must reference the plant specific risk assessment. The mobile plant operator / person responsible for the mobile plant must implement the documented controls and sign the plant risk assessment and SWMS.

- Plant will be issued with a plant registration sticker once the inspection and checklist is completed. This must be displayed at all times in a visible location on the plant.

Prior to commencing any work activities that have the potential to impact underground services, subcontractors must consult with MPX and review site plans/as built drawings and included in the SWMS, refer section:

- Section: Excavation

- Section: Site Services

S Mobile plant may only be operated on site with MPX authorisation. Work areas must be assessed for risks, and SWMS developed and reviewed prior to using mobile plant on site.

Mobile plant must be operated in accordance with the manufacturer’s instructions, plant risk assessment, site specific requirements, SWMS and site traffic control plan / vehicle movement plan where developed.

R People operating mobile plant must be inducted into applicable SWMS and hold valid records of competency / training, evidence must be retained on site, refer to:

Operational

R Pre-start inspections must be conducted and recorded by the operator prior to operating all mobile plant.

R All mobile plant must be maintained in accordance with the manufacture’s recommendations and a process established for the ongoing maintenance after it first arrives on site.

Site-specific speed limits must be complied with at all times.

Seat belts must be worn where fitted.

Mobile plant must only be refuelled in designated areas.

Fuels must be used, handled, stored and if required disposed of in accordance with the manufactures specifications, site requirements and Section: Substances and Dangerous Goods and plant equipment general

Mobile plant must only be operated outside the ‘NO GO ZONE’ of overhead power lines, refer to:

Mobile plant must only be operated a safe distance from the edge of excavations, refer to:

- Section: Excavation.

Spotters must be used where necessary e.g. adjacent to services, structures, public.

Damaged/inoperable or unsafe mobile plant must be deemed out of service, faults etc. must be reported to the relevant MPX or subcontractor supervisor and the equipment isolated / tagged out and not be used until repaired, refer to:

Persons working in and around mobile plant must wear reflective or high visibility clothing.

Mobile plant must only be approached when stationary and the operator has signalled that it is safe to approach.

Mobile plant must not be left unattended while in use or keys left in the ignition.

Attachments (if fitted) must be lowered when machine is unattended/not in use.

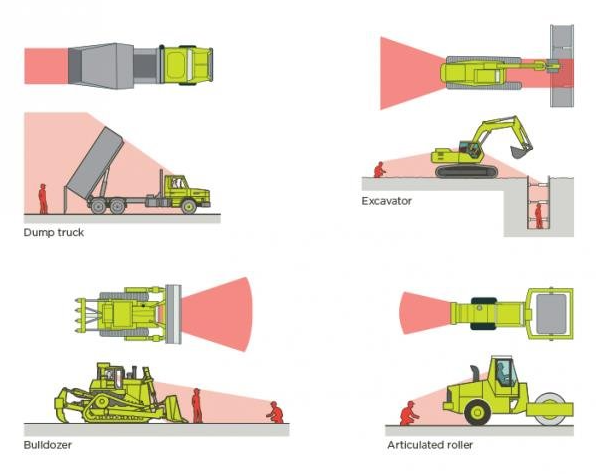

Operators and other workers should be made familiar familiar with the blind spots of particular items of plant being used. Refer diagram below.

Equipment Requirements

R Log book and manufacturers operational instruction manual must be with the equipment.

Flashing /rotating beacon, reversing alarms, horns and seat belts must be fitted and serviceable.

Guards must be securely fitted to moving/rotating parts.

Where required by the relevant standard or manufacturers requirements, roll-over protection (ROPS) must be fitted.

Where there is risk of falling objects from the operation of the plant (e.g. demolition), falling object protection (FOPS) is to be fitted. Level I (Impact strength from small falling objects eg. Bricks, small concrete blocks, hand tools) or Level II (Impact strength for protection from heavy falling objects eg rocks)

The operators cab must have means of safe access.

Where required, fire extinguisher or fire suppression system must be charged and serviceable.

Controls and gauges must be clearly marked and operational.

Emergency stop/shutdown control must be marked and operational.

Cab must be kept clean, windows clean and mirrors properly adjusted, cracked windows must be replaced.

Where structural demolition increases the risk of falling objects, machine cabs should be fitted with shatter-proof glass/protective cage and the item of mobile plant fitted with roll-over protective structures (ROPS) and falling object protective structures (FOPS) – Level II impact protection.

Light vehicles used on site refer to:

- Section: Traffic Management.

Document Control

Version 2 December 2020

- Clarification relating to SWMS/safe operating procedure referencing the plant specific risk assessment

- Inclusion of plant maintenance requirements

Version 3 9th May 2022 - Inclusion of level I and level II for FOPS