Chain of Responsibility (CoR)

Informative

Chain of Responsibility (CoR) is a policy used in Australian transport legislation to place legal obligations on all parties in the transport supply chain.

The intent of the CoR for a Vehicle is to ensure all stakeholders in the supply chain actively have in place processes that prevent breaches of the Law. These processes will ensure potential risks are considered and managed satisfactory to avoid incidents during the transporting of plant and material to and from MPX projects.

CoR legislation, applies to all parties who influence, direct or control transport operations in the supply chain – even if they have no direct role in driving / operating a Vehicle.

Multiplex engages subcontractors/suppliers to deliver, load and unload materials and equipment using Vehicles.

Definitions

- Gross Vehicle Mass (GVM) - Of a vehicle, means the maximum loaded mass of the vehicle

- Vehicle - NSW, QLD, VIC, SA, TAS, ACT - Fatigue-regulated heavy vehicle - A vehicle with a gross vehicle mass (GVM) of more than 12t; or a combination with a GVM of more than 12t Truck, or combination including a truck with a GVM of more than 12t with a machine or implement attached e.g. a truck with a crane or drill rig. All jurisdictions / states - Heavy vehicles – meaning a that has a gross vehicle mass (GVM) or aggregate trailer mass (ATM) of more than 4.5 tonnes WA - Light vehicles (e.g. cars, vans, utes) meaning a vehicle a vehicle that has a gross vehicle mass (GVM) or aggregate trailer mass (ATM) of less than 4.5 tonnes.

- HVNL - Heavy Vehicle National Law, applicable to TAS, SA, NSW, VIC QLD, (but not WA or NT) and includes but is not limited to Heavy Vehicle (General) Regulations Heavy Vehicle Fatigue Management, Heavy Vehicle (mass, dimensions and loading) and Heavy Vehicle Standards. The Road Traffic Act (Vehicles) 2014 applies to WA. Traffic Act 1987 and Traffic regulations 1999 applies to NT

- WAHVA - Western Australian Heavy Vehicle Accreditation. Accreditation in WA is mandatory for anyone that: Operates B-Double or Road Train Configurations; or Operates Truck & Trailer combinations over 42.5 tonnes gross mass; or Requires more than four single trips (oversize or over-mass) per calendar year; or Operates under concessional loading scheme; or Requires an annual Permit or Notice; or Operates a RAV exceeding a width of 2.5 metres; or Operates a RAV exceeding a height of 4.3 metres; or Operates a RAV exceeding a length of 19 metres; and Operators who perform, transport tasks for hire or reward. Restricted Access Vehicle (RAV) to which a permit applies

- Parties in the Supply Chain - Any person with an influence and/or control in the transport chain is a ‘party’ and includes, but is not limited to:

- Consignee (Receiver) - a person who receives goods from a consignor

- Packer - a person who packs goods into packages, containers, pallets to be loaded onto a vehicle for transport

- Scheduler - a person who arranges transport and assigns driving jobs and instructions to drivers

- Driver – a person who operates a vehicle to transport loads by road

- Loading/Unloading Manager - a person who supervises facilities where loading/ unloading takes place

- Loader- a person who loads goods onto a vehicle

- Unloader - a person who unloads goods from a vehicle

- Employer – a person who employs a driver of a vehicle or others in the supply chain e.g loader/unloader

- Prime Contractor - a person responsible for engaging a driver of a vehicle by a contract

- Executive - a person who is a director for, or a person concerned with, the management of a corporation responsible for controlling or directing the use of a vehicle

- Operator – a person who controls or directs the use of a vehicle

Planning

MPX in consultation with Subcontractors / Suppliers are required to identify, assess and manage work health and safety risks in supply chain operations and verify compliance with CoR requirements during project planning through risk workshops, meetings, etc. This includes the consideration of but is not limited to:

- Reviewing the specification of materials or designs that could introduce supply chain risks, heavy loads and / or dimension restrictions.

- Provision of manufactured, pre-cast or modular systems that are designed and/or specified for safe loading and unloading.

Other risks relating to CoR should be considered and assessed against existing controls to determine what, if any, additional controls are required to reduce the risk to a level that is as low as reasonably practicable (ALARP).

Refer Section: Risk Management

Subcontractor / Supplier Documentation

R Subcontractors / Suppliers documentation should be reviewed where applicable to confirm that their transport Service Providers have procedures to comply with the applicable legislative requirements.

The process should include either of the following:

R Obtaining records that the Subcontractors and/or Suppliers have applicable accreditation under the following modules

- Mass Management

- Maintenance Management

- NSW, QLD, VIC, SA, TAS, ACT- Basic Fatigue Management

- NSW, QLD, VIC, SA, TAS, ACT - Advanced Fatigue Management

- WA - Fatigue Management

R Obtaining information from the Subcontractors and/or Suppliers on how the following are managed:

- NSW, QLD, VIC, SA, TAS, ACT - Speed

- Fatigue

- Mass, dimension and loading, load restraint requirements

- Vehicle standards requirements, maintenance and repairs

Where Subcontractors/Suppliers are not accredited, their management system should be audited periodically to confirm compliance.

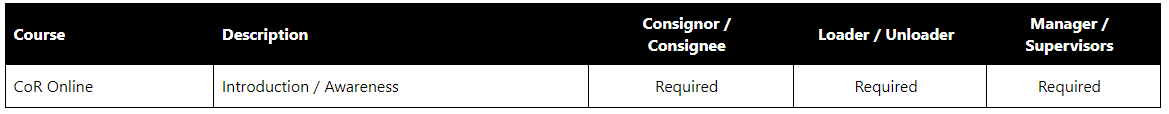

Training and Competency

MPX Directors, Managers, Supervisors and Workers must be trained in their responsibilities under applicable legislation. Refer to: Training and Competency Schedule.

Mass, Dimension & Loading Compliance

Hazards and Risks

Potential hazards and risks include, but are not limited to:

- Collision with people, other plant or structures

- Transport companies who do not have procedures in place for unloading and loading activities

- Inappropriate / insufficient loading and load restraint equipment

- Loads that exceed legal weight or dimension limits

- Hazardous and Dangerous goods

Planning

During project planning activities (e.g. risk workshops, meetings) that will occur on the project, the Project team should:

- Consider how the loads (i.e. materials and/ or equipment) are going to be loaded and unloaded including sequence, the use and availability of any specialist equipment required for lifting the load(s), suitable to the size, weight and type or any requirements for pre-slung loads.

- Develop a designated loading bay that considers the entry and exit of vehicles, safe loading and unloading of plant and materials without risk to public, personnel, traffic or adjoining buildings/structures.

- Preparing, loading, unloading and laydown/storage areas to verify they suit:

- The nature of the loads (size, weight, content)

- The types of delivery Vehicles

- Location of cranes or other means of mechanical loading/unloading

- General public interaction and traffic/road conditions

- Environment (overhead obstructions and underground services)

- Consideration of others who may be affected by the activity and layout of access routes

- Assessing the requirement for exclusions zones, barricades and signage. Refer section Barricading and Signage

Scheduling

Schedules and other plans for incoming Vehicles must as far as is practicable minimise unloading (waiting) times and incorporate plans for delays.

Communication

R Layout of access routes and other aspects of the Traffic Management Plan (TMP) / Vehicle Movement Plan (VMP)/Traffic Guidance Schemes (TGS) including revisions should be communicated to subcontractors/suppliers. Refer Section: Traffic Management

Deliveries - Generally

- Deliveries are to be scheduled as early as possible to enable safe coordination given to site constraints and conditions.

- Deliveries shall only be made to pre-arranged unloading / laydown areas

- Unless otherwise arranged subcontractors are responsible for obtaining approval and liaison with the relevant authorities for matters related to – mass, dimension and loading compliance, temporary road closures / diversions, pilot /escort Vehicles (where required) and transport permits

- Subcontractors are responsible for coordination of deliveries with MPX and supervising their deliveries and delivery Drivers

- Delivery Vehicles/Drivers shall report to the nominated gate for directions and instructions

- Delivery Vehicles as far is as practical are not to be left unattended

- Delivery Vehicles / trailers are not permitted to be left on unless approved by MPX.

Loading and Unloading

- Any identified breaches during loading and unloading must be reported to MPX Site Management who are required to report this to the Subcontractor or Consignor, including:

- Loads exceeding Vehicle load mass or dimension limits (unless covered by a permit)

- Poorly restrained loads / unsafe load restraint equipment

- Vehicle Drivers who appear to be unfit for work.

- Where this has been identified, MPX:

- May refuse to unload the vehicle

- Require the Subcontractor/Consignor to take necessary measures to rectify / re-load the load

- Delivery Vehicles shall be stationery and engines should be switched off (where practical) whilst unloading

- Unloading shall only be carried out by appropriately inducted / trained / licensed people

- Loads are to be unloaded within the confines of the designated loading bay for the project

- As far as is practicable, loads are not to be lifted, suspended above or travel over people.

- Hoardings protecting the general public are to be installed. Refer Section Hoardings

Load Mass and Dimensions

Loaders/Loading Managers should obtain information from Drivers to identify the following prior to loading:

- Gross vehicle mass of the Vehicle

- Dimension limits

Loaders / Loadings Manager should consult with Drivers to:

- Keep a ‘running total’ of the load mass, or

- Where fitted use of the On-Board Monitoring (OBM) systems to calculate the gross vehicle mass of the Vehicle

Load Stability

Drivers in consultation with Loaders must:

- Position loads such that there is 'load share' on axles, maintaining adequate stability, steering and braking.

- Where supplied, use of loading plans/diagrams to verify that loads are not placed in a manner that makes a Vehicle unstable.

Load Restraint

Drivers of Vehicles are responsible for:

- Securing loads (using rated equipment) so they are unlikely to fall or dislodge during transport and / or unloading activities. Loads must be checked by the Driver before transportation to verify they are secure.

- Checking load restraint methods comply with legislative requirements and where available, any load restraint guide. (I.e. Load Restraint Guide 2018 / Load Restraint Guide for Light Vehicles 2018 / Load Restraint Guide Second edition 2004)

- Where practicable, use covers to prevent material leaving the Vehicle during load and haul operations.

Precast concrete elements/ structural steel

Unloading / loading of precast concrete elements / structural steel must be undertaken in accordance with

- Section: Precast Concrete Elements

- Section: Structural Steel

Sea Containers

- The person using the sea container (MPX or the Subcontractor) shall be present during the delivery, unloading loading and removal of the sea container.

- The contents of any sea container must be inspected prior to being winched or lifted.

- The Driver must be informed of the total weight of the sea containers and its contents before being winched or lifted.

- R Container weight declarations must be provided

- The rated capacity of the truck, winch and any associated lifting equipment shall be verified prior to movement.

- The truck and sea container shall be aligned prior to winching.

- Exclusion zones shall be established prior to winching or lifting

Speed Compliance (NSW, QLD, VIC, SA, TAS, ACT)

Hazards and Risks

Potential risks include, but are not limited to:

- Over-scheduling a driver such that scheduled runs cannot be completed without exceeding the speed limit

- Loaders experiencing delays in loading which puts pressure on the driver to speed in order to recover lost time

Communication

The Site Manager or Supervisor should provide timely communication and advance notification to subcontractors/suppliers and other supply chain parties wherever possible when there are changes to schedules, including delays, so Drivers are not directly pressured, or feel indirectly pressured, to exceed the speed limit.

Fitness for Work

Hazards and Risks

Potential hazards and risks include, but are not limited to:

- Fatigue due to over-scheduling, insufficient rest breaks, unfavourable rosters (day / night shift)

- Loaders experiencing delays in loading which impact the Drivers’ work time

- Consignors demanding unachievable delivery times

- Transport company not providing appropriate facilities to enable Drivers to rest

- Transport company payment schemes that incentivise Drivers to skip rest breaks

Fitness for Work

- Obtain records of fatigue management systems from subcontractors / suppliers. (Refer Subcontractor / Supplier Documentation).

- If a Driver self-declares or is deemed unfit to drive, MPX should advise the Driver they are not fit to drive, notify the Subcontractor / Consignor immediately, and take care of the driver’s welfare by making alternative arrangements including provisions for the Driver to have an additional rest break.

- All Drivers of Vehicles are subject to random, for cause and post incident drug and alcohol screening. Refer: Drugs and Alcohol Management Plan

Communication

Communication with Subcontractors/Suppliers should address the following:

- Orders with Subcontractors/Suppliers must be placed as far in advance as possible

- Updates to delivery schedules

- Identification of unloading or loading requirements (i.e. plant type/size) so project resources can be planned and prioritised to avoid unnecessary delays

NSW, QLD, VIC, SA, TAS, ACT - Communication with incoming heavy Vehicle Drivers must include that:

- Drivers of fatigue-regulated heavy Vehicles are aware of the location of rest facilities and amenities, to assist with managing fatigue

Legal Requirements

Document Control

Version 01 - September 2021