Roof Safety Mesh

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Operational

E Safety mesh must comprise of 2 mm diameter wire of not less than 450 mega Pascals tensile strength welded in to a mesh configuration, with longitudinal spacing’s of 150 mm and crosswire spacing of 300 mm.

E The roofing subcontractor is responsible for the supply and installation of the safety mesh and must verify compliance with AS/NZS: Safety Mesh 4389.

E A test certificate issued by NATA registers, or equivalent, testing authority showing that a sample of mesh has successfully undergone test as described in AS/NZS: Safety Mesh 4389 must be produced by the roofing subcontractor and a record to maintain on site.

Safety mesh should be where ever practicable fixed to metal purlins through a hole drilled through the top of the purlin and tied off with at least 4 full turns.

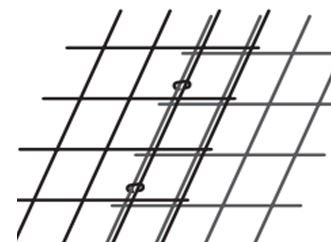

The runs of mesh must be side lapped by at least 150 mm.

If the purlin spacing exceeds 1.5 metres, the runs of mesh must be side lapped at least 300 mm.

Lapped mesh must be fixed with 2 mm staples between each purlin:

- Staples must be installed from below

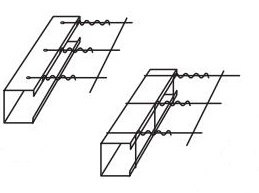

Where possible joining mesh transversely should be avoided, where unavoidable:

- The knot and tie should be the full length of the tail wire, which should be a least 300 mm in length

- The first tail wire should be tied at least 3 times around the knot

- The other tail wire is placed under the longitudinal wire and tied around the transverse wire.

R Verification (i.e. a handover certificate) must be issued by a Competent Person (installer) for the installation and inspection of roof safety mesh.

Legal and Other Requirements

- AS/NZS: Safety Mesh 4389

- NSW Code of practice ‘Safe Work on Roofs part 1 Commercial Buildings.

- Managing the risk of falls at workplaces Code of Practice (Qld) 2018

Document Control

Version 1 August 2019 – New Standard