Penetrations in Floors

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Planning

Penetrations considerations should be given to :

- What types of construction activities are likely to occur in and around the penetration?

- Does the penetration need to be covered with plywood, steel or other suitable material?

- Does the penetration cover need to support anyone / anything?

- Will plant or machinery be driven / landed on the penetration?

- Could a person or object fall through the penetration?

- The need for edge protection?

Operational

All penetrations must be protected immediately after they are created with:

- Edge protection/handrail system or

- Covers

In the case of penetrations in floors in buildings or structures.

- Any hole or opening (other than stairwell, lift well, or vehicle inspection pit with dimensions of 200 mm x 200 mm but less than 2 metres x 2 metres, in:

- A floor (other than concrete) is covered with material that is strong enough to prevent persons or things entering or falling through and securely fixed to the floor.

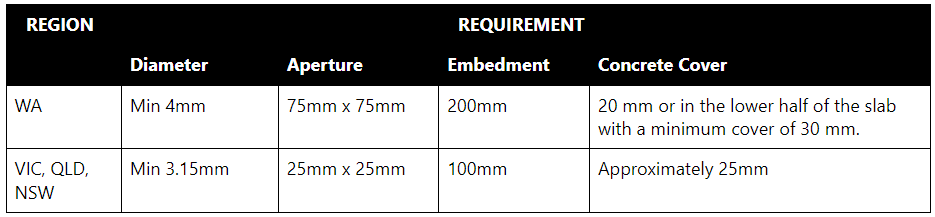

- A concrete floor has if practicable wire mesh that meets the following:

Wire mesh must not to be used as a working platform.

Wire mesh must only be removed for the installation of services.

Only the required portion of wire mesh is to be removed immediately before the installation of services.

Any cover used over a hole or opening in a floor or other trafficable structural surface (e.g. roof, pit etc.) must be:

- Marked with high visibility paint clearly with the words ‘DANGER HOLE BENEATH’ (WA) or other clear identification markings (NSW, QLD, VIC)

- Secured in place and be able to withstand the foreseeable loads imposed, or have edge protection (as defined above) installed around the penetration or have timbers/wheel stops or similar installed.

- Free of slip / trip hazards – e.g. Where timber is used edges to be splayed.

Where penetration covers or edge protection must be removed for work purposes, they should only be removed immediately prior to the work and barricading and warning signs must be in place.

R WA - Note: Where plant / equipment is located on or has the potential to travel over a penetration cover, the rated capacity shall be verified by a qualified person.

Where vertical risers have had the wire mesh removed and service installed – the riser shall be protected by:

- Edge protection installed; and either

- A cover as defined in “Operational” section above; or

- Where practicable to do so, duct work installed to a minimum of 900mm above the finished floor level

Legal and Other Requirements

- Work / Occupational Safety & Health / Regulations

- Formwork Code of Practice (QLD) 2016

Document Control

Version 1 August 2019 – New Procedure

Version 2 9th May 2022 - Inclusion of the requirements for vertical risers which have had the wire mesh removed and service installed