Respirable Crystalline Silica (RCS)

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

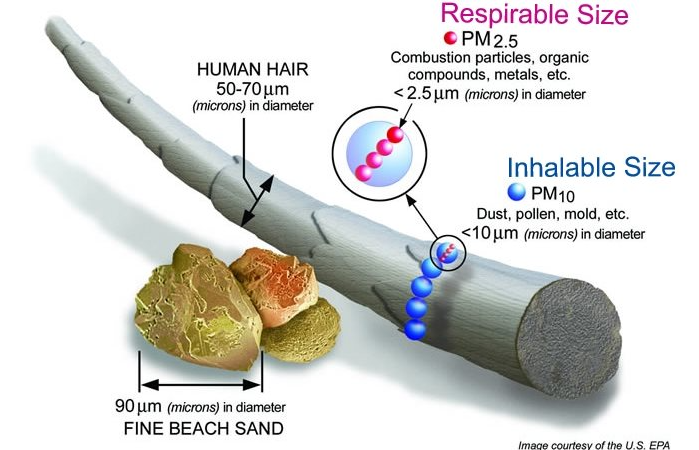

Crystalline Silica is one of the most abundant minerals in the earth and is a basic component of soil, sand, granite and many other minerals.

There are three main forms of crystalline silica,

- Quartz (Most common)

- Cristobalite

- Tridymite.

Respirable crystalline silica (RCS) is created when cutting, sawing, grinding, drilling, and crushing stone, rock, concrete, brick, block, and mortar. Activities such as abrasive blasting with sand; sawing brick or concrete; sanding or drilling into concrete walls; grinding mortar; manufacturing brick, concrete blocks, stone benchtops, or ceramic products; and cutting or crushing stone result in worker exposures to respirable crystalline silica dust.

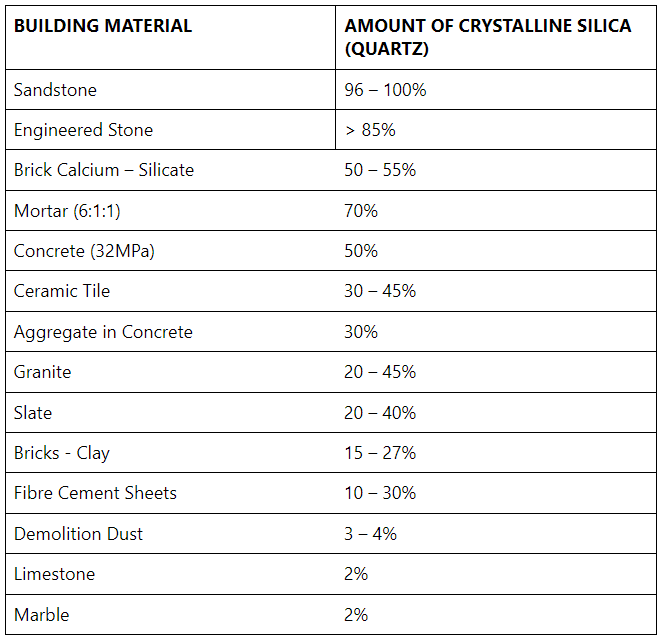

Typical concentrations of crystalline silica found in building materials are outlined in the table below.

TABLE 1: TYPICAL CONCENTRATIONS OF CRYSTALLINE SILICA IN BUILDING MATERIALS (SOURCE: WORKSAFE QLD)

Health Risks

Potential health risks include, but are not limited to:

- Silicosis (chronic, accelerated, acute)

- Chronic obstructive pulmonary disease – COPD (chronic bronchitis, emphysema)

- Renal disease

- Sceloderma

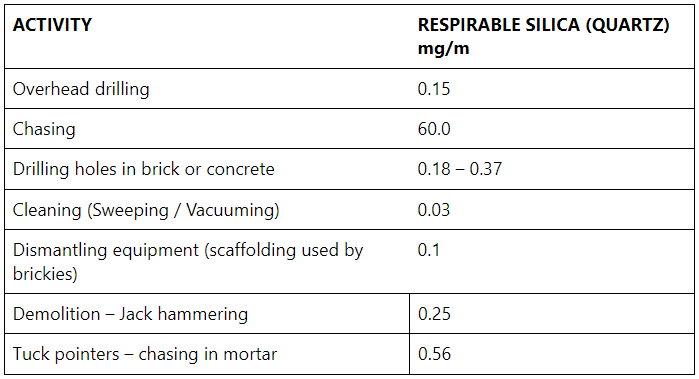

Example concentration levels of RCS dust of construction activities, without controls are provided in the table below.

TABLE 2: DATA COLLECT BY RESEARCHERS IN WA AND IN THE NETHERLANDS IN TYPICAL CONSTRUCTION JOBS

Exposure Limits

- The exposure limits for RCS is 0.05 mg / m3 over eight (8) hours (time-weighted average) - NSW, NT, QLD, VIC, SA, WA, ACT and Commonwealth.

Design and Planning

During the project design and planning stages, the project team should endeavour to identify opportunities, where practicable, to eliminate materials containing crystalline silica, giving consideration to the availability of alternative materials with no silica and the project brief.

Where total elimination is not practically achievable the project team should, as far as is practicable endeavour to identify and use:

- Alternative materials with low crystalline silica content

- Materials / substances that can be procured precut or preprepared

- Controls as listed under operational below.

Reference to the management of RCS should be included in:

- Subcontract agreements

- Risk workshops

- Subcontractor SWMS

Considerations should be given to the following when planning and developing controls

- Identifying tasks that are likely to create RCS

- crystalline silica content in the materials by reviewing manufacturers Safety Data Sheets (SDS) or information from the manufacturer

- Reviewing other sources of information (i.e. manufacturers data, air monitoring results, other industry guidance) to identify if there is likely to be a RCS hazard

- Determining the total amount of exposure time per shift for a worker (time weighted average) by referring to previous tests

- Separating activities that have the potential to generate RCS

- Establishing a cutting room dedicated to the cutting of materials with high silica content where there is potential for the generation of RCS

R QLD - A Dust Control Plan must be supplied to MPX by engineered benchtop installers

R QLD - An audit of the factory supplying the engineered benchtops should be conducted by MPX prior to supply of benchtops.

Training

All employees and the workforce must be informed of the risks associated with exposure to RCS and typical control measures to protect workers via general safety induction / project induction and other awareness programs.

Operational

Dry cutting / drilling / grinding without controls of any engineered stone on a MPX site is prohibited, unless the tool:

- Has an integrated water delivery system that supplies a continuous feed of water (on-tool suppression), or

- Is fitted with on-tool extraction attached to a HEPA filtered dust class H vacuum cleaners (or similar system that captures the dust generated)

Where RCS dust has the potential to be generated, controls include but are not limited to:

- Wetting or dampening down surface areas

- Using water sprays during earthworks and demolition etc.

- Using mobile plant with enclosed cabs and M class filters

- Using wet sweepers / vacuums (with ‘H’ or ‘M’ class filters) to clean up (where practicable)

- Collection and containment of dust in suitable containers/bags prior to disposal

On-tool dust suppression/extraction systems are required to be used and maintained where the work involves cutting, drilling or grinding materials containing crystalline silica, these include but are not limited to:

- Wet cutting/ water injection systems

- Local extraction systems (fixed or on-tool)

- Dust hoods attached to vacuum cleaner

- Shadow vacuuming.

- Users of such equipment should note that maintenance of equipment is vital in order to sustain the equipment’s effectiveness in limiting release of RCS dust.

- Installing vacuum attachments on tools and shadow vacuuming to capture dust

- Local extraction systems (fixed or on-tool)

- Dust hoods attached to vacuum cleaner.

Where Respiratory protection equipment (RPE) is required to be worn, it must be fit tested and checked, maintained and disposed of in accordance with manufacturer’s specifications. And used in conjunction with other controls.

The use of RPE should be used in conjunction with other controls (where elimination is not practically)

Where on-tool dust suppression / extraction systems or water suppression cannot be practically implemented, work areas should be isolated and access restricted to those involved in the process (e.g. via barricades and signage etc.). Control measures such as enclosures, ventilation and RPE should be implemented.

Use of compressed air / blowers should be limited and controlled when being used to blow down/clean off surfaces.

In cases where work areas have poor air-flow / ventilation (i.e. work in restricted spaces and confined spaces), consideration should be given to introduction of mechanical extraction ventilation to remove contaminated air from the workplace or from a work area.

Where MPX observes that the controls for the management of RCS are deficient, the work must cease until effective controls are implemented.

QLD - Cutting, grinding, trimming or polishing of engineered benchtops should be conducted offsite. Where this cannot be undertaken offsite, then the work must be completed in an isolated cutting room with:

- Adequate ventilation and signage

- Water suppression or local exhaust ventilation (LEV) controls on cutting/grinding equipment

- RPE (min P2) being worn and fit tested on persons

- Cleaning performed with a H class vacuum

Health Surveillance

Health surveillance must be provided to workers:

- In accordance with applicable regulations

- Who are carrying out ongoing work using, handling, generating or storing RCS and there is a significant risk to the worker's health because of exposure

- When relying on personal protective equipment (PPE) such as respirators for controlling their exposure below the exposure standard levels

Document Control

Version 1 August 2019 – New Standard

Version 2 January 2020 - Additional QLD requirements relating to benchtops added incl. dust control plan, factory audit and cutting room.

Version 3 October 2020 - Workplace Exposure Standard (WES) updated