Pressure Testing Pipe Work

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

This section describes MPX approach to hydrostatic and pneumatic pressure testing for building services (hydraulic, fire, mechanical, gas/fuel) pipework and associated systems during installation and commissioning, and highlights potential hazards and risks related to stored energy associated with pneumatic testing. There are many other applications not specifically addressed in this section; however all use pipe work materials as described. MPX requires contactors to review and incorporate the manufacturer’s information and installation guidelines in their safe work methodology.

Hazards

Potential hazards include but are not limited to:

- Stored energy

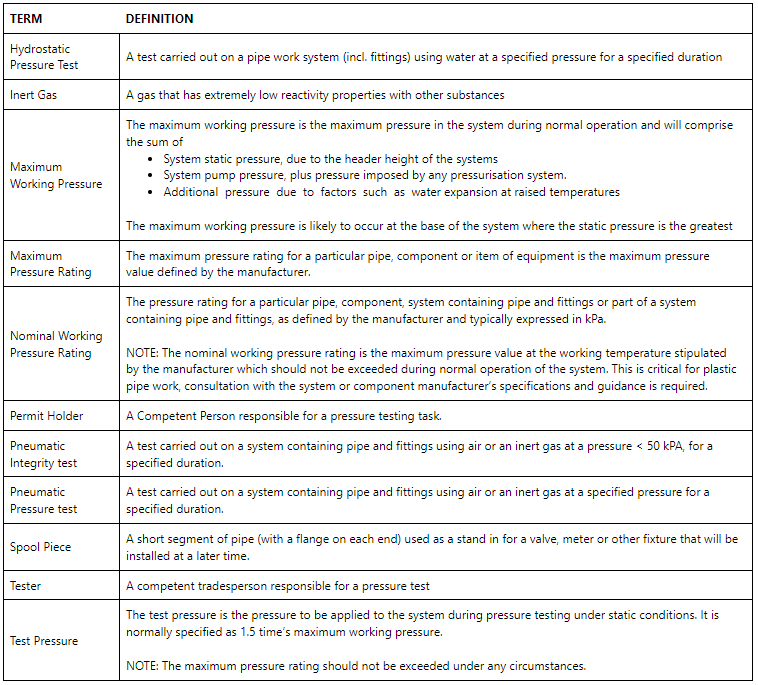

Table 1: Term and Definitions

Informative

Water Supply to Fill a Pipe Work System in Preparation for Hydrostatic Pressure Testing

A Temporary connection from the mains water supply must comply with the water authorities guidelines, for example an acceptable connection incorporates a backflow prevention device in accordance with AS 3500.

A temporary connection from fire hydrant pipe work is allowable provided that prior permission has been obtained from the jurisdictional fire authority and relevant water authority.

In some cases temporary site mains water supply used to fill pipe work systems have been known to harbour large quantities of bacteria which then contaminate filled systems. The water supply is to be sampled to establish a water quality baseline. This will enable the water treatment specialist to effectively and efficiently select the correct water treatment option required for the system.

Pressure Testing

The subcontractor must detail the safety work procedures for pressure testing. The safe work procedure must be submitted to MPX for review.

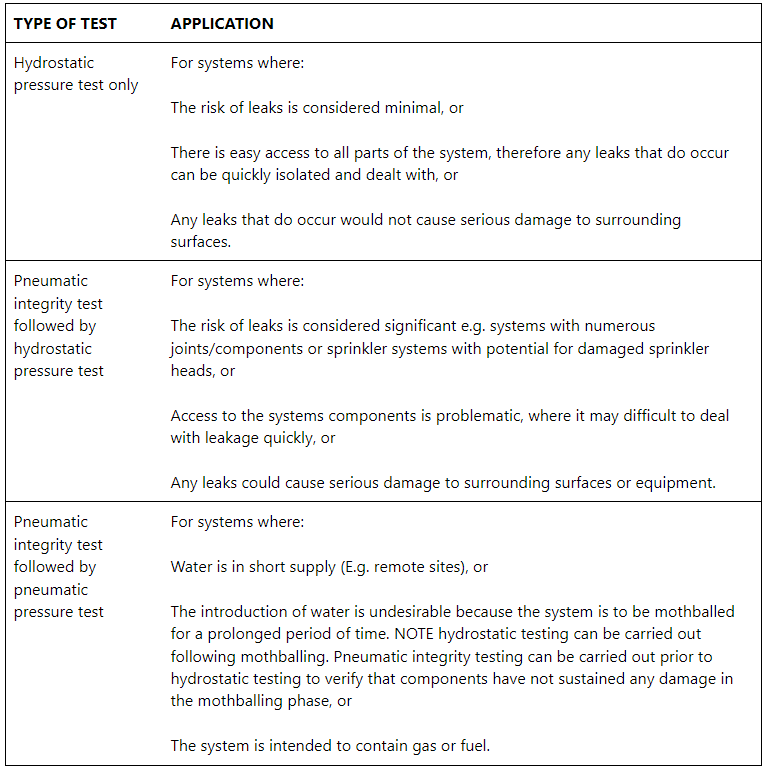

The type of pressure testing applied to a system may differ due to circumstance: 3 types of typical pressure tests adopted to test pipework systems are described in Table 2.

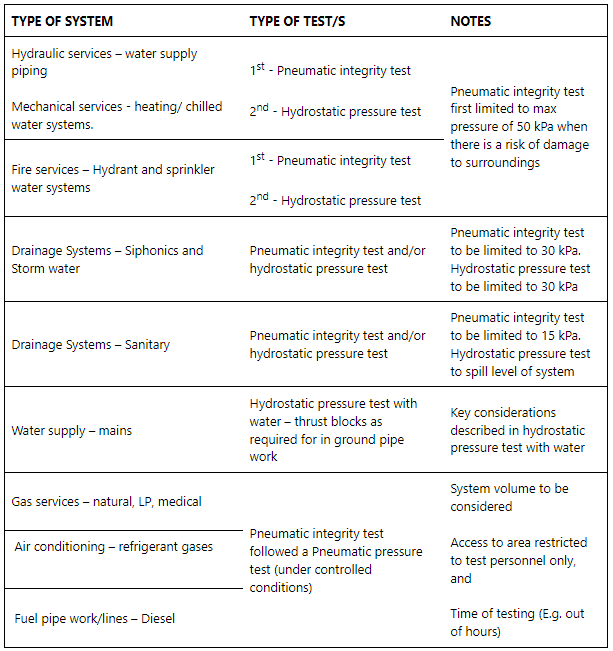

Different systems required application of either hydrostatic or pneumatic pressure testing or in some cases both, these are described in Table 3.

The test pressure is the pressure to be applied to the system during pressure testing under static conditions. It is typically specified as 1.5 time’s maximum working pressure. The systems working pressure/s and test pressure specifications are normally detailed in the applicable service design documentation.

Pressure testing must not be undertaken until the systems working and test pressures have been defined and are understood by the tester.

The maximum test pressure rating of any system component (E.g. pipework fittings, valves, connections, bellows etc.) should not be exceeded under any circumstances.

THERE IS AN INCREASED RISK ASSOCIATED WITH PNEUMATIC TESTING.

The amount of energy stored in compressed air, is approximately 200 times greater than that contained in water for the equivalent pressure and volume.

If a system component fails during a pneumatic pressure test, there is a high risk of serious injury or damage.

Pneumatic pressure testing should be avoided as far as practical.

In some cases pneumatic integrity testing at low pressures (< 50 kPa) may be considered as a useful means of detecting potential leaks before a full pressure test in conducted.

Pneumatic integrity testing on MPX projects is limited to a maximum pressure of 50 kPa.

Pneumatic pressure testing must be authorised by MPX Site/Services Manager.

Circumstances where pneumatic pressure testing is acceptable are

- When a long period of time (E.g. > 6 months) is scheduled to elapse between hydrostatic pressure testing and the systems intended operational use e.g. mothballing. In this case pneumatic testing may be preferred due to potential bacteria and corrosion issues.

- For various gas and fuel systems.

For the above examples test pressures must be defined in consultation with the system designer.

In cases where:

- Pneumatic pressure testing or

- Chemicals must be used in hydrostatic pressure testing.

The testing must be in accordance with applicable:

- Health and safety legislation

- Codes of practice

- Australian standards.

Sensitive Equipment (energy metres, commissioning sets, etc.)

Where a temporary ‘spool’ piece is installed to protect sensitive equipment, the ‘spool’ piece is to be removed when the hydrostatic pressure test or (where required) the chemical cleaning/disinfection has been completed.

Following the removal of the spool piece, sensitive equipment must be installed with compatible mating flanges / gaskets rated to the specified system working pressure and then hydrostatically pressure tested to the maximum pressure rating of the sensitive equipment in accordance with the manufacturers guidelines.

Plastic Pipes

(Poly vinyl chloride - PVC, polyethylene or cross linked polyethylene - PE, PEX & polybutylene - PB)

In systems compromising of plastic pipes there is likely to be greater expansion of pipe material when pressure or temperature are increased causing any test pressure imposed to decrease over a period of time.

Plastic pipes have specialised jointing techniques which, if faulty or poorly installed will fail.

Acceptable pressure losses must be calculated in accordance with the pipe manufactures guidelines.

Metal Pipe Work Systems

For all metal pipe work systems, a test pressure of at least 1.5 times the maximum working pressure of the system must be applied.

Type of Test and Application

Table 2: Type of Test and Application

Type of System, Test and Notes

Table 3: Type of System, Test and Notes

Hydrostatic Pressure Test

Hydrostatic pressure testing may be carried out when a defined section of a system or when the whole system is completed.

Hydrostatic testing must be only carried out when:

- The risk of leaks is considered minimal, or

- There is easy access to all parts of the system, therefore so that any leaks that do occur can be quickly isolated and dealt with, or

Where a hydrostatic pressure =>2000kPA test is planned authorisation is required to be obtained from MPX Site / Services Manager, in some cases this test maybe required to be undertaken outside of normal work hours and in WA an 'Out of hours' permit is required.

Any leaks that do occur would not cause serious damage to surrounding surfaces.

Hydrostatic pressure testing should be carried out immediately before the commencement of chemical cleaning agent or disinfection, which should be carried out immediately before system commissioning.

The hydrostatic pressure test should be completed within 48 hours to minimise the opportunity for bacteria to develop on pipe surfaces.

Where there is a delay of more than 48 hours between finishing the hydrostatic pressure test and the start of chemical cleaning or disinfection, the system should be left full of biocide dosed water. This controls bacteria levels and prevents the formation of bio film on pipe surfaces.

Hydrostatic pressure testing must be completed prior to any wall / ceiling closures or backfilling of excavation or trench.

NOTE: In some cases it may be necessary to keep sections of the system or individual components isolated and dry whilst other parts of the system are tested. This may be necessary if:

- The required hydrostatic test pressure is greater than 1.5 times the nominal pressure ratings of any system component. In this case these sections or components must be kept isolated to avoid potential damage

- The system incorporates plastic pipe which is to be left dry until the steel components of the system are chemically cleaned and treated. Keeping plastic pipes dry should avoid the need to include them in the chemical cleaning process.

Only those parts of the system that must be tested imminently should be filled. Other parts of the system must be blanked off or isolated. Isolating ball valves with reliable shut off functions should be installed for this purpose.

Prior to Filling the System

Prior to filling the system the installer must:

- Have available the manufacturers specifications / guidelines for testing

- Make arrangement for the appropriate witnessing authority to be available to verify the test

- P WA obtain authorisation from the MPX Permit Issuer by completing the relevant sections of a Pressure test permit and attaching the required documentation as defined by the permit.

- P WA, display signage and the Pressure test permit with test rig in the test location

- Inspect pipes upstream of pumps of downstream metres for debris which could cause damage, where debris is found it must be removed

- Inspect all parts of the system for completeness to confirm they are watertight

- Close all valves at the limits of the section of pipework to be tested and open all valves within the limits of the test section

- NOTE: In large systems, to facilitate monitoring, it may be necessary to keep some sections of the system isolated initially and open them in stages

- Verify that the fill pressure is sufficient to fill the system completely within a reasonable timeframe

- Verify that the proposed test pressure and the available fill water pressure are not predicted to exceed 50% (half) the specified nominal pressure ratings of any system components included within the test area unless specified otherwise and the test pressure falls below the maximum pressure rating of any system component

- Verify that there is an adequate number of air vents in the system and that they are accessible to allow the system air to be vented as the system fills

- NOTE: Automatic air vents may be left un-isolated but should be isolated after completion of the fill. Manual air vents will need to be monitored during the fill and closed on completion

- Verify that an adequate number of Competent Persons are readily available to check the system for leaks/failures as the system is filled and, that all the persons involved with the test have been briefed. The pump attendant must be nominated

- Verify that in the event of a leak:

- Clean up equipment (brooms/mops/ wet vacuums) is readily in the test area, and

- That sensitive equipment or surfaces are adequately protected.

- Verify drain cocks are accessible and have hoses run to drains so that the system can be emptied immediately

- Have connected a means of raising the system pressure to the required test pressure such that the test can take place as soon the system is filled

- R Have fitted at the lowest part of the system a certified calibrated test pressure gauge or manometer, capable of measuring pressure variations of at least 0.1 bar such that the pressure can be monitored during the test.

Filling the System

During the filling of the system, the tester must:

- Release air from high points systematically up through the system.

- Walk the system continuously checking for leaks by the noise of escaping air or signs of liquid leakage

The pump must be attended at all times whilst running

System Test

Once the system is full the system pressure test must commence without delay.

Continue to fill the system with water.

When the system is full of water, the pressure must be increased in staged intervals; the pressure must be raised at intervals in accordance with the pipe manufactures guidelines (to the test pressure and seal the system).

NOTE: Monitoring of the system for leaks should take place continuously throughout all stages of the test.

Monitor the pressure if:

a. the pressure falls the test has failed, check the system for leaks or valves passing

- the test pressure holds steady for a minimum of one (1) hour, the test is deemed to be successful

If a successful test is not achieved:

- Implement any necessary safety precautions

- Commence clean up, and

- Report the result to MPX

- MPX Permit Issuer to close the permit out.

When a successful test is achieved:

- Have the appropriate witnessing authority sign off the relevant test verification documentation.

- Report the result to MPX Permit Issuer

- MPX Permit Issuer to close the permit out.

Draining the System

Following satisfactory completion of the pressure test, the system should be left charged at a reduced pressure (site mains pressure approx. 250-400 kPa) with water and if required a biocide agent added as specified by water treatment consultant /contractor.

In the event of a full system drain down consideration should be given to the following:

- Before draining, manual air vents must be opened, particularly on cylinders or closed vessels, to prevent collapse under vacuum

- Any dirt pockets or strainers to be cleaned

- Potential corrosion issues for metal piping systems.

Where biocide dosed water has been used for testing, consideration may be given to leaving this dosed water in the system. The water treatment consultant /contractor must be consulted.

Pneumatic Integrity Test with Air / Inert Gas

Informative

A pneumatic integrity test is required prior to a hydrostatic test to verify there are no open ends or joints which are not welded or crimped prior to filling with water: this is to prevent water damage to surrounding areas.

Pneumatic integrity pressure testing is not permitted to exceed 50 kPa.

NOTE: If the air for the test is to be taken from a source with a pressure higher than 50 kPa, a pressure reducing valve must be set to open if the test pressure (e.g. ≥50 kPa) is exceeded.

During the planning stage for pneumatic integrity testing, system volume should be considered and limited under test to reduce the volume of stored energy of compressed air placed in the system.

The tester is deemed responsible for constantly monitoring the test pressure.

Prior to Testing

The subcontractor must detail the safety work procedures for pneumatic integrity testing. The safe work procedure or SWMS or JSA must be submitted to MPX for review.

Prior to filling the system the installer must:

- P WA - obtain authorisation from the MPX Permit Issuer by completing the relevant sections of a Pressure Test Permit and attaching the required documentation as defined by the permit

- Confirm a suitable compressed air source is available which, as far as practicable can be controlled from the outside the test area

- Verify that any flexible pipes in the air supply are securely restrained at each end and along their length in order to prevent “whipping” if a connection fails

- Inspect all parts of the system for completeness

- Close all valves at the limits of the test section of pipework and open all valves within the limits of the test section

- Check that all air vents are isolated (closed)

- Have a recently calibrated test pressure gauge or manometer, capable of measuring pressure variations of at least 0.1 bar such that the pressure can be monitored during the test

- NOTE: that for an air test: the gauge does not have to be located at the bottom of the system since the measurement is not influenced by the systems static pressure

- P WA - Display signage and the Pressure test permit with test rig in the test location

- Verify that an adequate number of Competent Persons are readily available to check the system for leaks/failures as the system is filled and, that all the persons involved with the test have been briefed.

System Test

The compressor must be monitored at all times to prevent over pressurisation of system.

Increase the air pressure in the system up to the maximum of 50 kPa and seal the system.

Monitor the pressure if:

- The pressure decreases over a ten (10) minute period, check the system for leaks by listening for escaping air or by using a leak detection solution.

- The test pressure holds constant for ten (10) minutes the test is deemed a successful test.

Draining the System

Once a successful test is achieved, release the air pressure in a deliberate and controlled manner.

Complete or Continue Testing

Where permit was issued for pneumatic integrity test only:

- Report the result to MPX Permit Issuer

- MPX Permit Issuer to close the permit out.

Where authorised and permitted continue with hydrostatic pressure test or pneumatic pressure test in accordance with the relevant sections in ‘Pressure testing pipework’.

Prior to Pneumatic Pressure Test

P Where pneumatic pressure test is planned at a pressure > 50 kPa, authorisation must be obtained from the MPX Services Manager & Site Manager, in some cases pneumatic pressure testing will be required to be completed out of normal work hours and in WA an Out of hours permit is required to be raised.

Access to pneumatic pressure test areas is to be

- Coordinated with MPX and

- Restricted via hard barricading and signage stating ‘Do Not Enter Pneumatic Pressure Test in Progress’ or similar.

P WA - Display the Pressure test permit with test rig in the test location.

Tester must verify that the test manifold ‘rig’ is constructed from suitable pressure rated fittings

All relief valves and regulators are isolated (where applicable).

Verify that an adequate number of Competent Persons are readily available to check the system for leaks/failures as the system is filled and, that all the persons involved with the test have been briefed.

The compressor must be attended at all times whilst running.

And in accordance with ‘Pneumatic integrity testing’.

Pneumatic Pressure Test

Only authorised test personnel are permitted within the test area.

The compressor must be attended at all times whilst running.

Monitoring of the system for leaks should take place continuously throughout all stages of the test.

Raise the pressure in staged intervals per the pipe manufactures guidelines, to the test pressure and seal the system.

Monitor the pressure, if:

- The pressure decreases, check for leaks or valves passing

Do not leave compressor unattended whilst leaks are investigated, the compressor must be monitored to prevent over pressurisation of system.

2. The test pressure remains constant for minimum one (1) hour, the test is deemed successful.

When a successful test is achieved:

- Have the appropriate witnessing authority sign off the relevant test verification documentation

- Report the result to MPX Permit Issuer

- MPX Permit Issuer to close the permit out.

Draining the System

Once a successful test is achieved and witnessed, release the air/inert gas pressure in a deliberate and controlled manner.

Document Control

Version 1 August 2019 – New Procedure

Version 2 November 2020 - Procedure applied to VIC and QLD

Version 3 July 2021 - Pneumatic integrity testing on MPX projects reduced to 50 kPa. Where a hydrostatic pressure =>2000kPA test is planned authorisation is required to be obtained from MPX Site / Services Manager.