Confined Space Entry

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Definition

A confined space is - An enclosed or partially enclosed space that is not intended or designed primarily for human occupancy, within which there is a risk of one or more of the following:

- An oxygen concentration outside the safe oxygen range

- A concentration of airborne contaminant that may cause impairment, loss of consciousness or asphyxiation

- A concentration of flammable airborne contaminant that may cause injury from fire or explosion

- Engulfment in a stored free flowing solid or rising level of liquid that may cause suffocation or drowning

Examples

Storage tanks, boilers, pipes, sewers, shafts, ducts, process vessels, tunnels

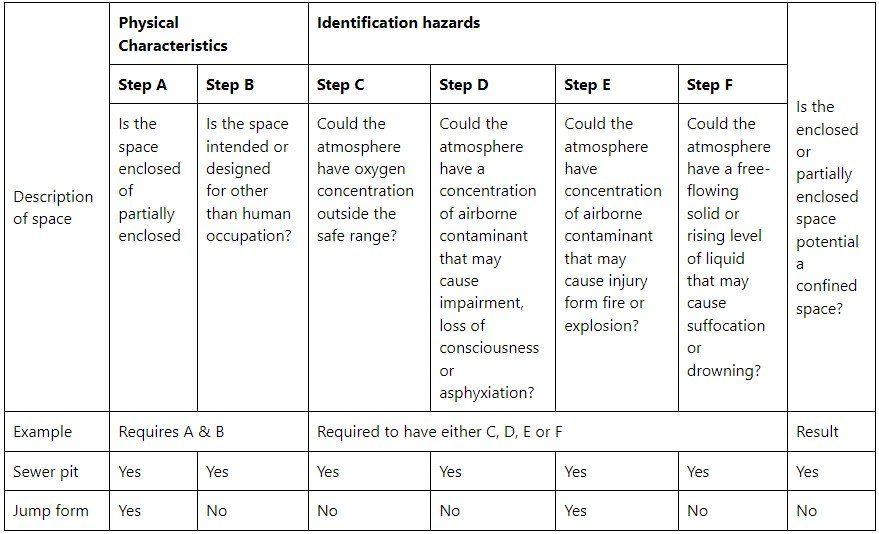

Confined Space Hazard Identification Matrix (AS 2865)

R Table 1 Confined Space Hazard Identification Matrix is used to evaluate whether or not an enclosed or partially enclosed space is understood to be confined space.

Table 1: Confined Space Hazard Identification Matrix

Notes:

- Confined space = A + B + (C or D or E or F)

- The hazards identified in steps C to F should be confirmed by risk assessment

- In the event that any questions is answered ‘no’ the a reason must be provided

Planning

As far as practicable, potential confined spaces must be identified during the design stage by the project management team and where possible designed out.

Confined spaces that are identified during design and planning stages must be assessed and appropriate strategies developed to control risks if workers are to enter and work in this space.

Compliance with AS/NZS 2865 is mandatory; a copy of the standard must be available on site.

R Confined space hazard identification matrix must be completed

S A task-specific SWMS is required for confined space entry. Due consideration must be given to but not limited to the following points:

- Access / egress

- Potential atmospheric contaminants and monitoring required (equipment)

- Ventilation

- Lighting

- Isolations of any service or source of energy

- Stormwater

- Type of work (e.g. hot work)

- Plant and equipment

- Number of personnel required

- Personal protective equipment and any limitations

- Signage and barricades

- Communication equipment

- Traffic management, and

- Emergency retrieval equipment.

- Emergency equipment and necessary standby personnel to rescue workers

- Engulfment of a person

- Whether purging or cleaning in the confined space is necessary

R People entering or carrying out work in a confined space (including the sentry/spotter) must be inducted into applicable SWMS and hold valid records of competency / training. Evidence must be retained on site, refer to:

A calibrated gas monitor must be maintained on site if work is to be carried out in a confined space

Operational – Prior to Entry

P Permit to work – Confined Space Entry must be implemented prior to any person entering a confined space. The Permit must be maintained for the duration of confined space work.

Confined space entry must only be permitted if authorised by MPX.

Confined spaces must be signed – ‘CONFINED SPACE ENTRY BY PERMIT ONLY’ or similar.

Isolation of any service/energy source must be verified.

Ventilation systems (e.g. mechanical) must be available and used as required.

Communication systems be established between the sentry/spotter and the people occupying the confined space.

Emergency procedures must be developed and implemented.

Serviceability of rescue equipment must be verified.

Gas detection equipment must be calibrated and records maintained. Refer to:

Operational – During Occupancy

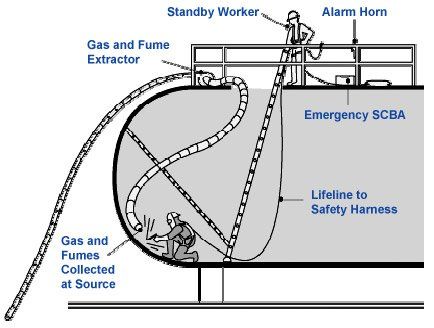

A sentry/spotter must be nominated and remain at the entry at all times whilst a confined space is occupied.

R A log of entry and exit times and dates must be maintained.

R A log of atmospheric monitoring must be maintained by the subcontractor (prior to and during occupancy).

Air quality levels must be undertaken prior to entry and at regular intervals.

Persons who work in confined spaces must maintain a serviceable gas monitor in the space they are working.

Serviceable rescue equipment must be available and set-up at the entrance to the confined space ready for use, should an emergency arise, equipment includes:

- Communication equipment

- First aid

- Fire extinguisher CO2 not permitted

- Gas monitor

- Lighting / torch

- Rope rescue set and tripod – where applicable

If the environment or conditions change work must cease. The work and associated risks must be re-assessed the revised risk assessment must be documented.

The confined space permit must be closed out once the work has been completed.

Chemicals used inside the confined space must have the SDS attached to the SWMS and Permit.

Any hot works in a confined space must be in accordance with:

- Section: Hot work.

Rescue Prevention

In the event a gas monitor alarm activates / sounds indicating a potential emergency, all personnel must leave the space immediately.

If the sentry/spotter recognises a hazard that may affect confined space workers, workers must leave the space on instruction from the sentry/spotter.

If confined space workers believe they may be in danger because they’re experiencing physiological difficulties such as excessive sweating, headaches, nausea or heat stress, they must leave the space immediately.

If at any time there is a questionable action or non-movement of a confined space worker, the other workers or sentry/spotter must carry out a verbal check. If there is no response or questionable response, the space must be evacuated.

Personal Protective Equipment (PPE)

PPE must be available for all persons involved in confined space entry including

- Breathing apparatus (where required)

- Respiratory protection

- Safety harness & lanyards / life line

- Eye protection

- Hearing protection

- Safety helmet

- Hand protection, and

- Protective footwear

Legal and Other Requirements

- AS/NZS 2865 Confined Spaces

- Confined Spaces Code of Practice (QLD)

- Confined Spaces Compliance Code (VIC)

- Confined Spaces Code of Practice (NSW)

- Confined Spaces Code of Practice (ACT)

- Confined Spaces Code of Practice (SA)

Document Control

Version 1 August 2019 – New Standard