Placement - Concrete

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Operational

E A Qualified Person (structural engineer) must inspect the steel reinforcement and provide a written report, certificate of compliance or similar to MPX prior to the placement of concrete.

- The report must state that steel reinforcement has been installed as per design / construction drawings.

R A pre pour checklist must be completed by MPX and subcontractor prior to the placement of any concrete. Concrete placement is not permitted unless authorised by MPX.

An exclusion zone must be established below suspended formwork prior to pouring concrete.

The form worker must monitor the formwork during concrete placement. Any displacement of formwork must be reported to MPX immediately.

Concrete must be placed in a controlled manner as per the formwork design, allowing concrete to flow evenly across the formwork, heaping must be avoided.

P WA - Where concrete pours that are scheduled to occur out of hours e.g. early or late pours, an Out of hours permit must be implemented.

Pump blowback is permitted providing it is blown back into the agitator barrel or other approved method by MPX.

Concrete placing equipment refer to:

- Section: Plant and Equipment Concrete Boom Pumps.

- Section: Lifting Equipment

Concrete Slabs

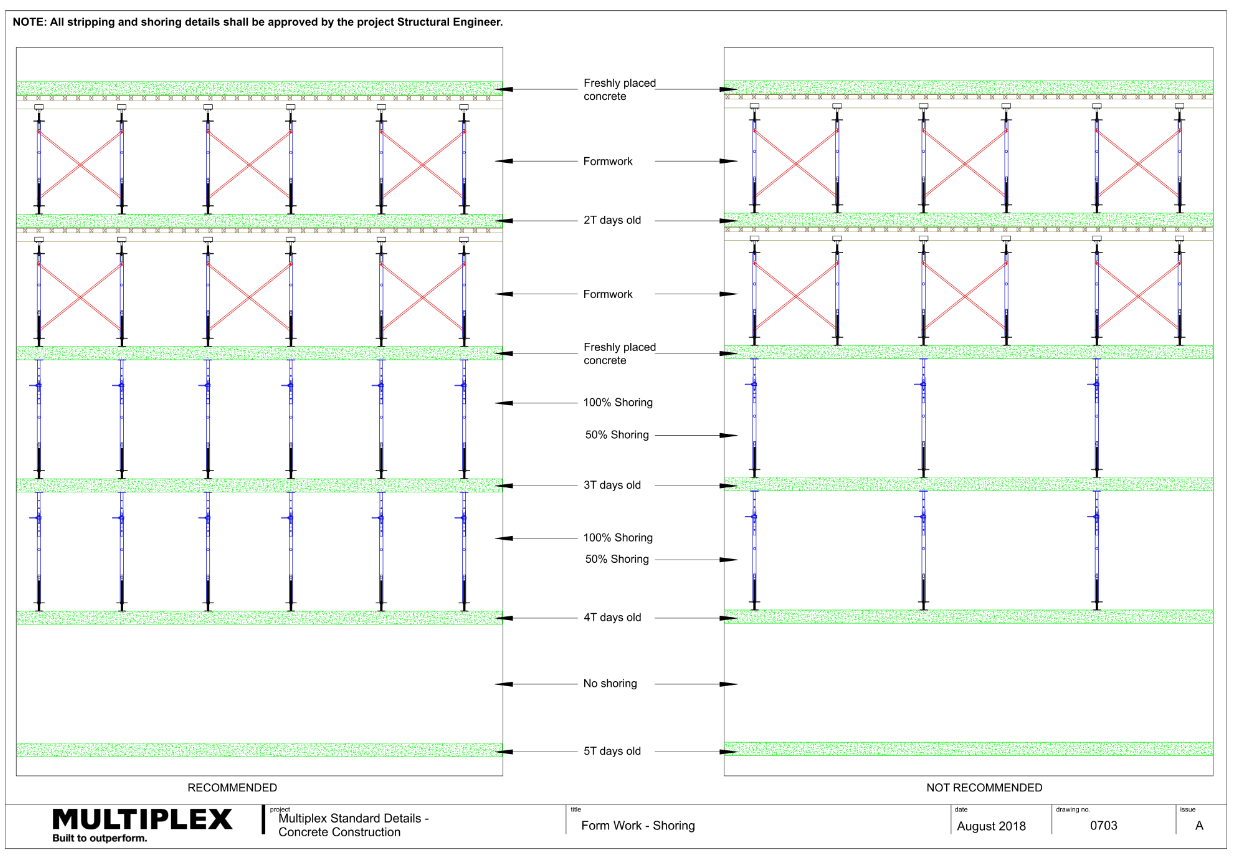

E Proposed back propping design to be submitted by formwork contractor’s temporary works engineer to the structural design engineer for approval, prior to loading.

R Prior to loading a concrete slab (eg. mobile plant, plant and equipment) the compressive strength test results and back propping requirements must be verified by a Competent Person

Stripping and Lowering

R Prior to stripping formwork the concrete compressive strength test results must be verified by a Competent Person (Site Engineer or Project Engineer or Project Coordinator).

Stripping must be in accordance with the engineer’s specification.

Prior to stripping, edge protection must be installed on slab edges and where applicable penetrations.

Exclusion zones must be established prior to stripping any formwork, with barricading (flags/parawebbing), and signage that states ‘Danger formwork stripping in progress – authorised entry only’ or similar.

Exclusion zones must remain in place until all stripping and associated activities have been completed. The formworker is responsible for maintaining exclusion zones.

Under no circumstances is ‘drop’ stripping permitted.

Stripping must be carried out in a sequential manner. Stripped formwork must be neatly stacked, floors must be left clean and all debris removed. Timber / ply sheets etc. must be de-nailed prior to stacking.

Only people involved in stripping are permitted in stripping work areas.

If any prop or other type of temporary support is required to remain in place it is to be marked and/or securely fastened in position.

Document Control

Version 1 August 2019 – New Standard