Cantilevered Crane Loading Platforms (CCLP)

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

Cantilevered crane loading platforms are generally cantilevered off a building floor (suspended concrete slab) to form a temporary platform to allow materials and equipment to be directly loaded on to or unloaded off floor levels by cranes.

Design

E Cantilevered crane loading platforms must be:

- Designed by a Qualified Person (engineer)

- Detailed on up to date drawings/plans

E Engineer certified installation drawings must be provided and retained on-site.

E Crane loading platforms must be designed to:

- Withstand both uniformly distributed loads and point loads.

- Prevent overturning, uplift or sliding:

The whole structure and any part of the crane loading platform must remain stable.

E A Qualified Person (engineer) must confirm suitability of the support structure.

E Changes to the design or installed CCLP must be authorised and signed-off by a Qualified Person (engineer).

Supporting Structures

E Supporting structures must be structurally able to withstand the loads on the platform, including at the anchor points. The loads imposed by the loading platforms on the permanent support structure must be reviewed and "signed off" by a Qualified Person (engineer).

Holes drilled in slabs for anchoring must be at locations specified by the Qualified Person (structural engineer) or, if this is not possible, at locations where a Qualified Person (structural engineer) has determined that the structural integrity of the slab will not be affected.

The means of support may be one of the following or a combination of:

- Bolts or needle supports anchored through the supporting structure, and/or

- Props (individual or manufactured propping system), secured at the top and base against lateral displacement

Installation

S A task-specific SWMS is required for installation, maintenance and removal of crane loading platforms, SWMS’s must be submitted to MPX for review prior to the installation of a crane loading platform.

R People carrying out crane loading platform work must be inducted into applicable SWMS hold a current high risk licence or record of competency / training. Evidence must be retained on site:

- Refer to Training and Competency Schedule (i.e. Riggers, scaffolders). Installers must hold a Basic Rigging (RB) or Intermediate Scaffolding (SI) HRWL

Platform landings must be flush with the floor slab or have suitable ramps installed.

There must not be any gap between the side of the platform and the side guardrails, through which a person, materials, equipment or tools can fall.

Solid panels not less than 1 m high must be fitted to the sides of the landing and extend at least 300 mm inside the building edge.

The landing edge of the loading platforms must be fitted with inward opening gates that can be prevented from opening beyond the edge of the platform by a stop fixed to the floor and restraining chains.

Gates must be closed at all times except for extended loads

A SWMS is required when gates are opened, and workers are required to be harnessed to the designated anchor points on the loading platform.

- Platforms facing a public roadway must not extend beyond the line of the overhead protection provided for the public.

- Where non-retractable platforms are used on a building face, no part of any platform must be directly beneath any part of another platform, scaffold or other work platforms.

- Retractable platforms must not be placed directly beneath a scaffold or other working platform. They may be placed one above the other but generally only one such platform must be extended at any one time.

- When more than one platform is extended, exclusion zones must be in place (above and below) for the safe placement of materials.

- Extension and retraction of crane loading platforms must be approved MPX.

- Platforms must only be used in the manner for which they were designed. Any alterations or different use of the CCLP’s should only be completed if there is a specific engineered design.

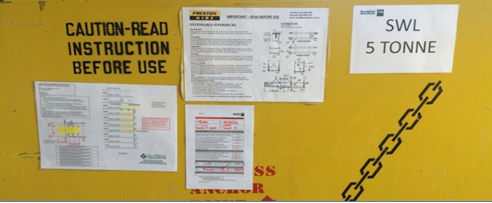

Signage

A minimum of two signs must be located on the platform stating the platform's maximum Uniformly Distributed Load (UDL) and maximum point load in characters at least 100 mm high. These loads must be marked in tonnes or kilograms.

R VIC - The following documents should be displayed in a waterproof sheet on each loading bay:

- Safe Working Load of the platform

- Multiplex Cantilevered Loading Bay Checklist.

- Operational and Safety Instructions of how to use and lift the CCLP (Supplier)

- Engineers computations/specifications

Handover / Inspection

R VIC and QLD - A cantilevered loading bay checklist must be completed

R NSW and WA - When installed, a handover checklist must be provided by the approved installer. The handover checklist must be countersigned by a Competent Person (ie. Rigger) and must include, but not be limited to the following:

- Installation in accordance with certified installation drawings and engineers support structure conditions

- Platform landings flush with floor level (ramps fitted otherwise)

- Adequate fall protection either side of loading platform

- Solid panels on loading platform are not <1m in height and extend at least 300 mm inside buildings face

- Landing edge fitted with inward opening gates that cannot open beyond platform edge

- Platforms do not extend past overhead protection (gantry) provided for public

- Signage indicating maximum uniformly distributed load (UDL) and maximum point load visible

- All props are plumb and positively secured in position

- All bolts or connection are secured and tightened in position

- Rear guardrails are in position, and:

- Side panels and gates are positively fixed in position.

R Periodic inspections of the crane loading platform must be carried out by a Competent Person refer to:

Use

- Access to the CCLP must be restricted to persons carrying out the dogging work whilst loads are being slung or unslung and/or whilst loads are being lowered or hoisted. Other persons are not permitted to be on the platform until the load/material is safely landed.

Legal and Other Requirements

- AS/NZS 1170: Structural Design Actions

- AS 1418.1: Cranes, including Hoists and Winches – Part 1: General Requirements,

- AS 1538: Cold-formed Steel Structures

- AS 2550.1: Cranes, Hoists and Winches – Safe Use – Part 1: General Requirements

- AS 4100: Steel Structures and

- AS 4991: Lifting Devices.

- Managing Risks of Plant Code of Practice (Qld) 2013

Document Control

Version 1 August 2019 – New Standard

Version 2 November 2023 – Additional requirements have been incorporated that restrict access to the CCLP to persons carrying out the dogging work whilst loads are being slung or unslung and/or whilst loads are being lowered or hoisted