Lockout, Tag-out and Service Isolation (WA)

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Note: This procedure only applies to WA

Hazards

Potential hazards include, but are not limited to:

- Live services

- Stored energy.

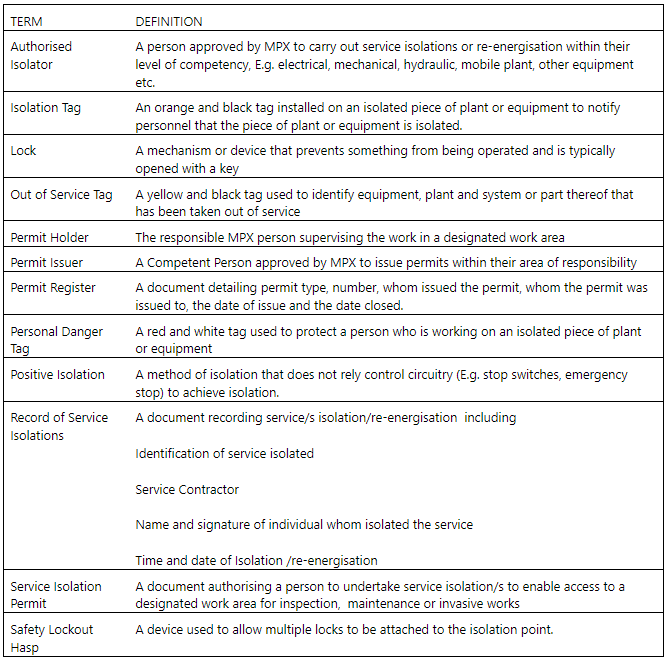

Table 1: Terms and Definitions

Planning

Work health and safety regulations identify that, if access is required for the purpose of maintenance, cleaning, repair or construction, the item of plant must be stopped and one or more of the following controls used to minimise risk:

- Lockout or isolation devices

- Danger tags

- Permit to work systems

- Other control measures

Operational

Where persons identify a fault in an item of plant or equipment the item must be shut down and an out of service tag must be attached to the main point of isolation.

Where persons are working on plant or equipment (or part of) and there is a potential for the plant or equipment to be energised, isolation / personal danger tags and locks or similar must be used.

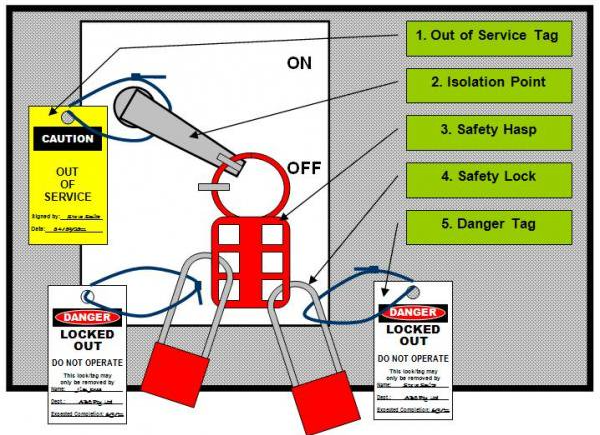

Out of Service Tags

This tag has a yellow background with black text and is used to identify equipment, plant or systems or part thereof that has been taken out of service.

- The ‘Out of Service’ tag may be used as a standalone tag or be used in conjunction with other tags or permits

- It can be applied by anyone where there is a need to prevent a piece of defective equipment from being used

- It is important that all the required information is completed and is clear, concise and legible

- Where applicable, the supervisor must be informed that the tag has been placed, so that appropriate action can be taken for the repair/replacement of the item

- Out of Service tags can only be removed by a person who is deemed competent to evaluate if the equipment is safe for use.

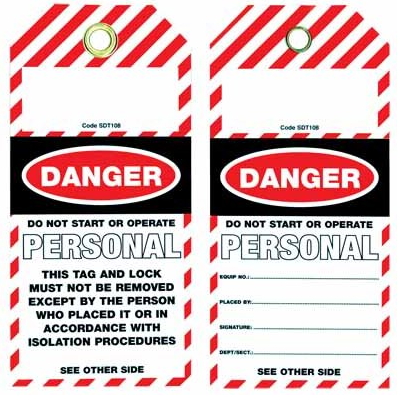

Personal Danger Tags (and locks)

This tag has a red and white background with black text and incorporates the word “DANGER” in white text on a red background:

- The Personal Danger Tag (PDT) and Lock is used to protect a person who is working on/in an isolated piece of plant or equipment

- No person must cause the status of any equipment to be altered (moved or energised) while a Personal Danger Tag is in place

- When using a Personal Danger Tag, all details on the tag must be completed fully and be legible

- Personal Danger Tags and locks must be removed from any isolation point by the person who placed the tag / lock when they are leaving the equipment, area or task at the end of their shift, and if the job/task is incomplete, must leave the Out of Service Tag in place

- Only the person identified on the Personal Danger Tag can place and remove the Personal Danger Tag i.e. the person who placed the tag is the only person who can remove the tag

- In the event the person identified on the Personal Danger Tag is absent, protocols are covered in breaches of isolation procedures.

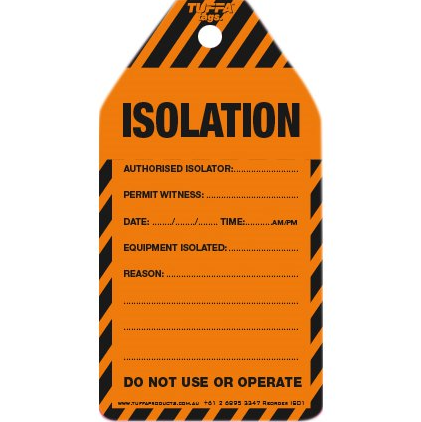

Isolation Tag and Lock

The Isolation Tag has an orange background and black text and incorporates the words “DO NOT OPERATE”:

- The Isolation Tag and a Black Isolation Lock is used to protect personnel utilising a lock out box

- The Isolation Tag and Lock must only be placed by an Authorised Isolator

- No person must cause the status of any equipment to be altered (moved or energised) whilst and Isolation Tag and Lock are in place

- An Isolation Tag and Lock may only be removed once the task is completed and all Personal Danger Tags and Locks have been removed from the Lock Box and the Isolation Permit has been closed

- Only the person identified on the Isolation Tag or the installer of the Isolation lock can place and remove the Isolation tag or lock i.e. the person who placed the tag or lock is the only person who can remove the tag or lock.

Isolation Hasp

An isolation hasp is typically used at an isolation point, when two or more personnel are working on the same item of equipment that requires isolation.

Hasps are not to be connected to one another

Lock Out Box

A lock out box is typically used when multiple workers are working on the same item of equipment or system in some cases with multiple lock out devices.

Master keys to lockout devices or equipment are placed in a lockout box.

Each worker involved then places his own personal lock on the box.

When each worker's task is completed, they remove their personal lock. When all locks have been removed, an authorised supervisor verifies all have been completed and no person is at risk.

Positive Isolations

A positive isolation must always be undertaken at the energy source and not rely on such items as control circuitry e.g. stop switches, interlocks, emergency stops, etc. These items must not be used as means of ‘positive isolation’.

To achieve positive isolations, initiate the following:

- Isolate the energy source

- Tag to identify the isolation (isolation tag)

- Test to prove the isolation is effective (some equipment may have to be put in to test mode and bump started)

- Wherever, practicable, isolations of existing equipment must be secured by use of a locking device that requires the use of a key

- Due consideration is to be taken when a pipeline isolation is being carried out, e.g. upstream and downstream flows and stored energy:

- Systems may have to be put on bypass, recycle or purge

- Low spots that may not drain down (pipe still holds product) to be emptied

- Valves can be a positive isolation but due consideration must be given to the use of spades, spectacle blinds or blank flanges.

Removal of Personal Danger Tags and Locks

All personnel must remove their Personal Danger Tag and Lock, on completion of their task or at the end of each shift, whichever comes first. If work is not completed by the end of their shift, they must remove their Personal Danger Tag and Lock. The out of service tag will remain in place.

Only the person who placed the Personal Danger Tag and Lock can remove it.

Destruction of Tags

It is intended that tags manufactured from paper be regarded as disposable and be destroyed immediately after use to prevent the possibility of re-use.

Permit to Work – Service Isolation

P Where a person/s (MPX or subcontractor) requires access to a defined work area in order to carry out work where energised services are present they must request service isolation by completing and submitting a Service/s isolation permit

MPX management representative/s must be nominated to receive and issue Service/s Isolation Permits for each project.

The workforce must be informed of the service isolation permit to work management procedure via general safety induction / project induction.

Service trades must nominate authorised isolators for services under their scope of work.

S Services trades isolating their own services are not required to complete a service/s isolation permit. The service trades SWMS, lockout and tag out procedures etc. remain applicable.

If services are identified in relation to other permit to work processes (e.g. excavation, concrete – drilling, cutting, coring, LV/HV switch room access, outrigger - mobile crane, piling rig etc.) a risk assessment must be conducted to determine service isolation requirements.

Request for Service Isolation

P The person requesting service isolation must complete Section 1 of the Service/s Isolation Permit:

- The permit number

- Name of person requesting, contact number and signature

- Contractor /company name

- The date of the request

- The name of the MPX supervisor responsible for the area/zone

- The location and description of work

- The date and time range required for the service/s isolation to be in place.

The permit number must be the next consecutive number on the Permit Register. The permit request number must be recorded on the Service/s Isolation Permit and in the Permit Register by the person requesting the Service/s Isolation Permit.

The request for service/s isolation must be submitted to the nominated MPX management representative.

A minimum of twenty four (24) hours’ notice must assess the request and complete service/s isolation, unless authorised by the MPX Project Manager or his/her delegate.

Received Request for Service Isolation

P The nominated MPX management representative must receive the request for service isolation, conduct an assessment to identify which services (if any) require isolation, whether or not any service must remain energised and if the site, part of the site, facilities, other trades or client operations will be affected by the service isolation. This assessment must be recorded on the Service/s Isolation Permit Section 2A

Notification of Service Isolation/s

R Where any service isolation/s affect the site, part of the site, facilities, other trades or client operations, MPX must notify those affected prior to carrying out isolations. The notice must detail the extent and duration of the service isolation and emergency contacts.

- Due consideration must be given to scheduling service/s isolation outside standard / normal operational hours in order to minimise impact.

- Where client operations are potentially affected, authorisation to isolate from the clients representative must be received in writing. Where applicable the client’s isolation / permit to work process must be followed.

Permission to Isolate Service

Permission to isolate services must be granted by Permit Issuer.

P The permit issuer must record on the Service/s Isolation Permit Section 2B, their name, date of authorisation, signature, name of the permit holder (MPX area/zone supervisor) and the period of time that the permit must be valid.

The permit issuer must inform the permit holder of the intent to isolate services.

Authorised Isolators must be identified.

The Authorised Isolators must record their name, signature and date in acknowledgment of their responsibilities and the timeframe of permit validation.

Permission to isolate must be subject to:

- The Record of Service Isolations being completed and displayed in the defined work area

- Notification being issued to all persons (if any) affected by the service isolation and

- Any other sitespecific condition noted on the service isolation permit.

Service Isolation

Service isolation must only be carried out by ‘Authorised Isolators’

Pad-locks, multi – padlock hasps, or similar (where required) and tags must be used and secured to each services (main point of isolation).

All services must be isolated by dissipation of stored energy. This includes verifying that inertia has been dissipated in mechanical parts, parts likely to move by gravity, electrical capacitors, accumulators, springs and pressurised fluids.

Service/s isolation must be confirmed and verified to demonstrate effectiveness by ‘Authorised Isolators’.

In the case of electrical energy:

- Isolation must be accordance with Section: Isolation / Deenergisation / Re-energisation

- Whole current isolation such as the main isolator should be used instead of control isolation by way of the stop button.

Record of Service Isolation

R Records of isolations must be displayed in the defined work area. Service/s isolation register must detail:

- The service/s isolated

- The service contractor’s name (e.g. ABC electrical)

- The name and signature of the person completing the isolation (e.g. John Smith)

- The time and date of the service isolation.

HOLD POINT

- Permit issuer must verify, permit sections 2A + 2B are complete and services have been isolated.

Commencement of Work

P The permit issuer must inform the permit holder that the work as described in the request for service isolation may commence. the permit issuer must record their name, date and signature on the service isolation permit

The permit holder must record their name, date and signature on the Service Isolation Permit

The service/s isolation permit and records of isolations must be displayed in the defined work area.

The contractor or company requesting service isolation must be informed that:

- Services isolations have been implemented

- Work may commence as described in the permit

- No deviation from the work as described is permitted

- Work may only be carried out within nominated validation period.

Completion of Work

P On completion of the work (as described), the permit holder must inform the permit issuer. The permit holder must confirm the work is complete and record their name, signature and date on the Service Isolation Permit.

Where delays occur the permit holder must inform the permit issuer. The permit issuer must either re validate or cancel the Service Isolation Permit. Where the Service Isolation Permit is cancelled a new service isolation request must be generated.

Re-energisation of Services

The permit issuer must inform the service contractors that the work has been completed and the isolation can be removed and services re-energised.

A record of service re-energisation must be completed by the Authorised Isolators. They must record the time and date of re-energisation, and sign the record.

P On confirmation that all service isolations have been removed and services re-energised, the permit issuer must close out the permit and record their name; signature and date on the Service/s isolation permit

Records

R Records of service isolation/re-energisation must be kept for purpose of review and audit and be produced as and when requested.

Breaches of Isolation, Lockout or Tag-out Procedures

Breaches Generally

In cases where people fail to follow lockout, tag-out or isolation procedures they will be subject to disciplinary action.

Breaches Where Employees Are Available

Where a Personal Danger Tag and Lock has been left in situ after work on isolated services, plant or equipment has been completed, or the shift has ended, the person responsible must be called back to site to remove his/her Personal Danger Tag and Lock.

Breaches Where Employees Are Not Available

Where a Personal Danger Tag and Lock has been left in situ, and all reasonable efforts have been made to locate the person responsible, or it is not practical to return the person responsible to site (e.g. unable to return or under the influence of alcohol), the following will apply:

- The respective supervisor must verify that if the Personal Danger Tag and lock in question were removed, it would be safe to reenergise (de-isolate) the equipment isolated by that PDT and lock. The supervisor must get approval from the relevant Multiplex Site Manager.

R If the Personal Danger Tag and Lock is removed by a person other than the person whose name is on the Personal Danger Tag, the tag must be retained, an incident report must be raised and a formal investigation must take place within 24 hours of the incident.

Accidental Removal of Personal Danger Tag

In the case where a Personal Danger Tag has been removed accidentally, the following must apply:

- The person concerned must IMMEDIATELY fill out a Personal Danger Tag in their name to replace the one that was removed. The person concerned must take the incorrectly removed Personal Danger Tag to their supervisor immediately

- The supervisor must take immediate steps to advise the person whose tag was accidentally removed so that they can replace a Personal Danger Tag of their own and report to MPX Site Management.

R Where required formal investigations and incident reports must take place within 24 hours.

Legal and Other Requirements

- AS 4024.1 Safeguarding of Machinery Part 1 - General Principles

- Managing Risks of Plant Code of Practice (Qld) 2013

Document Control

Version 1 August 2019 – New Procedure