Cranes - Tower

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Note: This section is to be read in conjunction with:

Informative

Planning

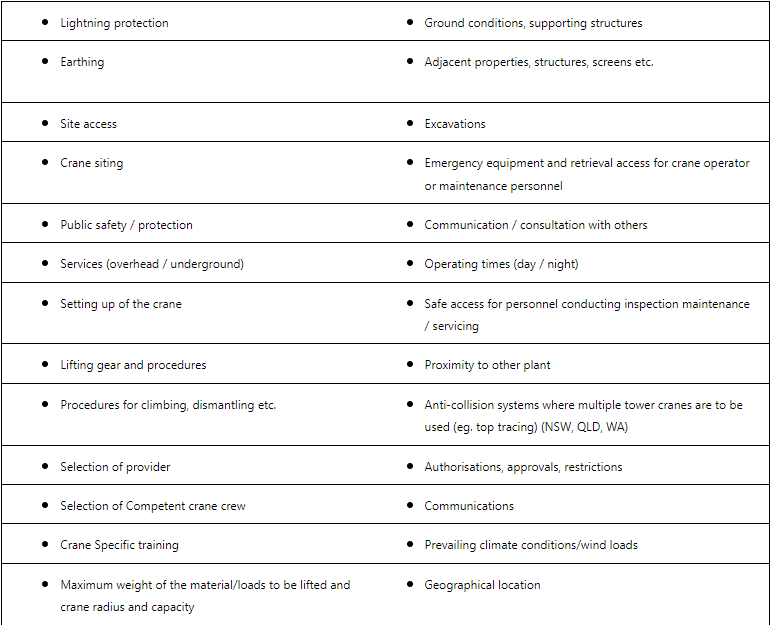

Planning at pre tender stage must consider the relevant parts of AS 2550 Cranes, hoist and winches – safe use.

R Planning and selection risk workshops must be held and documented.

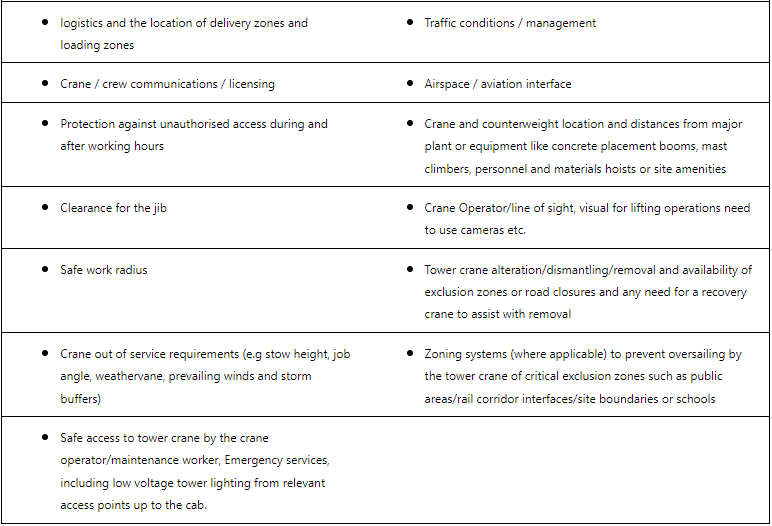

Considerations should be given to the following:

Crane Selection

Consideration should be in accordance with AS 2550 and include but not be limited to the following:

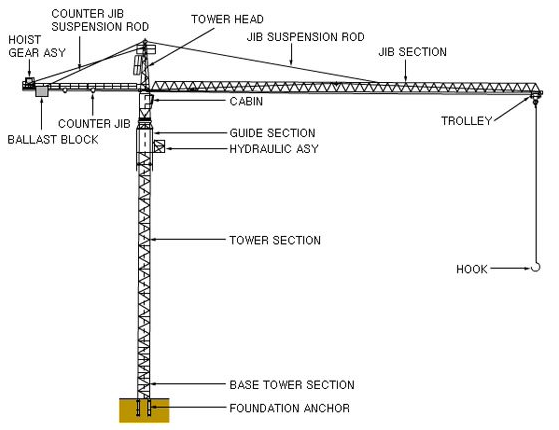

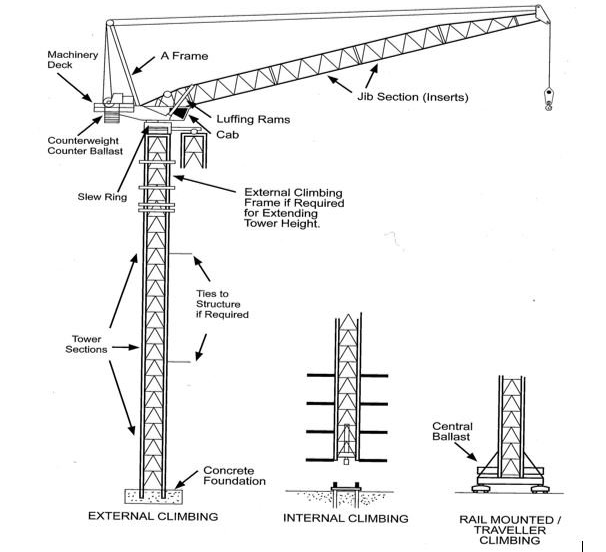

- Type of crane trolley jib, luffing etc.

- Lifting requirements, rated capacity at each radius

- Maximum crane height and hoisting height

- Maximum expected wind loading at the site

- Weather vanning, management of adverse weather conditions

- Requirements for erection, climbing, tie bracing and dismantling

- Where tie bracing used the ability of the structure to support loads

- Power source (electric, diesel)

- Maintenance / inspection /servicing requirements

- Timeframe of use.

Tower cranes operating on Multiplex projects must be fitted with:

- A anemometer (air speed gauge)

- Fire suppression mounted in the tower crane engine compartment for diesel cranes

- Fire extinguisher for electric cranes

- VIC – Fire blanket

- A Safe load indicator

- Rope counter (where applicable)

- Directional indicator

- Perimeter edge protection consisting of a top rail, a mid rail and a toe board that extends around the machine deck

Tower cranes operating in regions have the additional requirements:

- VIC and QLD - Cameras on the drum and on the hook

- NSW - Cameras on the drum and engine compartment for diesel cranes

Tower cranes required to undertake a lift or lifts that exceed the rated capacity for a specified radius (e.g. “Designed Lift”) shall be in accordance with Australian Standards AS 2550.1 (Clause 6.26 Designed Lifts).

Preventing Unauthorised Access

A secure (lockable) hoarding or enclosure is required to be erected and maintained around the base of the crane to prevent unauthorised access. The hoarding or enclosure should be of a sufficient height and constructed of a material which prevents a person climbing.

Materials / equipment should not be stored against the hoarding / structure.

Barriers or similar are required to be installed to prevent unauthorised persons from accessing the crane from the structure or ties.

A secure (lockable) trap door at the underside of the tower crane machinery deck should be kept closed at all times and is to be locked at the end of each shift.

NSW - Anti-climb panels fitted to the outside of the tower to prevent anyone climbing the structural steel members of the crane and a lockable trap door on the inside of the tower.

Training and Competency

R People carrying out TC activities must be inducted into applicable SWMS and hold valid records of training / competency. Evidence must be retained on site, refer to

R TC operator familiarisation/induction must be completed by the crane supplier.

R NSW, QLD, WA - TC operator rescue training must be completed.

R Crane crew must be inducted, SWMS reviewed and signed.

R Crane crew must be inducted into the Emergency Management Plan. The crane crew must sign off they have been inducted into the emergency management plan.

R QLD - Crane Crew Refresher Training (should not exceed 3 years)

Pre-mobilisation

E The TC standing (i.e. base/grillage) must be designed and documented by a Qualified Person (e.g.Tower Crane Engineer) the supporting foundation must be capable of sustaining imposed loads.

R The TC owner / erector must provide MPX the following information for review:

- Evidence of design registration submitted to regulatory authority

- Specifications / data sheets

- Component breakdown

- Tower crane drawings prepared and approved by the Qualified Person (e.g. Tower Crane Engineer) and include:

- Design of crane installation

- Design of crane ties and grillage, where applicable

- Crane engineer’s or manufacturer’s approval for signage

- Structural engineer’s approval of crane ties and suitability of the support structure.

- Pre-erection component inspections / tests completed incl.

- Inspection and test report obtained by an independent (third party) industry-endorsed inspector/assessor e.g. Crane Industry Council of Australia or CraneSafe prior to crane delivery that includes non-destructive testing of: for example critical welds, connectors, slew bolts etc

- Tower crane bases inspections by a Qualified Person (structural engineer)

- Power supply requirements.

R WA - The above must be referenced in Tower crane pre-mobilisation form

R NSW, QLD and VIC - The above must be referenced in the Tower crane erection form

MPX must provide TC foundation design drawings/specifications to concrete, steel fixing, earthmoving, piling and structural steel/grillage subcontractors.

Erection

General requirements for the erection of TC must be in accordance with AS 2550.1 and carried out in accordance with manufacturer’s instructions.

R WA - Erection is only permitted to commence after Tower crane pre-mobilisation form and Tower crane erection form has been completed and supporting documentation reviewed, verified and recorded.

R NSW, QLD, VIC - Erection is only permitted to commence after Tower crane erection form and risk workshop have been completed and supporting documentation reviewed, verified and recorded.

P NSW, QLD and WA - A Permit to Work must be implemented for the mobile crane/s used in the erection process.

A Competent Person appointed by the crane supplier in conjunction with MPX management must supervise the work.

Transport and stowing must be in accordance with manufacturer’s instructions and authority requirements

Commissioning & Pre-operation

R WA - A third party inspection/commissioning report must be completed and submitted to the regulatory authority. Note: Authority plant registration to be displayed (at the crane base/enclosure) when received.

R Third party inspection/commissioning report must be completed and submitted to MPX including when tower cranes are relocated on a project.

R NSW, QLD, VIC - All tower cranes erected on a Multiplex project will be assessed by an independent auditor from CraneSafe to ensure that all the relevant mechanical and visual inspections are conducted on the crane during the pre-commissioning and commissioning phases. MPX will also be required to ensure that all the relevant paperwork has been issued by the crane supplier and the structural engineer.

R TC lifting equipment register must be completed and provided to MPX.

R WA - Tower crane commissioning and handover forms must be completed after the TC has been commissioned (by a Competent Person) and, operator familiarisation and rescue training completed and the crane crew inducted – SWMS reviewed and signed.

Operational and Adverse Weather Conditions

At the end of each day:

- Chains etc. must be removed from the crane hook

- The crane boom, rope and hook are placed clear of all adjacent structures (in a 360 degree radius) as far as if practical

- For electric cranes power isolated by the operator or at the base isolation switch in cab at controls

Working deck maintained so as to be clear of debris, equipment, tools and materials

Tower cranes should only be operated in wind speeds identified in AS 1418.4 and as recommended by the manufacturer

QLD - Tower cranes are not to operate in winds exceeding 54km/hr

Where adverse weather conditions are predicted, precautions include but are not limited to:

- Chains etc. must be removed from the crane hook

- The crane be set to weather vane (unless permission is gained from the manufacturer for extenuating circumstances). In this case a Qualified Person (engineer) must provide information on how to restrict the crane from weather vaning. This information must be provided to the crane crew and MPX.

- For hammer head cranes set to trolley-in

- For luffing, jib angle set in accordance with manufacturers specification

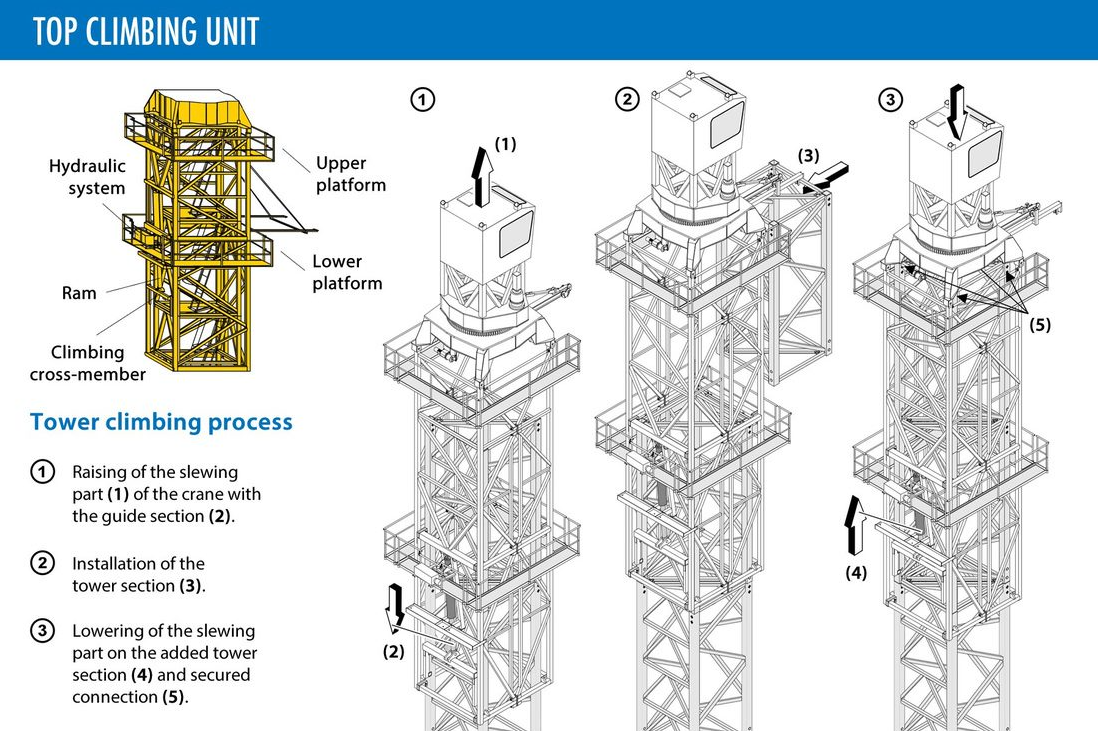

Climbing

R Tower crane climbing checklist is to be completed to verify that the risks associated with climbing have been assessed, controls, established, implemented, and relevant sections of AS 2550.4 are met.

Pre-commencement activities (e.g. weather report, permit to work, pre-start, exclusion zones, and traffic management) must be completed by MPX and the relevant contractor.

E Tie design and drawings must be supplied by the TC supplier/erector and be approved by a Qualified Person (engineer).

Use of fall arrest devices must be in accordance with AS 1891.1, refer to:

- Section: Fall Injury Prevention Systems

Climbing must be carried out in accordance with the manufacturer’s specifications and applicable drawings.

Inspections and Maintenance

Routine inspections and maintenance must be carried out in accordance with manufacturer’s recommendations and regulatory requirements, refer to:

Where replacement parts or components must be used they must meet the manufacturer’s requirements

R Maintenance records must be provided to MPX. These records should provide services details and the hours.

All safety-related malfunctions and problems (recorded in the logbook and reported to MPX) must be rectified before the crane is returned to service.

- WA and VIC MPX / crane owner must report to the regulatory authority where applicable.

Major inspections must be performed on:

- TC that have reached the end of their design life (or every 10 years after first being commissioned)

- Old TC that are to be recommissioned

- TC that are to be upgraded or modified and/or

- TC whose maintenance records indicate repeated failures (i.e. in order to assess their suitability for continued safe operation).

- QLD on second hand imported cranes

TC self-rescue kit must be inspected in accordance with

Dismantling

General requirements for the dismantling of Tower Crane must be in accordance with AS 2550.1 and carried out in accordance with manufacturer’s instructions.

R Dismantling must not commence until a risk workshop is conducted, the MPX Tower crane dismantle checklist has been completed and supporting documentation verified and recorded.

Crane modifications

R Any modification to a TC not in accordance with the manufacturer’s specifications requires certification from the crane manufacturer approving the modification.

Legal and Other Requirements

- AS 1891.4 Industrial Fall Arrest Systems & Devices Part 4 Selection Use & Maintenance

- AS 1418.4 Cranes, Hoists & Winches – Tower cranes

- AS 2550.1 Cranes, Hoists & Winches – General Requirements

- AS 2550.4 Cranes, Hoists & Winches – Safe use, Tower cranes

- Tower Crane Code of Practice (Qld) 2017

Document Control

Version 1 August 2019 – New Standard

Version 2 June 2021 - Inclusion of typical details relating to vertical support details.

Version 3 March 2022

- Update to Planning Section

- Update to Crane Selection

- Update to Operational and Adverse Weather Conditions