Post-tensioning

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Hazards

Potential hazards include, but are not limited to:

- Uncontrolled released of cable tension

- Stressing jack failure

- Wedge and socket failure.

Design and Planning

E Post-tensioning systems must be designed by a Qualified Person (engineer).

Sufficient scaffolding or over-form must be allowed for in the formwork design to accommodate post-tensioning work (e.g. typically a minimum of 800mm between the slab edge and the outside scaffold rail).

S A site-specific SWMS must be developed and implemented for post-tensioning work.

- All persons carrying out posttensioning work must be inducted into the relevant SWMS

E Structural post-tensioning drawing and specifications must be available on site, specifications must detail as a minimum the:

- Stressing sequence

- Transfer strength required (before stressing): and

- Designated loads for which the strands must be stressed.

E Stressing is not permitted to commence until the concrete has reached the required compressive strength, unless approved by the design engineer, approval must be in writing.

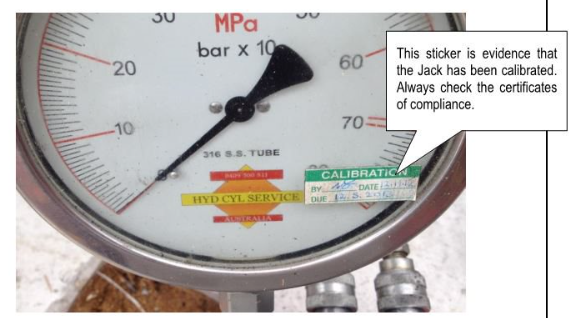

The hydraulic jack and gauge must be marked and the markings must correspond to the calibration sheet.

R The calibration sheet must detail the:

- Final stressing pressure

- Diameter and grade of the strands for which the jack is to be used

- Jack number

- Gauge number: and date the calibration expires.

Preparation

The weight of post tension equipment such as strand coil frames, anchors, tool boxes and duct must be considered when loading onto formwork.

Post tension strand coils must:

- Be restrained with uncut restraining straps when placing them onto the strand frame.

The strand frame should:

- Incorporate a wire mesh frame into the portable frame structure (Bripak) which covers the top half of the post tension coil

- VIC Incorporate a 5m length of 40mm poly pipe connection to the Bripak cone feed (where required).

Installation

Coil must be positioned on the suspended formwork deck as close as practicable to the location of which the strand is being pushed into the duct.

Strands must be pushed into the duct in accordance with the drawings.

Exclusion zones must be established during pushing operations.

During concrete pours any damaged pan ends, duct or strand must be rectified immediately by the post tension contractor.

Stressing Operations

Exclusion zones must be established and signage displayed in around stressing work zones.

Signage must state ‘Stressing in progress keep clear’ or similar.

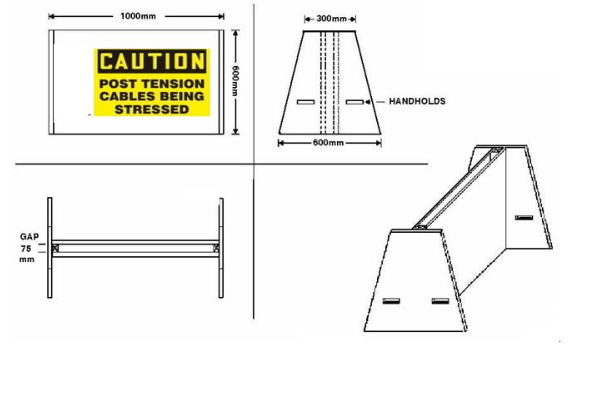

Stressing barricades (backing boards) must be set-up within two (2) metres behind any live tendon/strand end.

Hydraulic jacks and other equipment must be maintained in accordance with the manufacturers specifications, records of service and calibration must be maintained on site and be produced when requested.

Concrete around anchorages must be inspected prior to stressing, where potential defects are identified operations must be suspended and MPX notified.

Stressing must be in the sequence as detailed in the specifications, the specified initial and final stressing pressures must not be exceeded.

The stressing jack operator must make arrangements for a person to verify that the anchorage blocks and wedges are correctly seated during stressing.

Block and wedges must be verified as compatible and of the correct size.

Strands are not permitted to be cut by heat type cutting equipment such as oxy-acetylene or LPG torches, as this may compromise the load bearing capacity under tension.

E Prior to cutting off strands, the design engineer’s approval must be obtained.

As far as is practicable shearing tools should be used to cut off strand ends.

P WA - Where grinders are used to cut off strands a Hot Work Permit must be implemented.

Exposed strand ends must be taped or otherwise protected to reduce risk of injury i.e. proprietary strand caps.

Covers must be secured over stressing pans

VIC - Covers must be secured over stressing pans with a steel plate

Cables should be trimmed and concealed within the pan cover.

Grouting

Suitable PPE must be worn when mixing grout products (As per SDS).

Prior to grouting, ducts must be cleared of any potential blockage.

Grouting of each duct must be continuous and the equipment gauge must be constantly monitored.

Removal of slurry, grout tubes and strand off cuts must be carried out progressively. Grout tubes must be cut off (once filled) and pan ends grouted promptly.

Spotters must be used to monitor the progress of grout through grout tubes so as to minimise risk of spill over the building edge.

Any grout spillage must be cleaned up promptly.

R ITP’s and marked-up drawings must be provided by the subcontractor to verify that all ducts have been grouted.

Concrete Coring, Cutting or Drilling

Concrete coring, cutting or drilling into a post-tensioned slab is not permitted unless authorised by MPX.

P Where drilling, coring or cutting is authorised by MPX a Concrete Coring, Cutting and Drilling Permit must be implemented. Refer to:

Legal and Other Requirements

- AS 1314 Prestressing Anchorages

- AS 3600 Concrete Structures

Document Control

Version 1 August 2019 – New Standard