Cranes - Mobile

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Note: This section is to be read in conjunction with:

Informative

Mobile cranes include slewing, non-slewing and vehicle loading type cranes.

Other multi-purpose mobile plant, including telescopic handlers, forklifts, and earthmoving plant, may be classified as cranes in specific configurations.

Articulated non-slewing mobile cranes (e.g. pick and carry) are not permitted to be used on MPX sites unless approved by the MPX Chief Executive Officer.

- Note: VIC – An Pick and Carry Cranes (Franna) Permit to Work which is available though the Regional Health and Safety Manager must be completed prior to seeking approval.

Planning

Proximity hazards must be identified prior to set-up and before lifting. These include, but are not limited to:

- Structures (overhead /adjacent)

- Excavations

- Pits, tanks, soak wells

- The public

- Services (in ground / overhead)

- Other mobile plant / traffic

Minimum working distances (slewing area etc.) must be defined and agreed.

When planning to use mobile cranes consideration should be given to the:

- Planning requirements outlined under Section: Cranes, Hoists and Other Lifting Equipment

- The type, number and rated capacities

- The radius of the lift at the pickup and drop off locations

- Travel path of the load, including slopes to be traversed (i.e. for Forklifts/ telehandlers)

- The work environment incl. location of setup, surface & ground conditions

- The proximity of overhead powerlines

- The proximity of other cranes and/or other plant/structures

- Airspace interface

- Security

- Deliveries

- Access and egress for maintenance, adjustments, repairs, cleaning, use

- Relative height of the crane

- Impact on structures

- Maximum load radius to be used for the cranes

- Designated spotter

- Maximum wind speed / prevailing weather conditions

- Ground bearing pressure

- Allowance for any factors that may require derating of the crane (e.g. for multiple crane lifts, additional radius caused by tilting of tilt-up panels)

R Prior to use of a mobile crane on MPX projects, the crane must be registered for use on site.

P NSW, WA and QLD - A Outrigger Permit must be implemented prior to setting up a mobile crane

E Ground bearing pressure for intended loads must be confirmed prior to lifting and be in accordance with engineering/geotechnical specifications.

Where applicable lift study documentation for specialised lifts must be verified and attached to the permit (NSW, QLD, and WA) or SWMS (VIC).

Operational (Additional Requirements)

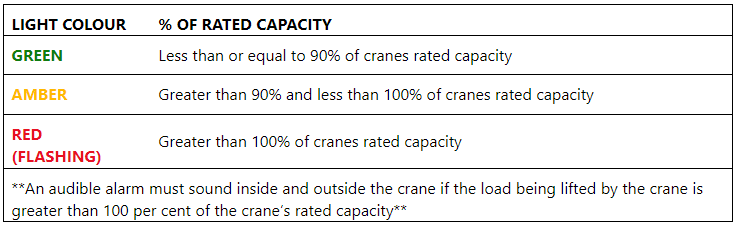

WA - where a mobile crane (other than a VLC or earthmoving machinery) is slewing or is non-slewing with a maximum rated capacity of greater than 20 tonnes the crane must be fitted with green, amber and red load warning lights on the outside and visible from the inside the cab to show what percentage of the crane’s rated capacity being lifted.

NSW, VIC and QLD - Where a mobile crane (other than a VLC or earthmoving machinery) is slewing or is non-slewing, the crane must be fitted with green, amber and red load warning lights on the outside and visible from the inside the cab to show what percentage of the crane’s rated capacity being lifted.

Table 2 – Load warning lights

Where other mobile or fixed plant is operating in the area, suitable communication (e.g. two-way radios, horn or hand signals – where in direct line of sight) must be established between the plant operators.

A crane coordination plan/ procedures must be established where there is a shared space airspace with other plant (e.g. crane, concrete boom).

Suitable exclusion zones must be established, including traffic management, refer to:

- Section: Barricading and Signage.

Legal and Other Requirements

- AS 1418.1 Cranes, Hoists & Winches - general requirements

- AS/NZS 2550 Cranes safe use

Document Control

Version 1 August 2019 – New Standard