Manual Handling (Hazardous Manual Tasks)

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

To eliminate or reduce manual handling risks, suitable controls in consultation with workers need to be developed> the following 3 questions should be considered:

- Is the manual handling activity necessary?

- Can the work task be changed to eliminate, reduce or control the risk of injury?

- What are the manual handling training needs of the task?

Hazards and Risks

Potential hazards and risks include, but are not limited to:

- Musculoskeletal Injuries

- Slips, trips and falls

Definition

Any task that requires the use of physical exertion by a person to lift, move, carry, push, pull or restrain any object, person or thing. It may include:

- Repetitive or sustained force

- High or sudden force

- Sustained or awkward postures

- Exposure to vibration.

Planning

Where applicable consideration should be given to controlling manual handling related risks when:

- Purchasing new plant and equipment

- Specifications are given to suppliers regarding how equipment and products are to be packaged, and the way they are to be delivered

- Designers and engineers are required to design or modify tasks, work processes at the design stage

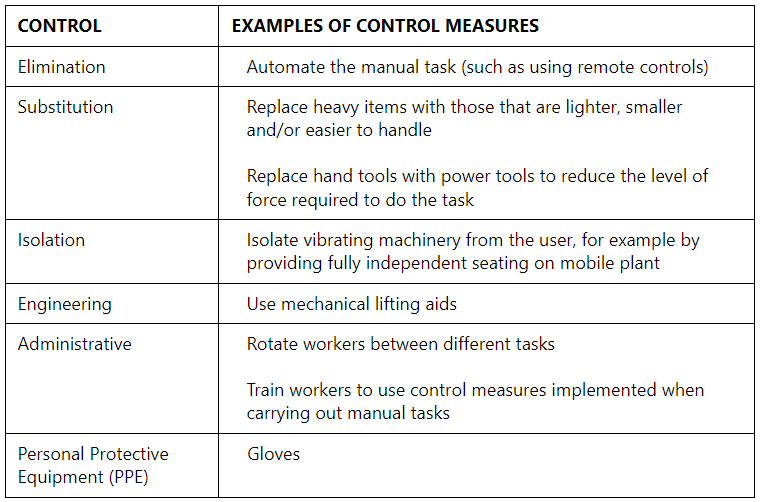

The risks associated with manual handling must be identified, assessed and controlled in accordance with the Hierarchy of Control outlined in Table 1.

TABLE 1: MANUAL HANDLING HIERARCHY OF CONTROL EXAMPLES

Where a crane or forklift etc is used, the operator must hold the applicable license or record of training, refer to:

People who are required to perform hazardous manual handling tasks should be consulted and adequately trained in performing the tasks safely.

Contractors must have available trolleys, wheelbarrows or similar, in a serviceable condition for use when transporting heavy, awkward or bulky items.

Heavier items should be organised to be delivered as close to the working area as possible to eliminate double handling (but not in access ways).

Clear access to work areas must be maintained.

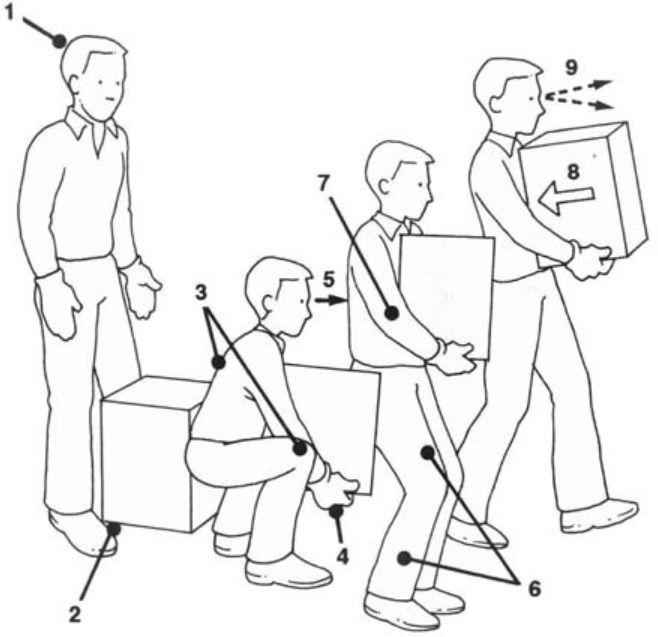

Operational - Manual handling technique

- Assess the load and your pathway prior to lifting.

- Avoid reaching out, get as close to the load as practicable.

- Position your feet shoulder width apart, one foot slightly in front of the other.

- Avoid bending by crouching down, remembering to keep your back straight, bending at the hip and knee joints (keeping your shoulders back, head up and tucking your chin in, assists in keeping your back straight).

- Get a good firm grip of the load to achieve even distribution of weight.

- Lift the load keeping it close to the body.

- Avoid twisting, to change direction move your feet.

- Place loads down, do not drop them. Bend at the hip and knee joints keep your back straight.

- Avoid lifting above your shoulders.

- Team lifting should be exercised if loads are long or awkward, delegated leader to signal instructions.

Legal and Other Requirements

- CP Manual Tasks 2010

- Hazardous Manual Tasks Code of Practice (Qld) 2011

Document Control

Version 1 August 2019 – New Standard

Version 26 May 2023 - Removed the QLD requirement to perform a risk assessment and for the safety in design risk assessment to consider hazardous manual tasks.