Cranes, Hoists and Other Lifting Equipment - General

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

Multiplex Crane Induction Part 3

Hazards

Potential hazards include, but are not limited to:

- Equipment failure

- Equipment collapse / tip over

- Falling objects

- Fire

- Proximity hazards.

Planning

Risk workshops for cranes and hoists must consider:

- The type, number and rated capacities

- Location and siting

- Access

- Loads

- Relative height

- Impact on structures (ties etc.)

- Power supply

- Environmental factors

- Proximity hazards

- Equipment, lifting accessories and personnel

- The need to conduct a site inspection

- Lift study/plan for specialised lifts

Consider applications of other equipment configured as a crane.

S A task-specific SWMS is required for all crane or hoist operation or dogging work or other lifting equipment.

R Cranes or hoists must be site registered by MPX and all relevant checklists and associated documentation completed and submitted prior to use on MPX projects.

For all multi-crane lifting a lift study must be completed by a Competent Person.

Each mobile crane supplier, subcontractor or MPX must determine whether a documented lift study/plan is required.

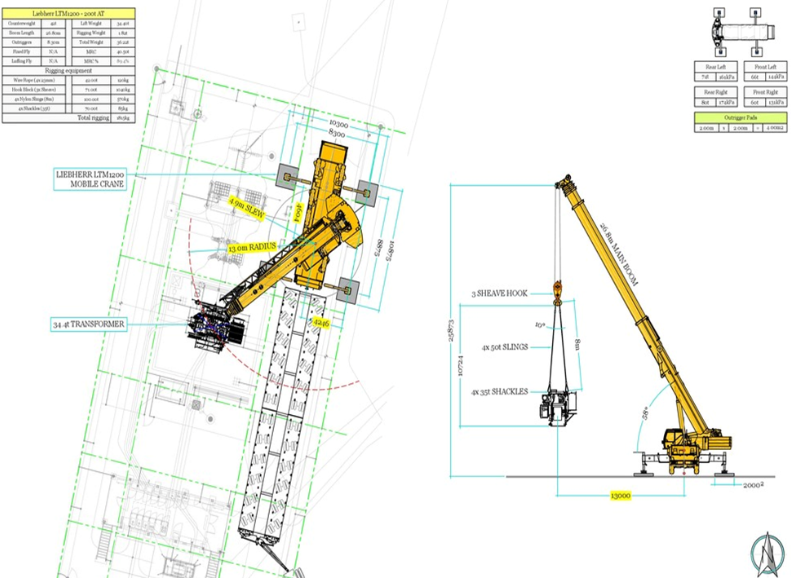

E Lift study/plan must be documented (for specialised lifts) by a Competent Person from the designated crane supplier or their engaged party for specialised lifts and include details, as per AS2550.1 such as: lifting and rigging configurations, radius of lift and swl, load weight, ground conditions etc

R A lift study must be provided where required for all specialised lifts.

Specialised lifts – include where:

- Multiple cranes are used

- Load mass is uneven/an irregular shape requiring load sharing devices (such as equalizing beams)

- Lifting precast concrete panels

- A crane has a limited duty cycle (e.g. A limited proportion of time during which the crane can operate for before it must cease operation/rest)

- Erecting, dismantling, climbing tower cranes or tie install

- Demolition of structural elements

- Lifting hazardous goods or items of high monetary value/ long procurement lead times

- Load is ≥90% of the rated capacity of the mobile crane (NSW, VIC and WA)

- Lifts of 50t or more (QLD)

- Workbox used with a mobile crane (QLD)

- Working near overhead powerlines (QLD)

- Use of mobile cranes on barges (QLD)

Click on image for an enlarged version

Consultation must take place with all interested parties potentially impacted by the works and permits (where applicable) obtain the relevant permits from the Civil Aviation Safety Authority and other regulatory authorities.

Training and Competency

R People operating cranes or hoists or carrying out dogging work must be inducted into applicable SWMS and hold valid records competency / training, evidence must be retained on site. Refer to:

Operational

Cranes, hoists and other lifting equipment must be inspected, maintained and operated in accordance with the manufacturer’s instructions, regulatory requirements and applicable Australian Standards, refer to:

The manufacturer’s operations manual must be available with the crane, hoist or other lifting equipment.

- Where the manufactures instructions are not available, then in accordance with relevant parts of AS/NZS 2550 and AS 1418 and applicable regulatory requirements.

R Maintenance and inspection records must be retained on site, including NDT records.

Cranes should at all times operate within specified working limits and not exceed their rated capacity. Over lifts are only permitted if they are approved by the crane manufacturer or Qualified Person (E.g. Tower Crane Engineer).

The applicable load chart must be provided with the crane.

A crane, hoist or other lifting equipment must not be left unattended while in use.

R Crane/hoist operators must fill out the equipment’s daily inspection logbook.

- VIC- Copies of the logbook must be issued to MPX at the end of each week.

R Faults or issues must be reported to MPX and Supplier without delay and recorded in the logbook.

Directions to crane operators must only be made through two-way radio communication or via use of hand signals.

The dogmen / rigger may direct the crane through two-way radio communication or via use of hand signals (note: only permissible when the operator and dogmen / rigger have direct line of sight).

The Safe Working Load (SWL) limits must be displayed on any plant that lifts.

Plant (ie MEWP) that is lifted must have an approved certified lifting point/s and inspected every 12 months.

As far as is practicable, loads are not to be lifted, suspended above or travel over people.

All loads must be appropriately restrained.

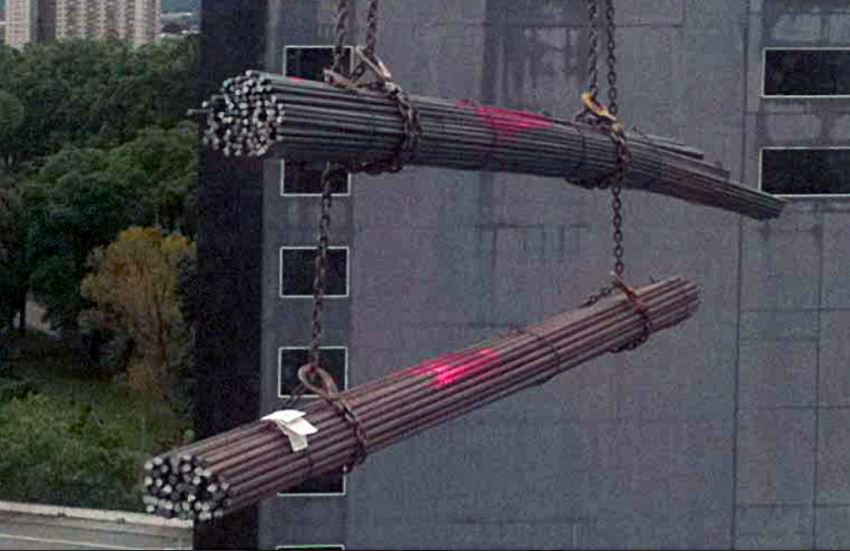

"High/Low Lift”, commonly known as a “Christmas Tree Lift” or “Piggy Back lift”,i.e. where 2 or more loads are slung in a vertical configuration from a crane hook in a single lift are not permitted.

Suitable exclusion zones must be established for mobile crane set-ups, including traffic management (where applicable). Refer to:

- Section: Barricading and signage.

Tag-lines must be used as far as is practical on suspended loads.

Local wind speed must be monitored continuously by the designated MPX site manager/supervisor, the crane operator and rigging crew. If conditions become hazardous, lifting must cease and the work / work area made safe. Loads are not to be lifted in adverse weather conditions (e.g. strong winds, lightning), until such time that the winds have either eased or ceased and it is safe to operate a crane again.

Minimum distances must be defined for working adjacent to proximity hazards (e.g. overhead power lines, other structures), refer to:

Legal and Other Requirements

- AS 1418.1 Cranes, Hoists & Winches - general requirements

- AS/NZS 2550 Cranes safe use

Document Control

Version 1 August 2019 – New Standard

Version 2 29 October 2021 - Inclusion of the requirement for "High/Low Lift”

Version 3 9th May 2022 - Inclusion of the consideration for risk workshops to be held for other equipment configured as a crane and reference to AS2550.1 for details relating to lift studies/plans.