Forklifts / Telescopic Handlers

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Note: This section is to be read in conjunction with:

- Section: Cranes, Hoists and Other Lifting Equipment

- Section: Mobile Plant

Operational

Forklifts must:

- Comply with the requirements under the section: Plant and Equipment

- Be fitted with a data plate that indicates:

- Load capacity at different mast angles or when it is fitted with an attachment

- De rating for specific attachments

- Be fitted with catalytic converter if fuelled by diesel

- Have designated work areas, load and laydown areas established where practical.

- NSW Be fitted with a backrest apron

Extension Tines

Where extension tines or similar are used on forklift / telescopic handlers:

- The parent tines/forks must support at least 60% of the overall length of the slipper

- The extension tines must be secured to the forklift / telescopic handler tines with a locking pin – to stop the tines from moving during operation

- The extension tines must be compatible with the type of plant and be fitted with a data plate displaying the SWL

- When operating a forklift or telescopic handler with extension tines, the forklift or telescopic handler operator must remain cognisant that loads applied towards the outer edge of the extension tines will increase the load weight and therefore must not lift materials close to or equalling the SWL. Where operating a telescopic handler, the operator must refer to the load chart located within the cab.

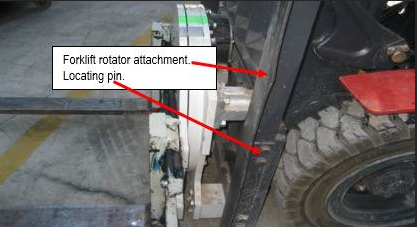

Rotating Attachment

S A SWMS must be developed for rotating attachments or incorporated into a forklift operations SWMS and submitted to MPX for review.

Where rotating attachments are used on forklift / telescopic handlers, the tines must be appropriately secured to perform the task they are undertaking (i.e. will not disconnect when rotated)

Information must be provided on the data plates in relation to the:

- SWL with the increased weight of the attachment

- Change to load centre of gravity with the attachment.

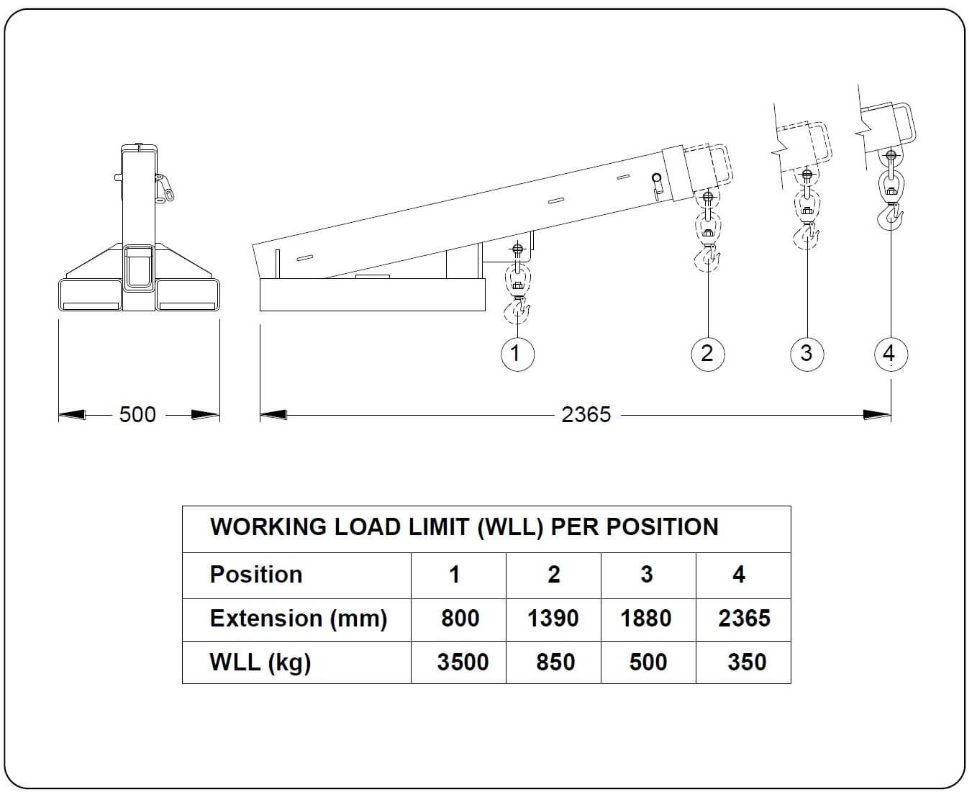

Jib / Hook

Where forklifts / telescopic handlers are configured to be used as a crane:

- S SWMS must be developed and implemented

- Jib attachment must be fitted with a data plate displaying the SWL and load chart

- The jib attachment must be secured with a safety chain or pins positively engaged

- Rated lifting equipment to be used, inspected and maintained in accordance with manufacturers specifications and Section: Plant and Equipment Inspection Schedule

- Dogmen must sling and direct the load

- Chain blocks connected to the jib must have a current inspection tag attached to the chain block which must have a safety latch

- Lifting equipment used must be in accordance with Section: Lifting Equipment

- R Operator training / competency to be in accordance with Training and Competency Schedule.

Work Platform

Telescopic handler configured with work platform, refer to:

- Section: Mobile Elevated Work Platforms.

Legal and Other Requirements

- AS 1418.19 Cranes, hoists, winches telescopic handlers

- AS 2550.19 Cranes, hoists, winches safe use telescopic handlers

- Managing Risks of Plant Code of Practice (Qld) 2013

Document Control

Version 1 August 2019 – New Standard