Scaffolding

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Design and Planning

Prior to the erection of scaffolding consideration should be given to:

- The intended use of the scaffold and its duty

- The stability of ground - where applicable a Qualified Person (geotechnical engineer) should be engaged by MPX to assess the ground conditions to evaluate that it is suitable to support the scaffold

- The protection at vehicular entry points e.g. with concrete barriers

- The protection from mobile plant movement/impact

E The total loads of a scaffold on a suspended concrete/timber slab should be verified and approved by a Qualified Person (structural engineer) to verify the structural capacity of the supporting structure. A scaffold is broadly subjected to two load conditions in service:

- Dead load is the self-weight of the scaffold and all scaffolding components used on the scaffold. For example, platforms, stairways, ladders, screens, sheeting, platform brackets, suspension ropes, secondary ropes, traversing ropes, tie assemblies or scaffolding hoists.

- Live load is the combined load resulting from the weight of all people, materials, and equipment on the scaffold plus any environmental actions e.g. wind.

The loads of a scaffold on the ground should be confirmed by the scaffolder to verify the capacity of the supporting foundations

Scaffolding should be designed in accordance with the requirements of AS/NZS 1576.

R Prefabricated scaffolding systems require Regulatory Authority design registration

R Scaffold plans must be certified by a Qualified Person (engineer) for complex scaffolds over 4 metres or as identified in risk assessment / planning and include where applicable:

- Type of scaffold , the system and/or component manufacturer used

- Bracing requirements

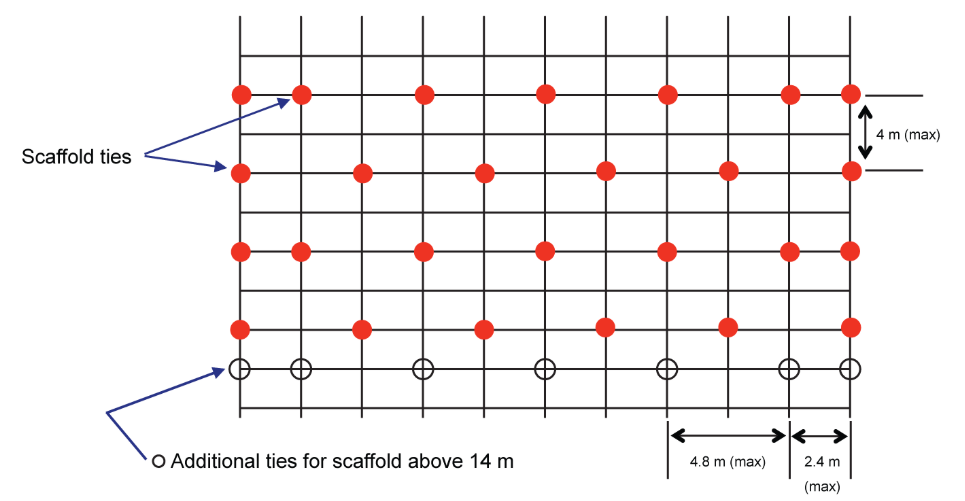

- Types of anchors (Ties, cast ins and fixings location, spacing and details)

- Location and number of live working decks available at any one time

- Access ways, access stairs, stretcher stairs and entry & exits locations taking into account the finished floor level (FFL) of the structure

- Internal intermediate, handrail ledgers and kick boards

- Staging of scaffold movements( Hop ups, platforms, hoists and rubbish chutes

- Duty / Rated capacity (e.g. Light, Medium or Heavy duty, Special)

- Details relating to staggering for standards

- Foundations requirements

- Clearances to structures

- Containment sheeting (if used)

- Minimum distances to proximity hazards (power lines, in-ground services, public, operational plant)

R Scaffold plans should have sufficient detail so that the erected scaffold can be verified by a Competent Person (licensed scaffolder) to the design at any stage.

- A Scaffold plan could be a plan illustrating a Qualified Person (Engineer) design or a manufacturer's design drawing e.g. for a mobile scaffold.

R NSW - Complex scaffolds must have a third-party Qualified Person (Engineer) who was not engaged in the original design to assess the design for its intended use

R NSW - Complex scaffolds must have a third-party Competent Person (licensed scaffolder) verify that the erected scaffold conforms to the design prior to use

Notes: Complex scaffolds include but not limited to:

- Perimeter scaffold

- Suspended scaffolds (e.g hung scaffold or cantilevered)

- Birdcage scaffold

- Spur scaffold

- Scaffolds used as falsework (Refer to Formwork)

- Scaffolds designed to be lifted by a crane

- Scaffold loading bays

- Where different prefabricated scaffold systems or components are mixed

- Scaffolds erected over public vehicular or pedestrian traffic (i.e. a Gantry)

- Scaffolds that exceed parameters specified by the original system manufacturer (e.g. extra height)

- NSW - Scaffolds with significant non-uniformity e.g., numerous changes in lift height and bay width

- QLD - Tube and coupler scaffold greater than 33 m TWP or outside of scope of AS/NZS 1576.6

- QLD - Bridging beams, truss or ladder beams (greater than 4.8m span or 6m of scaffold above)

- QLD - Independent free standing or guyed scaffold towers – greater than 4 m TWP (including aluminium static or mobile tower more than 9m TWP)

- QLD - Stair tower – independent or attached (more than 20 m high)

- QLD - Perimeter demolition scaffold (more than 9 m high)

Changes to the design of the complex scaffolding system or scaffolds identified in risk assessment / planning must be authorised and signed off by a Qualified Person (engineer).

E - Needles on suspended scaffold should be clearly shown on a detailed drawing and the structural adequacy verified by a Qualified Person (Structural Engineer).

Operational

R All scaffolds must be constructed, altered, repaired and dismantled by a Competent Person (licensed scaffolder, refer to Training and Competency Schedule

- WA Scaffolds 2 metres or higher

- NSW, VIC, QLD Where there is a potential to fall 4 metres or more

Scaffolds <2 metres (WA) or <4 metres (NSW, VIC, QLD) must be constructed, altered and dismantled by a Competent Person who is trained/familiar with the instructions of the scaffold system

R NSW - A safety/scaffold management plan for all complex scaffolds is required to be submitted by the scaffolder to Multiplex for review and should consider:

- Method of consulting workers and other subcontractors, such as prestart, toolbox meetings.

- Management for the prevention of overloading scaffolds

- Management for the prevention of tie removal, edge protection, hop-ups, and other decking components

- Method to ensure only appropriately qualified and authorised personnel modify scaffolding

- Monitoring program

- Method for workers to report issues or request scaffold modifications

- Method to ensure that workers are prevented from accessing closed scaffolds

S A task-specific SWMS is required for scaffolding activities (erection, modification, dismantling), SWMS’s must be submitted to MPX for review prior to scaffolding activities.

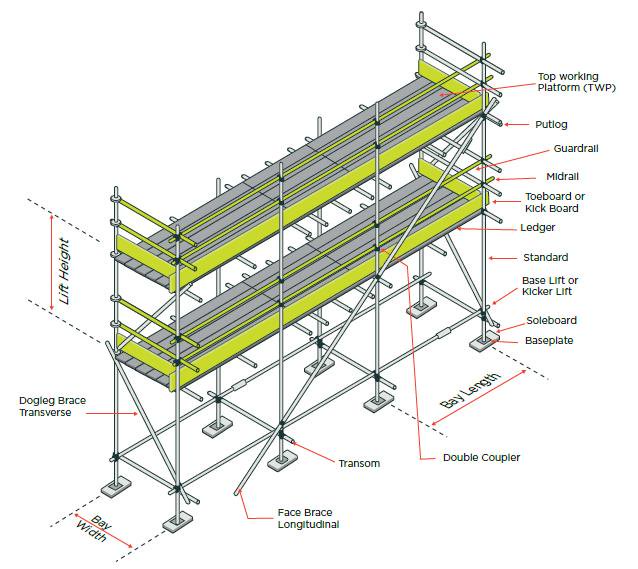

Scaffolds must be constructed in accordance with the manufactures specification, constructed with all appropriate components in place (ledgers, transoms, braces, ties etc.).

All platforms and landings must have edge protection fitted to all open edges at or above 2 metres consisting of a top rail, mid rail and toe board or top rail and mesh panel.

Scaffolding must be erected and dismantled in compliance with AS/NZS 1576.1 and AS 4576.

A clear area for storing scaffolding components must be provided: scaffolders must stack components in stillage’s and fittings in storage boxes.

Incomplete scaffolds must have ‘Scaffold Incomplete – Do Not Use’ signage fitted at main points of access/egress onto/off the scaffold.

Scaffolds must not be used if incomplete.

Completed scaffolds 2 metres or higher must have attached at access points, a durable tag indicating the specified duty, erector, date of erection and inspection date as per AS4576.

R Scaffolds over 4 metres must have a handover certificate and be inspected regularly, following installation prior to use, at least every 30 days or after any alteration, repair, or inclement weather and after an incident affecting the scaffold. Refer to:

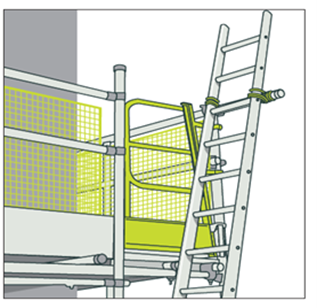

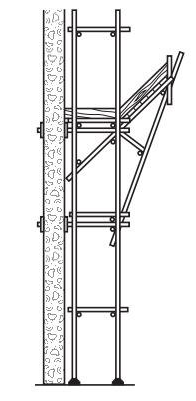

Access shall be provided to each working platform of the scaffold by either ladders or stairs. Where practical ladders should be internal.

Where internal ladders are

used a trapdoor is required to be installed over the opening. Where external ladders are used, access to working deck shall be via self-closing gate.

Figure 2: Example of a typical ladder access with a hinged trap door

Figure 3: Example of a typical external ladder access with a self-closing safety gate

An external perimeter scaffold with a top working platform more than 8m high (generally four lifts from the lowest ledger position) and a length of more than 60 metres, should be provided with at least two means of access and egress, one of which should be suitable for emergency stretcher access. This does not include detached dwellings.

Figure 4: Example of stretcher stairs

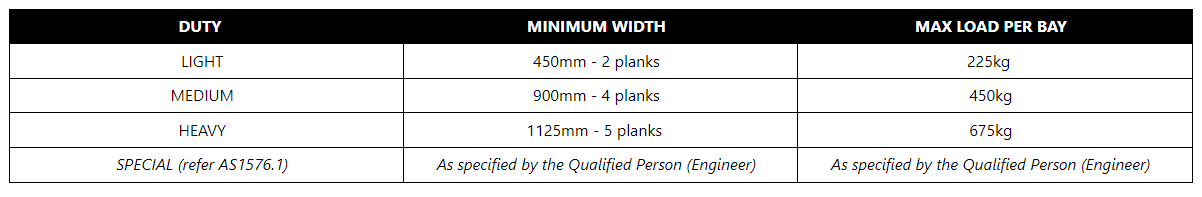

All working platforms must be of a suitable width for its intended duty but not less than 450mm wide, must be fully planked with planks/boards secured to prevent up lift or movement.

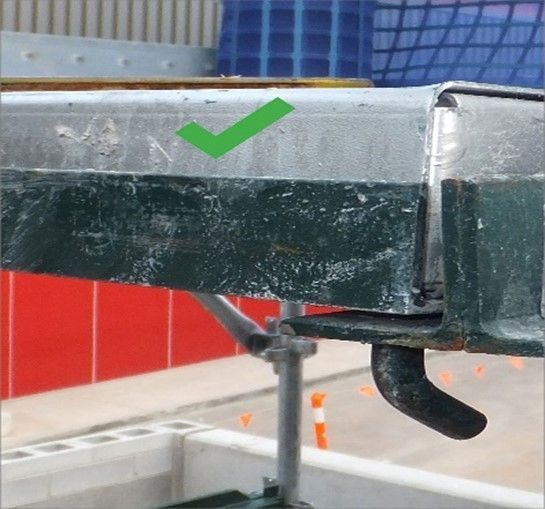

End bay platform (hop-up) brackets should be:

- Installed with tie bars as per the manufacturer’s instructions i.e. for certain prefabricated systems, this would be those that have a cranked pin angled inwards (towards the scaffold) and the lip of the tie bar facing inward or outward (away from the scaffold) as per manufacturer’s instructions. Refer below examples.

Photo 2: Example of a cranked pin angled inwards (towards the scaffold) and the lip of the tie bar facing inward

Photo 3: Example of a cranked pin angled inwards (towards the scaffold) and the lip of the tie bar facing outward

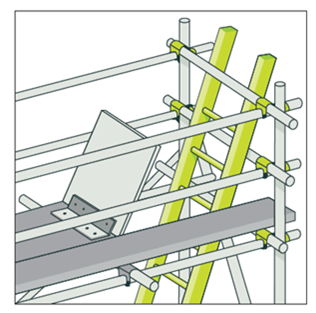

Alternatively, (as per the manufacturer’s instructions i.e. for certain prefabricated systems), end bay platform (hop-up) brackets could also be installed with a secondary restraint eg. restraint tube. Refer example below

Photo 1: Example of a restraint tube being installed at a platform end bay

Components (except for baseplates, soleplates, timber of known grade and plain tube that is not of a prefabricated component) must be compatible and marked with a symbol or letters to identify the scaffold manufacturer or supplier and, as appropriate, the system type.

Scaffold must be erected no more than 225 mm from the building structure where the face is a working face.

Scaffold must be erected no more than 100mm from the building structure where the face is not a working face.

If scaffold is erected more than 225mm from the building structure, edge protection including a toe board is required

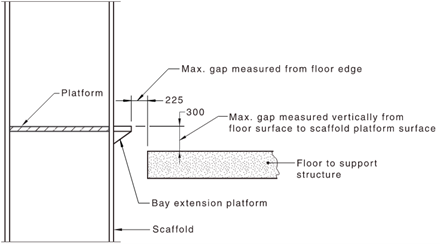

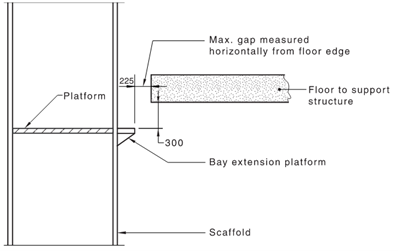

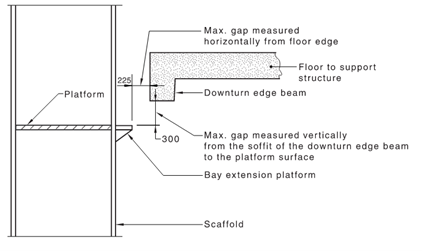

Edge protection or components of edge protection may be omitted from a platform or landing adjacent to the floor of a building or structure, provided

Where the floor is adjacent to a working face - the floor is not >225mm horizontally from the platform edge

Where the floor is not adjacent to a working face – the floor is not >100mm horizontally from the platform edge.

The upper surface floor is not >300mm vertically below the surface of the platform edge

The soffit of the floor (or dropdown beam) is not >300mm vertically above the surface of the platform edge

Figure 7: Platform surface – Higher than floor of adjacent structure (extract from AS1576.1 - Figure 3.10.4.2(A))

Figure 8: Platform surface (flat floor edge) – Lower than floor of adjacent structure

(extract from AS1576.1 - Figure 3.10.4.2(B))

Figure 9: Platform surface (downturn beam at edge) – Lower than floor of adjacent structure (extract from AS1576.1 - Figure 3.10.4.2(B))

Where there is a risk of fall, then fall protection must always be used when installing, altering, repairing and dismantling scaffolds.

Exclusion zones must be established while the scaffold is being erected, altered, repaired or dismantled.

Clearances between scaffold and any transmission line must be in accordance with

A scaffold must not be loaded beyond its specified duty.

Figure 10 Common scaffold terms and components (Source: WorkSafe NZ). Note: access and building/structure ties omitted for clarity

Containment Sheeting

Containment sheeting is fitted to scaffold as a means of protecting persons (including the public) against a risk of falling objects and/or containing dust from works performed (i.e. demolition).

Containment sheeting must be in accordance with AS 4576 (section 8.10).

Where a containment sheeting is to be fitted to scaffold, the Qualified Person (engineer) must take into account the wind loading (i.e. ‘live load’) of such containment sheeting and refer to manufacturer for fixing requirements (of the containment sheeting).

Containment sheeting must be:

- Attached to the outside of the scaffold unless otherwise specified by the Qualified Person (Engineer)

- Continuous, by using sufficient overlap

- R Be verified as flame retardant (refer to AS1576.7 and AS/NZS1530.3)

- R Periodically inspected and maintained.

- Labelled

Scaffold used in demolition work

Scaffold used in demolition work, must:

- Be heavy duty rated

- Be erected to the full height of the structure

- Have a closely board platform with a minimum width of 1 metre that abuts on the face of the structure at the working level

- Have a fender board not less than 900mm high fitted on the outer edge and on the ends of the working platform

- Have the external face and ends sheathed with a fire-retardant material and wire mesh that has wires that are at least 3mm in diameter and with apertures not greater than 50mm x 50mm

- Be maintained in position and in an effective state up to the working level of the scaffold for the whole of the period during which the demolition work is being carried out; and

- Be progressively dismantled so that the unsupported part of the scaffold does not exceed by more than 4 metres the height of the last row of ties that secure the scaffold to the structure

Mobile Scaffolds

AS PER SCAFFOLDING and the following.

Mobile scaffolds must:

- Be assembled and dismantled as per the manufacturers/suppliers instructions

- WA Be assembled and dismantled by a scaffolder when erected next to the edge of a void irrespective of height or building when > 2 m in height

- NSW, VIC and QLD Be assembled and dismantled by a scaffolder when erected next to the edge of a void or building when > 4 m in height

- Have castors that comply with AS 1576.2 and be locked when the mobile scaffold is in use or unattended

- Not be moved with people on the work platform

- Have outriggers fitted when the working deck is three (3) times the minimum width of the scaffold or 6 metres high

- Be set – up on a stable and level surface

- Have an internal ladder access that and trap door provided where the working platform is higher than 2 metres.

All items (tools, equipment etc.) must be secured prior to relocating the mobile scaffold.

Mobile scaffold should not be located closer than 1 metre to any unprotected edge, change in level, or penetration unless it is secured to a structure, compliant guard edge protection or similar to prevent it moving, and all castors must be locked.

Trestle Scaffolds

Operational

- AS PER SCAFFOLDING – GENERAL, and the following:

- Must be assembled as per the manufacturers/suppliers instructions.

- Are restricted to single lift configurations <2 m.

- Must have edge protection consisting of a top/hand rail as a minimum.

- WA - Are only to be built or altered by workers who hold as a minimum, a Basic Scaffolding (SB) HRWL.

Spur Scaffolds / Catch Fans

Informative - A spur scaffold is a scaffold or portions of a scaffold supported by inclined load bearing members connected directly or indirectly to supporting standards

Spur scaffold/catch fans must:

- Be designed by a Qualified Person (scaffold engineer)

- Be installed and inspected by a intermediate of advance scaffolder, refer to:

- Plant and Equipment Inspection Schedule

- R Have a handover certificate issued to verify that the scaffold has been erected / altered by a licensed scaffolder and is ready for use

- Be of robust construction and designed to withstand the maximum potential impact load

- Incorporate a fully planked-out deck

- Be positioned so the deck extends at least 2m beyond any unprotected edges of the work area except where extended guard railing is fitted to the catch platform

- Be positioned as close as possible to the underside of the work area – the distance a person could fall before landing on the catch platform should be no more than 1m

- Always be used with compliant edge protection.

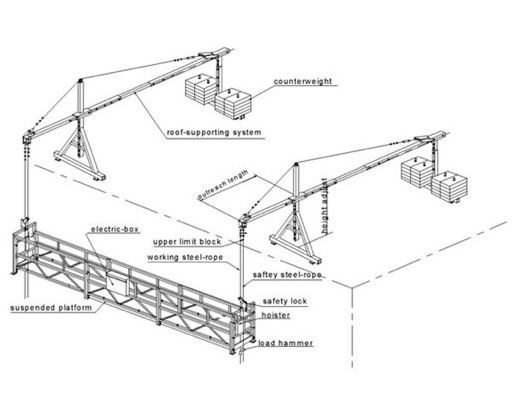

Suspended Scaffolds (Swinging Stages)

Informative

Suspended scaffolding is where the platform can be raised and lowered and is generally hung from temporary overhead supports by flexible steel wire ropes running through scaffolding hoists.

Design and Planning

E Design certification (including installation design) must be provided by the supplier.

Suspended scaffolds must be supplied and fitted with:

- A twin rope system

- An RCD protected power outlet

- A legible data plate bearing the following information

- Type model identification, serial number and name or identification mark of the manufacturer

- Details of steel wire rope used

- Rated capacity hoisting

- Reeving requirements (where applicable)

- Power supply requirements (where applicable)

- Labelled and operational functions displayed. Switches should be of the spring loaded ‘deadman’ or ‘hold to run’ type. Labels should include operating instructions, emergency stop switch, up and down controls

- A loadlimiting device that will prevent the hoist from lifting more than 125% of its rated load

- A secondary protective device that is capable of stopping the cradle from falling if the hoist fails.

Cradle must be supplied and fitted with:

- Guardrails, midrails, mesh panels and toe boards with no visible signs of mechanical damage

- Nonslip working deck with adequate drainage holes with visible signs of mechanical damage

- Fire extinguisher

- Emergency contact details displayed

- Safe working load (in Kgs) displayed

R The supplier must induct all workers that are going to operate the suspended scaffold.

R The supplier must provide written operating / safe use instructions, emergency procedures and a logbook or similar for daily safety prestart inspections (e.g. checklist).

Installation

S A task-specific SWMS is required for installation, maintenance and removal of suspended scaffolds, SWMS’s must be submitted to MPX for review prior to the installation, maintenance or removal.

Be installed and inspected by an advanced scaffolder, refer to:

S Supporting structures must be assessed by a Qualified Person prior to erection.

E Installation of the suspended scaffold must be certified prior to use and after any alteration

- Inclusive of suspension scaffold system, needle suspension system, wire rope, cradle and hoist, refer to:

- Plant and Equipment Inspection Schedule

Needles and supporting beams and associated accessories (scaffolding tube and fittings, counterweights etc) must comply with appropriate standards and be designed for the intended load in regard to anchorage methods and stability factors.

Counterweights (when used) should be mounted to the suspension in a manner where they cannot be removed without using a tool.

Shackles, chains, slings etc should be secured and protected to prevent accidental displacement and damage.

Flexible steel wire ropes used for suspension must comply with the manufacturer’s recommendations, be compatible with the overall system and be protected to avoid kinking, fouling and other damage.

Consideration to restricting lateral movement of suspension rope should be given in structure design by way of incorporating vertical tensioned wire rope systems, lanyards, ties, suction units etc.

Anchorage points must be verified by a Competent Person, refer to:

The main power supply should be locked or secured in an area to avoid unauthorised or unintentional interference.

R VIC - The Swing Stage Inspection Checklist must be completed.

Operational

S People carrying out work (installation, maintenance or removal) or operating a suspended scaffold must be inducted (by the supplier) into the applicable operating and rescue procedures, SWMS and hold valid records of competency / training , evidence must be retained on site, refer to:

Overhead and proximity hazards (e.g. power-lines, building structures, trees) must be assessed prior to use of the suspended scaffold. Exclusion zone / clearance from these hazards must be maintained.

The suspended scaffold operator and any occupants must wear a fall injury prevention device.

Safe access/egress must be provided to the suspended platform.

Lanyards must be fitted to all tools and equipment and securely connected to the suspended platform.

Suitable exclusion zones must be established below and above the suspended scaffold.

The SWL of the suspended scaffold must not be exceeded, taking into account the weight of the operator, any other occupants and materials.

Personnel and materials must be securely confined within the suspended platform, unless the suspended scaffold is specifically designed to carry materials outside (e.g. jib attachment).

The suspended scaffold must only be operated in favourable weather conditions. Where conditions become unfavourable (e.g. strong wind, lightning), the operator must return to the suspended scaffold to the storage position.

An effective method of communication between occupants of the suspended scaffold and the ground must be established (e.g. two-way radio or mobile phone).

S Emergency and rescue procedures must be in place and be reviewed prior to operation and should identify nominated, trained, site-based personnel who would be available to lower the cradle should the operator experience difficulties.

During breaks, the platform must be secured to the structure and the power disconnected from the scaffold hoists or supply point.

For overnight or longer periods, the platform must be parked in its storage position, secured to the structure (where applicable) and the power disconnected.

Documents and Forms

Australia

- Information tag

- Manufacturer’s instructions

- Prestart / daily inspection logbook

- Scaffold plan/handover /safe for use certificate (where applicable)

- SWMS

- Swing stage – design certification

Victoria

- Swing Stage Inspection Checklist - Form 012

Queensland

- Scaffold Inspection Checklist

Legal and Other Requirements

- Scaffolding Code of Practice (WorkSafe QLD)

- Scaffolding Industry Standard (SafeWork NSW)

- Scaffolding Code of Practice (WorkSafe VIC)

- General Guide for Scaffolds (SafeWork Australia)

- AS4576: Guidelines for scaffolding

- AS/NZS1530.3 Combustibility Tests for Materials

- AS1576.1 Scaffolding - General requirements

- AS1576.7 Scaffolding - Safe use of encapsulation on scaffolding

Document Control

Version 1 August 2019 – New Standard

Version 2 December 2020 - Additional clarification of when a scaffold plan is required along with any changes

Version 3 June 2021 - Access shall be provided to each work level of the scaffold by either an internal ladder or stair, as far as practical the ladder or stair is required to be internal.

Version 4 November 2023 – Additional requirements have been incorporated covering various areas, including defining complex scaffolds, mandating safety and scaffold management plans in NSW, specific procedures for erecting end bay platforms (hop-up brackets) as a response to an incident in NSW, scaffold requirements during demolition, third-party reviews for design and installation in NSW, and elaborated scaffold erection procedures.