Concrete Placement Equipment (Line, Mobile or Satellite)

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Note: This section is to be read in conjunction with:

- Section: Plant and Equipment - General

- Section: Placement - Concrete

Informative

Plant & Equipment used in concrete pumping includes the following:

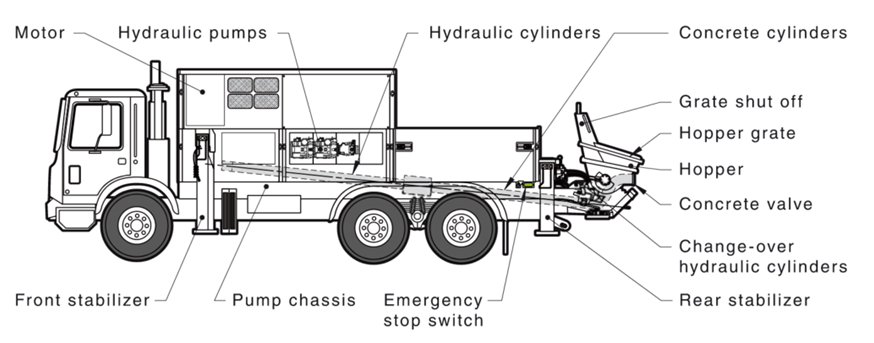

- Line Pump: A type of concrete placing equipment described as a line pump, skid, vehicle or trailer mounted pump without a boom. This type of pump requires steel pipes or flexible placing hose(s) to be manually attached to the outlet of the pump. Pipes/hoses are linked together and are positioned manually or connected to a satellite placing boom.

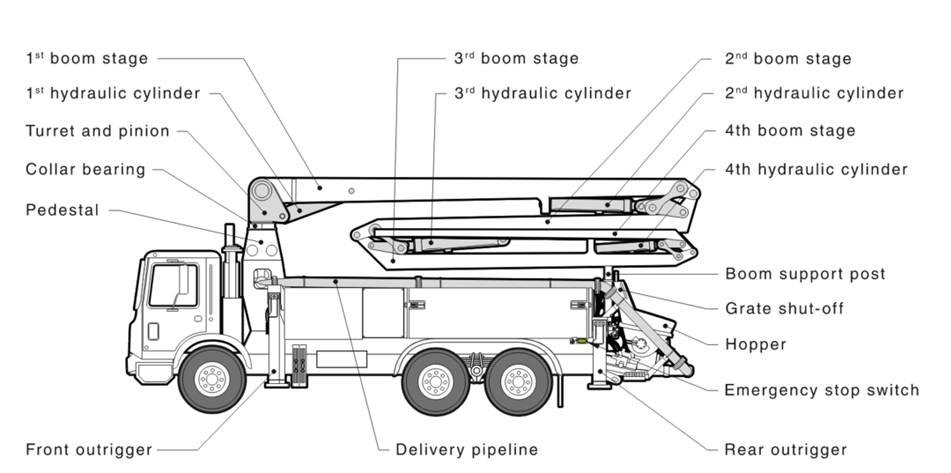

- Mobile Placing Boom: A type of concrete placing equipment which is described as a mobile boom pump mounted on a vehicle. This type of pump incorporates an articulating knuckle boom, capable of power operated slewing and luffing (raising/lowering) to place concrete by way of pumping through a pipeline attached to, or forming part of, the boom of the plant.

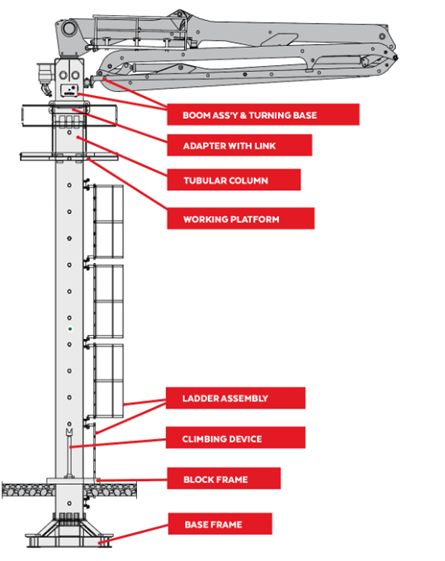

- Satellite Placing Boom: A type of concrete placing equipment, which is described as a tower, pedestal, column, mat, satellite, gravity, remote or separate placing boom mounted onto a fixed or mobile carrier. This type of boom incorporates an articulating knuckle boom, capable of power operated slewing (or rotary distributor manually maneuvered) and luffing (raising/lowering) to place concrete by way of pumping through a pipeline attached to, or forming part of, the boom.

Hazards

Potential hazards include, but are not limited to:

- Collapse incl. structure, ground, boom pump, etc)

- Pipe/coupling failure

- Structural boom failure

- Uncontrolled discharge

- Proximity hazards.

- Hose whip

- Noise / Fumes

- Wind

- Contact / collision with mobile plant or equipment

- Manual handling

- Compressed Air

- Environmental impact (e.g., uncontrolled discharge of concrete aggregate)

Planning

Proximity hazards must be identified prior to set-up and assembly including:

- Overhead / adjacent structures

- Excavations, pits, tanks, soak wells

- Public

- Overhead Services (power lines) and other electrical equipment

- In-ground services

- Other mobile or fixed plant including other plant sharing air space e.g., mobile cranes, tower cranes, hoists

- Overhead works

Where planning to use concrete pumps, consideration must be given to site logistics and public safety, including:

- The setup location for concrete pumps and associated plant or equipment

- Public safety (e.g., vehicles and pedestrians) including exclusion areas / protective screens / covered walkways or barriers

- Traffic management / controls including the use of spotters for reversing concrete delivery trucks (Ref to Section: Traffic Management)

- Defined delivery access routes for concrete delivery trucks

- Safe working distances when adjacent to overhead powerlines (Refer to Section: Approaches and Clearances around Electrical Assets)

Planning – Line Pumps / Mobile Placing Boom

E

Ground bearing pressure for intended loads from truck / outriggers (including setup on suspended slabs) and suitability of set-up location must be confirmed prior to set-up and be in accordance with engineer’s report / specifications and where required any authority approval/ requirement,

Planning – Satellite Placing Boom

E

A satellite placing boom design and staging must be completed by a Qualified Person.

E A Competent Person must supervise the assembly and installation of a satellite placing boom, verify the assembly is in accordance with the manufacturers specifications and provide handover documentation.

Operational

S A task-specific SWMS is required for concrete pumping activities; SWMS’s must be submitted to MPX for review prior to concrete pumping activities commencing on site.

R People carrying out concrete pumping work must be inducted into applicable SWMS and hold valid records of competency / training, evidence must be retained on site, refer to:

Concrete delivery trucks should have clear and safe access to / egress approach from the concrete pump hopper.

- Where concrete deliveries are expected to reverse onto the receiving hopper on an external/public road, a traffic controller must be present to direct traffic to prevent interaction of concrete delivery trucks and public vehicles/members of the public

- Where concrete deliveries are expected to reverse onto the receiving hopper within the project boundaries a spotter must be present to direct the movement of delivery trucks.

Traffic controllers / spotters and any truck driver discharging at the pump should be in positions which prevent them from being caught between the hopper and a reversing truck (e.g., out of “line of fire”).

R Concrete line pumps and concrete placing booms (mobile and satellite) must be inspected and maintained as per the manufacturer’s specifications and applicable regulatory requirements– refer to:

R Concrete pumps and concrete placing booms (mobile and satellite) must be inspected and registered on site prior to use on site and in accordance with MPX Procedures - refer to

- Section: Plant and Equipment – General

Pipes and Clamps

R

Concrete pipe thickness testing (incl. bends and reducers) for line pumps, mobile placing boom and satellite placing booms must be conducted at frequencies in accordance with AS 1418.15 Cranes, Hoists and Winches – Concrete Placing Equipment. Refer to

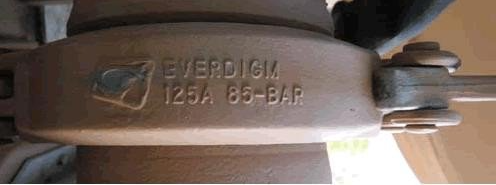

Pipe clamps used on any pipeline system must be:

- Permanently marked with the manufacturer's name (or trademark) and the maximum permissible operating pressure in bar (BAR) or pressure nominal (PN)

- Visually inspected by a Competent Person for signs of wear or damage before each use.

- Where observed to be damaged be replaced before use.

- Rated at a higher working pressure than the maximum working pressure of the concrete pump.

Quick release clamps must be fitted with locking pins (R-Clips) to prevent inadvertent release.

Pipe clamps that have worn pins, cracks, deformations or any other signs of excessive wear must not be used.

Individual components of a pipeline system must be compatible and comply with the pump manufacturer’s specifications.

A pipeline must be installed as per AS 2550.15, verifying that:

- Horizontal and vertical pipelines are adequately supported, where directional change occurs, be fixed in accordance with manufacturer instructions, typically at either side (e.g., each side of a 90-degree bend)

- Flexible hoses are not at risk of mechanical damage e.g., from plant / equipment

- Each pipe segments should be clearly numbered with a permanently fixed unique identification mark or number, prior to being placed in service.

Note: Cranes or hoist towers, scaffolding or formwork should not be used to support/secure the pipeline unless specifically designed for purpose of supporting concrete distribution pipelines, where used support must be installed in accordance with the design.

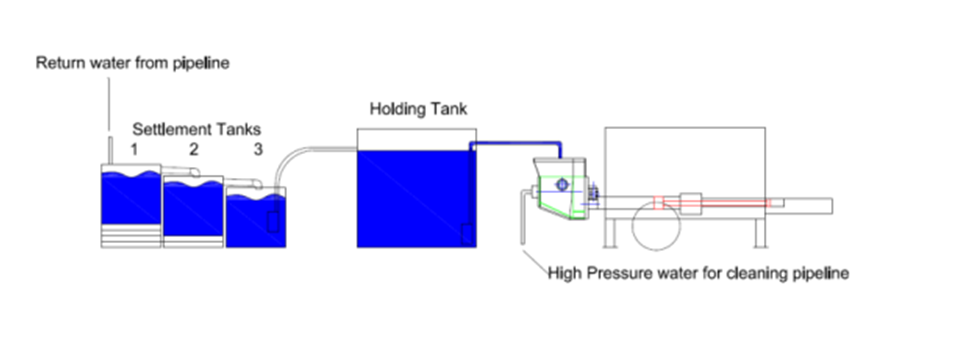

Cleaning out / Blowing Out concrete pumping equipment and trucks

Cleaning out concrete from pumping equipment (e.g., pumps, pipelines etc.) must only be carried out by Competent Persons and in accordance with the manufacturer’s procedures or suppliers/subcontractors SWMS

Where practicable concrete trucks should be taken back to the off-site batching plants to be cleaned out.

Where concrete trucks or concrete pumping equipment is required to be cleaned on site, cleaning out must be in designated areas, concrete must be collected / retained in bins or plastic lined trenches or similar and not be washed out onto open ground / stormwater drains, etc.

Where cleaning of static concrete pipelines is undertaken using water:

S Task specific SWMS or SOP is required

- Exclusion area is to be established to restrict unauthorised access

Where cleaning of static concrete pipelines is undertaken using compressed air into a concrete waste bin or a concrete truck agitator:

S Task specific SWMS or SOP is required

- Exclusion area is to be established to restrict unauthorised access

- Rubber hose/s are to be removed from the pipeline

- Blowback pipe is to extend 600mm beyond the concrete truck barrel drip ring or a-frame through the fins

- Appropriate work platforms are to be provided for a worker to fit the blowback pipeline

- A pressure relief valve must be to allow for depressurisation i.e. before removing any pipeline

Operational - Mobile Placing Boom

P Prior to setting up a mobile placing boom the following must be implemented:

- WA – Permit to Work - Outrigger / Mobile Crane / Piling Rig

- NSW / QLD - Mobile Plant Outrigger Set-up Permit

- VIC / QLD - Mobile Concrete Pump Checklist for the initial setup

Concrete pumps should not be operated unless the opening of the hopper is fitted with a safety grille / guard:

Mobile placing booms must not be left unattended while in operation

Exclusion zones (e.g., barricading and signage), protective screens, or barriers must be established around the mobile placing booms and concrete line.

Grilles must:

- Be constructed of parallel or mesh bars

- Require a tool to be removed, or

- Connected to an interlocked cut-out switch designed to stop all moving parts if the grille is lifted

Workers are not permitted to stand on the grille

Operational – Satellite Placing Boom

- Satellite placing booms must not be left unattended while in operation

- Records of worker training / instruction (for climbing / sections being added / removed) must be available for the specific make / model of satellite placing boom.

R NSW - Where climbed / sections are added, and a handover certificate must be provided to MPX prior to use.

R All electrical connection points/sockets including the head control box (located on the crow’s nest) of the satellite placing boom must be inspected, tested and tagged as a minimum every 3 months.

Concrete - Kibbles

- Refer to Section: Lifting Equipment

Legal and Other Requirements

- AS 2550.15 Cranes, Hoists & Winches – Safe Use – Concrete placing equipment

- Concrete Pumping Code of Practice (Qld)

- WorkSafe Victoria Concrete Pumping Industry Standard

- Safe Work Australia Guide to managing risk in construction: Concrete pumping

- CCAA Guideline Water Wash Out or Blow Back

- CCAA Concrete Pump Delivery Industry Guidelines

Document Control

Version 1 August 2019 – New Standard

Version 2 July 2022 – Inclusion of the requirements for

- Site logistics and public safety

- Design, staging and assembly of a satellite placing boom

- Exclusion zones (e.g., barricading and signage), protective screens, or barriers around the mobile placing booms and concrete line.

- Cleaning out /blowing out concrete pumping equipment and trucks

- Training for climbing / sections being added / removed