Industrial Rope Access Systems

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Note: This section is to be read in conjunction with:

- Section: Work at Heights General

Definitions

- AARA - Australian Rope Access Association

- IRATA - International Rope Access Trade Association

Design and Planning

Where rope access work is planned to be carried out the following must be verified:

- E Anchorage points are fit for purpose, i.e. a Qualified Person (engineer) has verified the designed the anchorage system is certified as an anchorage system

- S Task-specific SWMS and emergency procedures have been developed and submitted to MPX for review

- Appropriate communication systems are established between rope access technicians

- R People carrying out rope access work hold valid records of competency / training and records maintained on site, refer to:

- Training and Competency Schedule

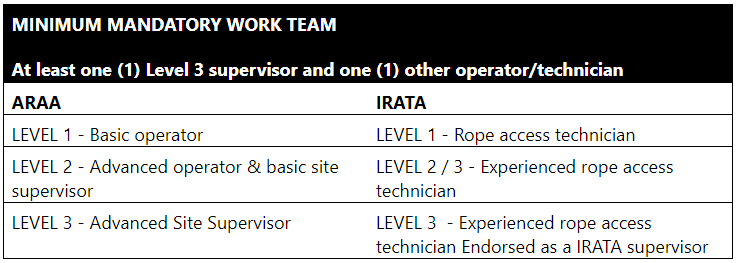

- The number of rope access technicians performing the work will be in accordance with AARA / IRATA standards, refer to Table 1

- The work will be supervised by Level 3 ARAA / IRATA qualified rope access technicians

TABLE 1: MINIMUM WORK CREWS

Operational

R Rope access equipment must be inspected prior to each use and at intervals in accordance with the IRATA or ARAA code of practice. Refer to:

Rope access equipment must be maintained and correctly stored.

Employees must wear safety harnesses suitable for rope access work and they are trained appropriately, refer to:

- Section: Fall Injury Prevention Systems

Fit for purpose safety helmets (with chin straps) must be used.

Lanyards must be fitted to all tools/equipment

Safe access must be provided for rope access technicians to commence abseiling.

Suitable exclusion zones must be established below the rope access technicians and around their rigged rope access equipment.

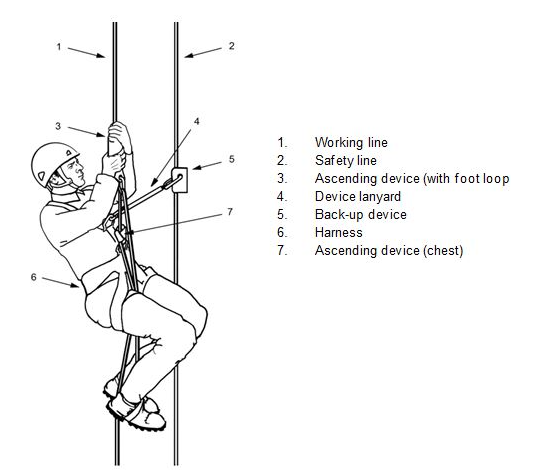

Rope access rigging must incorporate at least one additional means of protection to prevent a rope access technician falling (e.g. a safety line).

Rope access technicians must be connected to both the working line and the safety line via a harness.

Legal and Other Requirements

- CP - IRATA or ARAA

- AS/NZS 1891.1 Industrial fall-arrest systems and devices – Harnesses and ancillary equipment

- AS/NZS 1891.2 Industrial fall-arrest systems and devices – Horizontal lifelines and rail systems

- AS/NZS 1891.3 Industrial fall-arrest systems and devices – Fall-arrest devices

- AS 1891.4 Industrial Fall Arrest Systems

- AS 1891.4 Industrial Fall Arrest Systems and Devices - Selection Use and Maintenance

- AS 4488 industrial rope access system specifications

- AS/NZS 4488.2 Industrial rope access systems – Selection, use and maintenance

- Managing the risk of falls at workplaces Code of Practice (Qld) 2018

Document Control

Version 1 August 2019 – New Standard