Asbestos Containing Materials in Buildings/Structures

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Note: This section is to be read in conjunction with Asbestos Containing Materials (ACM) - General

Risk Assessment

Based on available information (refer above), identified ACM for removal or management must be assessed in terms of risk, taking into account:

- The location of the ACM in relation to site activities

- The risk of disturbing the ACM if present, and

- The condition of the ACM (i.e. friable or nonfriable).

Based on this assessment, the following must be developed:

- R An asbestos register

- R An Asbestos Removal Control Plan (ARCP)

- R Safe work methodologies for any ACM disturbance, removal and disposal activities

- Safe work method statement, and

- R Applicable monitoring or validation programs.

R Where the demolition of a building or part of a structure is planned, all ACM must be removed within that area and a clearance certificate issued by a Competent Person who specifies that the building or structure is clear of ACM.

Contractor Documentation

R Contractors engaged to undertake ACM removal and disposal activities must be licensed in accordance with regulatory requirements:

- Removal of friable ACM must only be undertaken by a contractor who holds an :

- WA Unrestricted asbestos license

- NSW, QLD, VIC – Class A license

- Removal of nonfriable ACM must only be undertaken by a contractor who holds an :

- WA Unrestricted asbestos license OR a restricted asbestos license

- NSW, QLD, VIC – Class A OR B license

- The licensed contractor’s employees must be formally trained in the identification, handling, removal and disposal of ACM

R Prior to commencement, where any quantity of friable ACM is removal is required, the licensed contractor must inform the regulator/statutory authority in accordance with jurisdictional requirements. The licenced supervisor should listed on the notification and be present at all times during the removal process.

- The jurisdictional notifications are as follows

- Victoria

- Queensland

- New South Wales

- Western Australia

R Asbestos Removal Control Plan (ARCP) (developed by the licensed contractor) for any licensed removal work should includs but is not limited to addressing the following areas:

- Identification

- Preparation

- Removal

- Decontamination

- Waste Disposal,

- Clearance Inspections and monitoring requirements

- S SWMS – detailing the planned handling, removal, disposal and decontamination methodology and other high risk activities

Note: A ARCP is not required for adhoc <10m2 non-friable asbestos

R Copies of the ACRP and SWMS along with records of employee review and sign-off must be available at the workplace during ACM removal activities.

R NSW - ACRP and SWMS must be reviewed by a Competent Person.

Health Monitoring

Verification of Personal Health Monitoring records must be obtained for each worker and maintained by the subcontractor and medical practitioners in accordance with regulatory requirements after the record is made. Records must be kept as confidential unless written consent is provided by the worker.

Establishing ACM Removal Boundaries

The boundaries of the ACM work area & ACM removal site should be determined by the Licensed Removalist in consultation with a Competent Person and MPX, based on a risk assessment & defined in the ARCP..

Responsibilities for the security and safety of the ACM removal boundaries should be specified in the ARCP.

ACM removal boundaries must be defined with:

- Barricading

- Signage

Tape may be used as a barrier to define an ACM work area for some types of ACM removal work of short duration

Personal Protective Equipment

All persons engaged in ACM work must wear respirators, coveralls, protective gloves, safety footwear etc. in accordance with their ARCP & SWMS.

Where practical, disposable protective clothing should be used. Where equipment is not disposable (e.g. some respirators & safety footwear), these must be decontaminated and maintained, refer to ‘Decontamination’.

Decontamination - Informative

Decontamination may be achieved by:

- Personal decontamination

- Decontamination enclosures

- Decontamination of equipment and tools

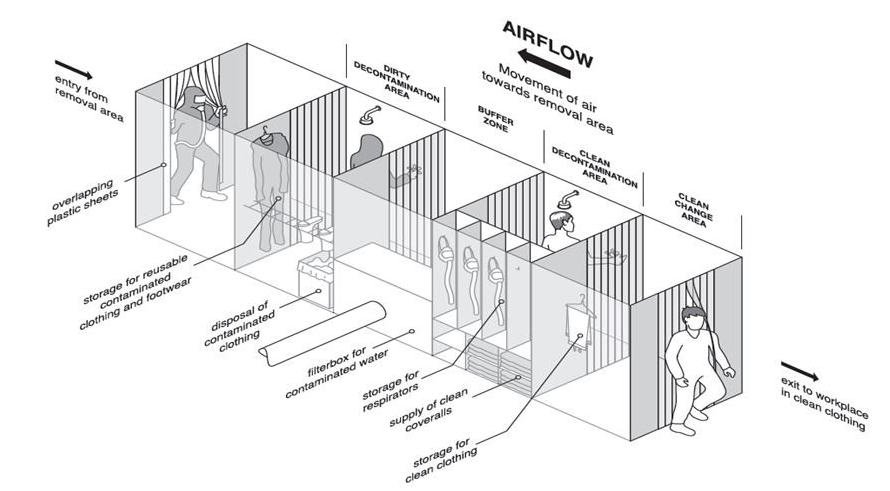

Personal Decontamination

Licenced asbestos removalists must provide an outline of their decontamination processes relevant to the works in their ARCP / SWMS. Personal Decontamination must be undertaken each time workers leave the ACM work area and at the completion of any ACM works. Personal decontamination must be done within the ACM work area where re-contamination cannot occur.

The decontamination method will depend upon whether friable or non-friable ACM is being removed:

If non-friable ACM is being removed, a Competent Person may conclude (based on a risk assessment) that a personal decontamination process is appropriate to manage the risk, as an alternative to a full wet decontamination unit (refer below), and

If friable ACM is being removed, or if extensive non-friable ACM is being removed, in many instances, a mobile or specially constructed on-site wet decontamination unit must be used. This decontamination unit should be immediately adjacent to, and directly connected with, the enclosed ACM work area.

The personal decontamination process and the use of a decontamination unit are further detailed in the Code of Practice for the Safe Removal of Asbestos 2nd edition [NOHSC:2002 (2005)].

Decontamination enclosures

Dry Decontamination enclosures should:

- Be constructed of heavyduty plastic sheeting and all the walls, windows and doors enclosed. Re-milled plastic sheeting should not be used.

- Where practical, have viewing panels placed in appropriate locations installed so that the asbestos removal work area can be seen from outside the enclosure.

- Have adequate lighting within the enclosure,

- Have floors protected with at least one layer of woven plastic to prevent penetration during the asbestos removal work. The joints should be lapped min 300 mm and sealed with doublesided tape and duct tape.

- Have an H type Vacuum to clean themselves of loose debris.

Additional requirements for wet decontamination units include:

- Hot shower facilities (in lieu of H type vacuum)

Additional requirements based on a risk assessment may include but not limited to the following:

- Full enclosure

- Air locks

- Negative pressure units which must:

- Be installed to prevent the escape of airborne asbestos fibres from an enclosed removal work area.

- Be installed to create a ‘negative’ air pressure of approximately 12 Pascall (water gauge) within the enclosed removal work area.

- Incorporate warning devices for filter integrity/overload and power failure.

- Incorporate a manometer or magnehelic gauge and an audible and visual alarm system which should be checked and recorded on a daily basis by either the Asbestos Assessor/Occupational Hygienist or the licensed contractor’s Supervisor.

- Ensure the air extracted passes through a HEPA filter to remove any asbestos before it is discharged to the outside.

Negative Pressure Units (NPU) and HEPA Vacuums must have:

- R A six monthly Dispersed Oil Particulate (DOP) test to ensure that there are no leaks in the HEPA filter or in the seals inside the NPU and HEPA vacuums.

- R An annual inspection performed consisting of, inspection of filters for damage, air tightness and proper function of the control mechanism.

- R An annual test or as frequently as outlined by the manufacturer on the appliance filtration efficiency.

A Competent Person must:

- Visually inspect and conduct a smoke test of the enclosure prior to commencement.

- Conduct daily visual inspections of the enclosure during asbestos works including the review of air monitoring results and negative pressure readings.

- Provide a clearance certificate for the area from which the enclosure was dismantled.

Decontamination of Equipment & Tools

All tools and equipment used during the removal task should be decontaminated using either wet or dry decontamination procedures

- Wet wiping preferred: Use damp rags to wipe down contaminated tools & equipment.

- Dry decontamination: Should only be used where wet methods are not suitable or pose a risk because of other hazards (e.g. electricity / water underfoot causing slipping). Vacuuming the contaminated tools & equipment with an ACM vacuum cleaner.

If tools and equipment cannot be decontaminated, or are planned to be reused at another ACM work area, they must be tagged to indicate ACM contamination and double bagged in ACM waste bags before being moved to the next ACM work area.

Disposal and ACM Waste Management

Avoid accumulating ACM waste within the ACM work area. If ACM waste cannot be disposed of immediately, it should be stored in a solid waste drum, bin or skip & sealed and secured upon the completion of each day’s work (eg. lid of the bin locked) or at the completion of ACM disposal activity such that unauthorised access is prevented.

Friable and non-friable ACM must be disposed of in appropriate waste receptacles.

NSW, QLD and VIC - ACM impacted soils and ACM (friable and non-friable) must be disposed of to a waste facility licensed under the Environmental Protection Authority (EPA) to accept ACM waste.

WA - ACM impacted soils and ACM (friable and non-friable) must be disposed of to a waste facility licensed to accept ACM waste, in accordance with the ‘Landfill Waste Classifications and Waste Definitions’ – classified as a Special Waste (Type 1).

R Records of ACM waste disposal must be kept for all quantities disposed and submitted to MPX.

R NSW - A copy of the EPA Waste Tracking document is required.

Monitoring and Clearance Inspections

A Competent Person must assess the requirements for clearance inspections, control monitoring and clearance monitoring prior to starting the works based upon the risk identified by the asbestos removal works.

A Competent Person must undertake clearance inspections which may include visual inspection, soil/dust/debris sampling, airborne fibre monitoring or a combination of them all.

A Competent Person must determine air monitoring requirements for friable or if there is a potential for non-friable to become friable, including but not limited to:

- The location and frequency of sampling

- Whether it is necessary to monitor air quality in areas adjacent to, above and below the ACM work area, taking into account the potential exposures to occupants of these areas and

- Whether additional routine air sampling is warranted in (for example) nearby highoccupancy areas.

Air monitoring must:

- R Have results reported as Fibres/ml and issued to MPX by the start of the next business day prior to the commencement of work in the area.

- R Have results available/printed at the sites.

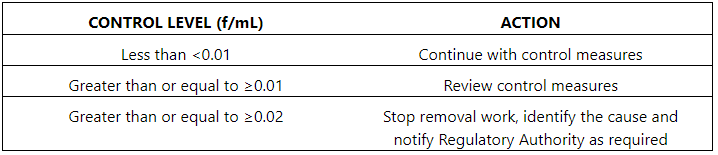

Table 1 defines the ‘control levels’ of airborne ACM fibre concentrations, which, if exceeded within the filters of the personal air samplers will instigate a series of actions to rectify the situation (ref: Code of Practice for the Safe Removal of Asbestos 2nd Edition [NOHSC:2002 (2005)]).

Table 1: Control Levels - AIRBORNE ACM Fibre Concentrations outside the ACM exclusion zone

Note: The planning stage must consider the extent and scope of clearance inspections. After an area has been cleared of ACM and prior to occupation/re-occupation a thorough clearance inspection must be completed. Clearance inspections must only be undertaken when ACM removal and decontamination have been completed, noting that airborne fibre monitoring may be required during and after removal.

R For friable asbestos, a clearance inspection must be conducted by a Competent Person who is independent of the licensed contractor responsible for the removal work. The Competent Person must formally issue a final clearance certificate with reference to the asbestos register.

Legal and Other Requirements

- Health (Asbestos) Regulations 1994

- Safe Removal of Asbestos 2nd Edition [NOHSC:2002 (2005)

- Management and Control of Asbestos in Workplaces [NOSHC: 2018 (2005)]

- Control of Workplace Hazardous Substances [NOSHC:1005 (1994)]

- AS3544:1998 – Industrial Vacuum Cleaners for Particulates Hazardous to Health

- AS4260:1997 – High-efficiency Particulate Air Filters (HEPA) – Classification, Construction and Performance

- Landfill Waste Classifications and Waste Definitions’ – classified as a Special Waste (Type 1)

- Guidelines for Health Surveillance [NOSHC: 7039 (1995)]

- How to Manage & Control Asbestos in the Workplace Code of Practice (Qld) 2011

- How to Safely Remove Asbestos Code of Practice (Qld) 2011

Document Control

Version 1 August 2019 – New Procedure