Formwork

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Definitions

Competent Person - A person who has acquired through training, qualification or experience the knowledge and skills to carry out specific activities ie. Formwork Supervisor or Leading Hand.

Hazards

Potential hazards include, but are not limited to:

- Access

- Work at heights

- Falls / falling objects

- Collapse

- Penetrations.

Design

E Formwork systems must be designed and certified by a Qualified Person (engineer).

Formwork design must:

- Comply with the requirements specified in AS 3610 formwork for concrete.

- Be project-specific

- Be signed by a Qualified Person (engineer) or accompanied by a certification letter that lists the drawing and revision numbers

- Be detailed on up to date drawings/plans

E Design documentation must include but not be limited to the details of:

- All formwork systems to be used on site including conventional systems, stairs, vertical and integrated systems

- Proprietary fittings / systems / materials to be used

- Plans, elevations, sections, loadings/ load capacity, details for any component and arrangement of any components etc. and

- Details for tying, temporary support, propping (sizes, type, location, bracing, fixings and maximum extensions) and back propping.

E Any change to the formwork design or installed system must be certified by a Qualified Person (engineer).

R A risk workshop (NSW, QLD and WA) or peer review (VIC) should be conducted before commencement of formwork & concrete placement activities on the project. The risk workshop must be attended by MPX project and subcontractor management representatives. The risk workshop must be documented and include but not be limited to:

- Construction methodology/sequence of work

- Foundations for formwork components (frames props etc.)

- Interface with other construction work, other structures, proximity to project boundaries, public and traffic

- Working hours

- Weather conditions

- Materials and systems to be used

- Plant and equipment requirements (craneage, concrete placement, transport, vertical transport, lighting, power, water etc.)

- Cantilevered elements

- Intended loads

- Loading / unloading / placement and storage of plant, equipment and materials

- Reinforcement installation

- Concrete placement method

- Temporary and emergency access

- Edge protection

- Stripping and removal of components: and

- Emergency management provisions.

Planning

All formwork must be designed, manufactured, erected, disassembled / stripped & maintained in accordance with AS 3610 Formwork for concrete.

Prefabricated formwork systems must be constructed and dismantled in accordance with the manufacturer’s specifications and/or Qualified Person (engineer) instructions.

Metal deck formwork systems must be In accordance with:

S SWMS’s are required for high risk work activities associated with formwork, reinforcement installation and concrete placement. SWMS’s must be submitted to MPX for review prior to the commencement of high risk work activities associated with formwork, reinforcement activities and concrete placement

Overhead works / Work at heights must be in managed in accordance with:

- Section: Cranes Hoists and Other Lifting Equipment

- Section: Overhead Works Coordination

- Section: Plant and Equipment.

- Section: Working at Heights

Operational

Materials

Materials must only be delivered to the project if authorised and scheduled in coordination with MPX.

Materials must be delivered to the project such that they can be safely unloaded by load shifting equipment (crane, forklift, telescopic handler).

Materials must be securely stored in consideration of adverse weather).

Materials must be removed from the project such they can be safely loaded by load shifting equipment (crane, forklift, telescopic handler).

Training and Competency

R All people involved with formwork, reinforcement installation and concrete placement must be inducted into the relevant SWMS,

Inspection

E A Qualified Person (engineer) must inspect the formwork and provide a written report, certificate of compliance or similar to MPX prior to the placement of concrete. The report / certificate must state that the formwork complies with AS 3610 and the formwork design.

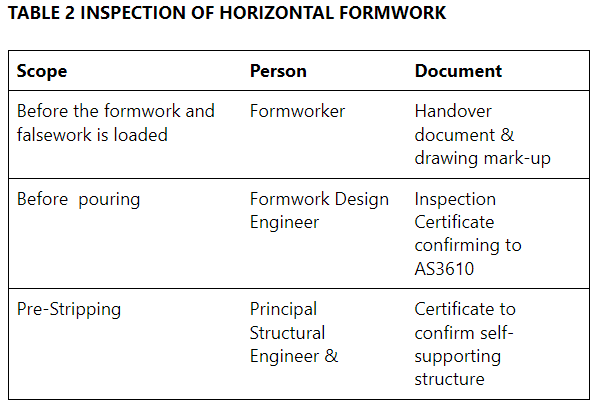

R Horizontal formwork must be inspected in accordance with the Table 2.

R The formworker contractor must inspect the formwork prior to the placement loads.

R Formwork must be inspected by the form worker prior to commencing work after any significant weather event and the condition of the formwork must be reported to MPX.

A competent designated observer should continuously monitor the formwork assembly during concrete placing operations and be provided with an appropriate communication system to alert others in case an emergency arises.

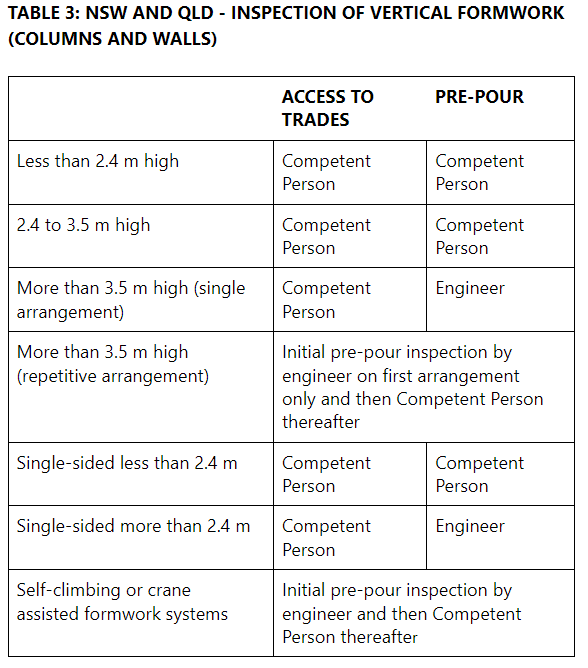

R VIC and WA - Vertical formwork (columns and walls) must be inspected by a Competent Person.

R NSW and QLD - Vertical formwork (columns and walls) must be inspected in accordance with the table 3.

R A MPX and subcontractor concrete pre-pour checklist must be completed prior to the placement of any concrete.

Exclusion Zones

Formwork, reinforcement installation and concrete placement work areas must be isolated via use of barricading and signage to define work areas as per:

- Section: Barricading and Signage.

Where exclusion zones are established and they affect access, alternative access must be defined. The workforce must be informed of alternative access routes.

Excavation

Excavation for any formwork must be in accordance with:

- Section: Excavation

Foundations

Frames / props must be based on firm ground, with sole boards / base plates or as specified by a Qualified Person (formwork engineer). The suitability of the ground must be verified by a Qualified Person (geotechnical engineer).

Where practicable, the foundations should be periodically inspected and after any significant weather event.

Pits / Tanks etc.

The construction of any pit, tank or similar formwork must be assessed for the potential risk associated with confined spaces or restricted access.

Where defined as a confined space the work must be carried out in accordance with:

- Section: Confined Space Entry.

Vertical elements

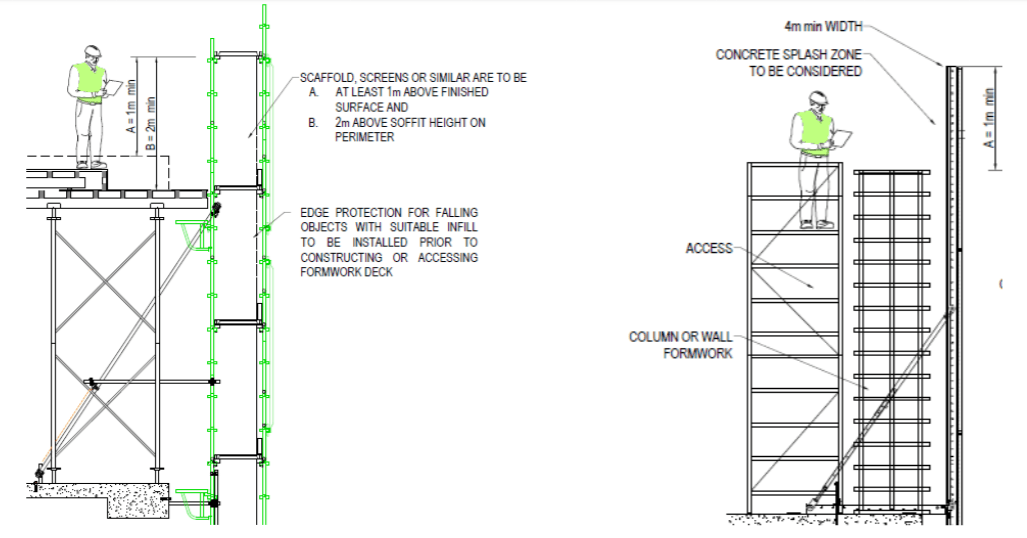

Access for the construction of vertical elements (columns, walls etc.) must be via scaffold, mobile elevated work platform or propriety work platform.

Vertical elements must be propped or otherwise supported in accordance with design documentation.

Tie rods, reinforcement bars or similar must be capped, laced or similar.

Where concrete blocks are used to support propping, the weight of the concrete block must be clearly marked.(kilograms or tonnes)

Suspended Formwork

Before access is provided, consultation between MPX, formworkers and other trades should be undertaken to provide a suitable hand over of completed elements of the formwork deck.

Access to formwork zones must be restricted to authorised persons only:

- Signage must be displayed ‘DANGER – formwork in progress authorised access only’ or similar.

Access under suspended formwork decks must be defined with signage and barricading.

Suitable access lighting must be provided where required.

NSW and VIC - At least one (1) access to each formwork deck should be via ladder access.

WA - At least one (1) access to each formwork deck must be via double width scaffold stair. Where other access is provided a single width scaffold stair or stairs is permitted. Single ladder access is not permitted unless authorised by MPX.

- Where single ladder access is permitted, use must be restricted for the purpose of installing edge protection and the infill of penetrations.

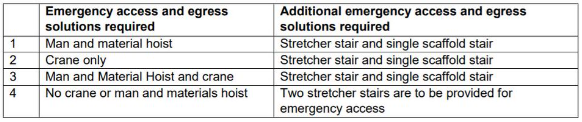

QLD - Dual access and egress must be provided to work areas as per table 4

Suitable walkways must be provided on the formwork deck/beams especially were reo has been installed. Where a beam is two (2) or more metres deep, edge protection must be installed and access into the beam provided.

Intermediate Deck / Platform

Intermediate decks must be installed where a potential fall distance is greater than 2m. The platform must be in place with edge protection to prevent falls from height.

False Decks

NSW and QLD - In situations where a deck is at a height that would require workers to stand at heights of 2m or more to install bearers and joists for the formwork deck, a continuous ‘false’ deck , which is a full deck the same area as the floor being formed, should be provided. Refer to the figure below.

NSW and QLD - Worker erecting formwork from an intermediate platform less than 2m above a formwork deck where the deck to deck height is greater than 2m

QLD -- The false deck should be constructed so there are no large gaps and that gaps only exist where a vertical member of a frame passes through the deck. Gaps should not exceed 225mm in width.

NSW, and VIC - The false deck should be constructed so there are no large gaps that can create a potential fall from height.

WA - the false deck should be constructed such that gaps do not exceed 200 x 200mm.

Edge protection systems must be constructed from steel or timber engineered system (WA - timber is not permitted unless approved by MPX) and

QLD, VIC and WA - Edge protection systems must incorporate mesh panels.

Leading edge protection must take into account the final height of the slab and extend at least 900mm above the Finished Floor Level or highest working surface on the leading deck.

Perimeter edge protection must extend at least one (1) metre above the highest formwork deck.

Infills and other penetrations must be completed in sequence with the installation of the formwork deck.

Penetrations in general must be in accordance with:

- Section: Penetrations in Floors

Prior to permitting access to other contractors, the formworker must complete all perimeter edge protection, any penetrations must be in-filled or excluded with hard barricading and signage.

The leading edge must be defined with signage and hard barricading installed at least two (2) metres back from the leading edge. Form workers requiring access to the leading edge must work in accordance with:

- Section: Working at Heights.

- Section: Edge Protection

Edge protection must be installed on vertical openings/penetrations on any stair, lift core or similar, refer to:

- Section: Lift Shafts.

Needles, tie rods, reinforcement bars or similar must be capped, laced or otherwise protected.

Temporary power, water and fire extinguishers must be made available on the suspended formwork deck.

Any prop or other type of temporary support located on a building edge (including penetrations, risers or stairs) is to be securely fastened (on the top) in position.

QLD - Perimeter edge protection systems for falling objects during formwork activities are to comply with the following examples:

Legal and Other Requirements

- Formwork Code of Practice (Qld) 2016

- AS 1302 Steel reinforcing bars for concrete

- AS 3600 Concrete structures

- AS 3610 Formwork for concrete

- AS 4672 Steel reinforcing materials.

- AS 4994.4 Temporary edge protection , perimeter protective screens

- AS 6669 Plywood - formwork.

- AS 4100 Steel Code

- AS 1539 Cold Formed Steel Structures Code

- AS 1170.1 Loading Code

- AS 1170.2 Wind Loads

- AS 1657 Fixed Platforms, Walkways, Stairways and Ladders

- AS 1720.1 Timber Structures Code

- AS 4991 Lifting Devices

- Safe Work Australia Guide: Formwork

- Safe Work Australia Guide: General guide for formwork and falsework

- Safe Work Australia Guide: Slip, jump and travelling formwork systems

- Safe Work Australia Information sheet: Formwork and falsework

Document Control

Version 1 August 2019 – New Standard

Version 2 December 2019 - Removal of the specific QLD requirements realting to formwork design.