Hoists

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Note: This section is to be read in conjunction with:

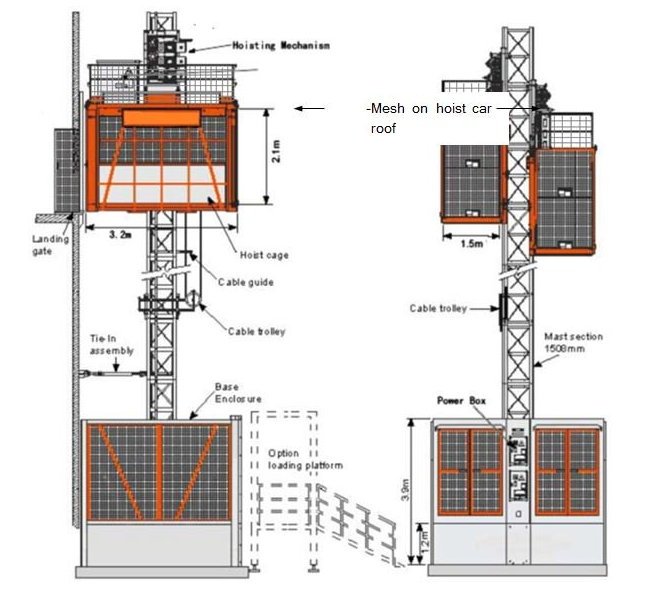

Personnel/ Material Hoists (e.g. Cantilevered Builders Hoists).

Design and Planning

E A Qualified Person (structural engineer) must be engaged to review the hoist design, hoist base and review/approve the load and connection methods to the building

R Evidence of WHS authority registration of plant design is required for Personnel & Materials Hoists (only)

R Risk workshops should be held and documented for Hoist erection and dismantling.

- In addition to the planning requirements listed in Cranes, Hoists and Other Lifting Equipment - General consideration of the following is required:

- Allowance for the hoist overrun

- Power availability and location of board

- Type, number and size of hoists

- Proximity relative to other hoists for climbing, servicing/maintenance and dismantling activities

- Correct siting of the hoist having regard to the intended location of crane and other plant, overhead power lines, nearby structures, access areas (including building doors, windows, and all other openings), location of operator controls, site access and work sequences which must be undertaken.

- Exclusion zones.

- Pit design with consideration to the door opening – where applicable

- Pit design to consider drainage – where applicable

- Adjoining platforms, (if required) are to at least match the hoist car SWL capacity and to be designed by a qualified person.

Training and Competency

R Hoists must be installed, climbed, dismantled, and operated by a Competent Person. The hoist operator must receive hoist familiarisation for the make/model of hoist to be operated., refer to:

Commissioning and Pre-operation

R The hoist installer must provide a commissioning report (including on-site drop test/brake test results) for the installation. For each jump, the hoist installer must provide a handover inspection report

- NSW and ACT - Commissioning tests after installation must be completed on-site and witnessed by a Multiplex representative.

R VIC and QLD - A Personnel and Materials Hoist checklist must completed before commencing operations.

Operational

S A SWMS must be developed and implemented for the erection, climbing, maintenance and dismantle of hoists.

S A SWMS must be developed and implemented for hoist operation.

R A plant risk assessment must be provided by the hoist supplier/installer.

All installation, alterations, servicing and/or jumping activities on any dual twin hoist cars on single mast configuration must be carried out whilst both hoists cars are locked off and under the control of the contractor performing works.

Hoists must:

R Have a log book, kept up to date (by the operator)

- Have instructions and maintenance records available

- Be inspected, serviced and maintained in accordance with manufacturer’s recommendations

- Be set up on compacted ground and be maintained vertically (needles and screw jacks packed with timber and tightened)

- Not be free standing more than 3 metres above the last tie as per the Original Equipment Manufacturer (OEM) manual unless otherwise approved by OEM or Engineering Design

- Be braced or guyed (irrespective of height), be supported by a lateral brace, not more than 6 metres above base and at least every 6 metres thereafter or guyed (for material hoists only)

- Materials stored within hoist cars should be adequately stacked/stored/secured to prevent their movement during vertical travel of the hoist car

- Include the provision of wheel stops or similar barriers to prevent items like electric pallet jacks from falling out

- VIC/QLD - Be fitted with a defibrillator and oxy viva set (personnel & materials hoists only) (QLD – if a twin hoist setup, a defibrillator is only required to be installed in one of the hoists)

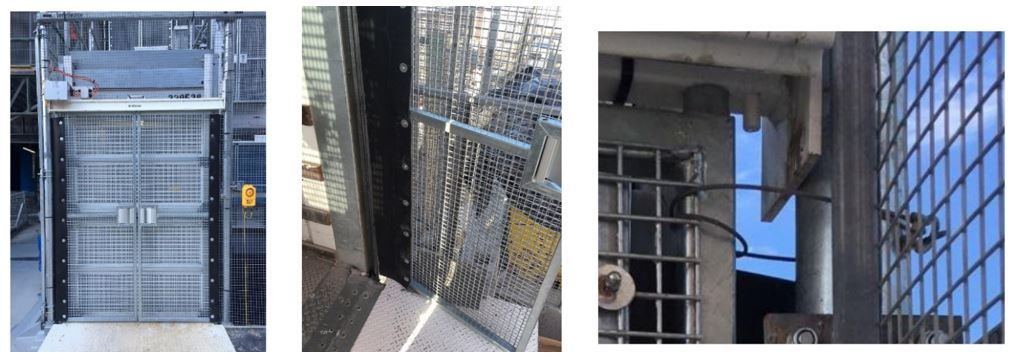

- Be fitted with guardrails, mid rails, kickboards and have mesh panels or similar installed on the roof edge protection. (Photo 3)

- Be fitted with platform gates that may incorporate a fold down section to bridge the gap between the platform and landing. Chain or rope is not acceptable as a gate

- QLD Be fitted with a constant pressure switch or device to prevent inadvertent operation.

- All hoists must have base guarding (base level guardrailing) erected on all four sides of the platform landing area

- Materials Hoists (only) must have overhead protection provided where the control panel is within 3 metres of the hoist

- For Personnel and Materials Hoists, protection at landings must be at least 2.4 metres high, and shall be installed both above the landing gate and above all parts of landings which are within 800mm horizontal reach of any vertically movable hoist components (including ropes and counterweights); or within 800mm horizontal reach of the outside face of any unmeshed hoist support tower

- For Materials Hoists, protection at landings must be at least 1.8m high, and shall be installed above all parts of landings which are within 800mm horizontal reach of any vertically movable hoist components (including ropes); or within 800mm horizontal reach of the outside face of any unmeshed hoist support tower

- VIC, NSW, QLD – Have landing gates at least 1.8 metres high, meshed above the gate and equipped with integrated, gate-interlocked circuit wiring.

- VIC, NSW, QLD - Have gaps between the hoist gates and access platforms / landings / soffits covered with mesh / plywood or similar. (Photo 2)

- VIC, NSW, QLD - Have the external doors fitted with a lanyard or a secondary control to prevent a door from being inadvertently lifted off the hinge. (Photo 2)

- WA - Have gaps between hoists gates and access platforms / landings covered with mesh / plywood or similar

- WA - Have landing gates at least 1.8 metres high and equipped with integrated, gate-interlocked circuit wiring.

- Have power cables appropriately restrained with sufficient guides for the prevailing conditions.

The cable drum must be loaded evenly with cable, to prevent any freefall.

- The hoist and platform must be suitably signed indicating working load limit, name/mark of manufacturer, model ID, rope and reeving detail: calibration date (rack & pinion), owner’s ID and for Materials Hoists a sign indicating “persons are prohibited from riding the platform”.

- The potential risk of falling objects during the installation, climbing, maintenance and dismantling of the hoist should be managed in accordance with

- Section: Working and Heights and consider:

- Tools being secured to lanyards

- Rattle guns/ratchets etc. having magnetic sockets

- Exclusion zones with signage

- Overhead protection

- Tools and equipment to be contained when not in use

Inspection and Maintenance

R Inspection and maintenance must be in accordance with the manufacturer’s specifications and:

R Hoists must have a logbook, kept up to date (by the operator)

- Have instructions and maintenance records available

- Be inspected, serviced and maintained in accordance with manufacturer’s recommendations

Click on image to open an enlarged version

Legal and Other Requirements

- AS 1418.1 Cranes (including hoists & winches) - general requirements

- AS1418.7 Cranes (including hoists and winches) – Builders hoists and associated equipment

- AS 2550.1 Cranes, Hoists & Winches – Safe Use – General Requirements

- AS 2550.7 Cranes, Hoists & Winches – Safe Use – Builders’ Hoists and Associated Equipment

- Managing Risks of Plant Code of Practice (Qld) 2013

Document Control

Version 1 August 2019 – New Standard

Version 2 February 2025 – Additional requirements added relating to planning, wheel stops, external doors and inspections and commissioning tests.