Lift Shafts

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Operational

Following the construction of a lift shaft the formwork subcontractor must protect the vertical opening. This protection must remain in place until the lift installer, installs their lift cages.

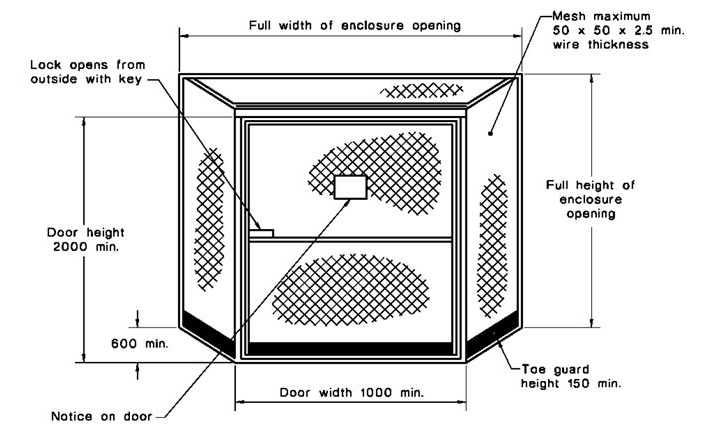

Prior to the lift installer commencing work, the lift installation contractor must fit each lift shaft opening (door) with a full height cage which prevents unauthorised entry and prevents risk of falling people or materials:

E Lift shaft cages must be in accordance with AS 4431

- The lift shaft cage must be hinged and lockable

- Lift shaft cages must be fixed to the wall and/or floor using concrete anchor bolts or similar

- Lift shaft cages must be signed ‘Danger no unauthorised entry’ or similar and have the lift installer contact details

- Materials must not be stored inside of lift shaft cages

- Lift shaft cages must be closed at all times. Where lift shaft cages must be open, a lift installer must be present and an internal safety rail must be fitted. Alternatively, the false car may be driven up to the same level as the lift shaft cage opening.

S A SWMS statement must be developed and implemented for lift installation work including emergency procedures

S The lift installer must implement emergency procedures for rescue of an employee from the lift shaft and for rescue due to false car or lift breakdowns

R All people carrying out lift installation work must be inducted into the applicable SWMS.

All rigging works must be undertaken by licensed riggers: where there is a need to work at heights, lift installers must be trained: and all electrical works must be undertaken by a licensed electrician.

Scaffold must be erected in accordance with:

- Section: Scaffolding

E Where works are undertaken concurrently above the lift installers (i.e. jump-form / slip-form), overhead protection must be installed to separate the works and rated to

- WA 7 kPa

- NSW and QLD 10 kPA.

- VIC 10 kPA with a rubber mat and aluminium checker plate

Temporary access (e.g fitted single-rung type ladder) must be provided for access into lift pits.

Consideration must be given to drainage of water, via lift over-run pits.

Suitable lighting with an equivalent lighting level of a 60 lux must be established where workers are working in the lift shaft.

Construction wiring dedicated to the installation of lift shaft equipment must consist of a separate final sub-circuit.

Circuit breakers must be locked off and tagged to prevent inadvertent isolation of supply to the lift shaft by others on the site.

Lift installers must not work alone / unsupervised in lift shafts.

Access to lift motor rooms must be restricted (via keyed lock) and limited to the lift installer and MPX.

The supply should be provided for the sole purpose of providing adequate power to the climbing hoist, task lighting and power for the use of electrical tools when working from the false-car working platform.

False-Car (Guided Work Platform)

R All people carrying out false car work (installation and operation) must be inducted into applicable SWMS and hold valid records of competency / training, evidence must be retained on site.

E The lift installer must induct false car operators.

E The lift installer must provide a “safe for use” (installation and test) certificate prior to use.

R Daily inspection logbooks must be available and completed by the operator prior to each use.

The false car SWL must not be exceeded and must take into account weight of the operator, passenger(s) and equipment/materials.

The false car must be operated and maintained in accordance with manufacturers specifications.

- Electrical wiring providing supply to the false-car working platform must be heavy duty double insulated flexible cord or cable.

Work by Others

Where others (other than the lift installer) require access into the lift shafts in order to undertake work:

- P WA - They must apply for permit to work, Lift shaft access

- MPX must liaise with the lift installer to coordinate other works

- S A task-specific SWMS must be developed and implemented

- WA - The SWMS must be attached to the permit to work Lift shaft access

- People carrying out work in the lift shaft must be supervised at all times by the lift installer

- The lift installer must operate the false car for the other subcontractor

P WA - Upon completion of the work, the subcontractor must inform MPX and the permit to work Lift shaft access must be closed out.

Concrete cutting is not permitted to be undertaken from inside the lift shaft, unless specifically authorised by MPX. Where authorised the work must be in accordance with:

- Section: Concrete Coring, Cutting, Drilling, and where applicable

- Section: Confined space entry

Western Australia

Legal and Other Requirements

- AS 4431 Guidelines for Safe Work on New Lift Installations in New Construction

Document Control

Version 1 August 2019 – New Standard