Extension Leads

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Operational

Extension leads must:

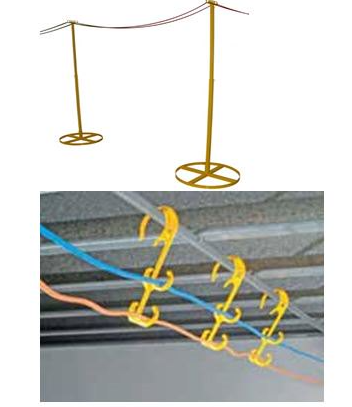

- Be protected against mechanical damage, damage by liquids or damage by high temperatures and as far as is practicable, be supported above the ground on insulated stands or hangers.

- Not be directly attached to scaffold , including aerial cables

- Other than in stairs, lift shafts, service shafts, formwork, external staging or submains of construction wiring: extension leads be confined to the level of the switchboard from which they originate.

- Be tested and tagged every 3 months as per portable electrical equipment.

- Have a minimum conductor area of 1.0 mm² or greater and contain an earth conductor.

- Not contain the colour green in the protective outer sheath.

- Be uncoiled when in use.

- Be heavy duty type

- Have moulded, nonrewireable or transparent type plugs

The use of insulated hooks/hangers can be used to support lead/cords

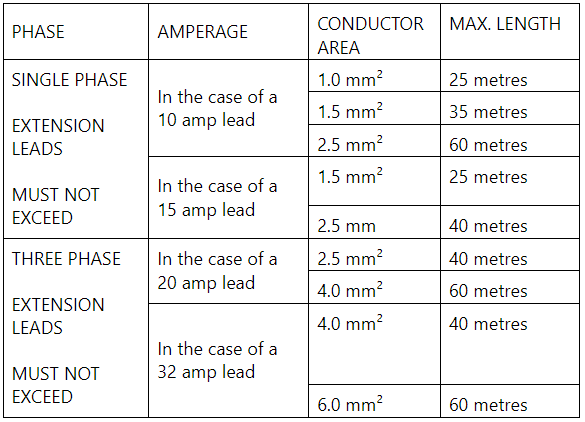

Lead Lengths

Table 1: Lead lengths

Document Control

Version 1 August 2019 – New Standard