Hot Work

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Hazards

Potential hazards include, but are not limited to:

- Burns

- Fire / explosion

- Fumes

Definition

Hot work is defined as, work which involves welding, cutting, heating works or activities likely to cause risk of fire.

Examples include all welding-type works, soldering, brazing, gas cutting, use of naked flames, heat guns, blow torches, gas torches, heat cutters (e.g. hot knife, hot wire), grinding of materials which may cause spark or cause an ignition (e.g. heat) and electro-fusion jointing (welding).

Planning

Hot work must only be undertaken where permitted by MPX.

P A permit to undertake hot work must be issued by MPX prior to commencement of hot work.

- The hot work permit must be closed out once the work has been completed.

S Subcontractor’s in conjunction with MPX must document the hot work permit requirements and associated task-specific hazards and controls in their SWMS.

SWMS must give due consideration to:

- Equipment manufacturer’s instructions

- Access/egress to work areas

- Other workers

- Potential atmospheric contaminants (gas, dust)

- Atmospheric monitoring (equipment)

- Ventilation

- Isolation of any energy supply/ service

- Flammable material

- Personal protective equipment

- Barricades and signage

- Welding screens

- Storage of welding equipment and gas cylinders

- Control for falling slag/sparks etc.

- Firefighting equipment, lighting, spotters, fire watch

- Traffic (vehicular or pedestrian) management issues

R The people carrying out the hot work activity must initial / sign the hot work permit and SWMS, confirming they understand the requirements and intent to comply with the risk controls.

Conditions apply when total fire ban days are declared

WA and VIC - Where a total fire ban day is declared, all active hot work permits must be suspended. Subcontractors must reapply for a hot works permit in compliance with the relevant authority (i.e. WA - Dept. of Fire and Emergency Services).

VIC - Where a total fire ban day is declared, a hot works permit must be in compliance with the relevant authority (i.e. Melb Fire Brigade, Country Fire Authority)

Operational

R All persons involved in welding or similar must have a record of training/ certification. Records must be available and be produced when requested:

Where hot work is being undertaken the area (5 meter radius) must be clear of flammable materials.

- Where potentially flammable materials etc. are present they must be protected from direct heat, slag, sparks etc.

Barricades and signage and welding screens or similar should be used, refer to:

- Section: Barricading and Signage.

Services adjacent to where hot work is occurring must be assessed and where required isolated or otherwise protected prior to commencing the work, refer to:

WA - Hot work in a confined space must be in accordance with:

- Section: Confined space entry

Where flammable or explosive atmospheres, gases or dust may be present, gas testing must be performed by a certified gas testing agent.

R The area must be declared gas free: results must be attached to the hot work permit.

- Gas testing must be carried out at intervals or continuously as specified by the gas testing agent.

Firefighting equipment must be supplied by the subcontractor undertaking the hot work, be serviceable and available where hot work is being carried out.

A fire extinguisher is to be easily accessible in the vicinity) where any hot work is being carried out i.e. welding.

If during the hot work, a fire occurs, gases are released or an injury occurs, work must cease immediately:

- The incident reported to relevant subcontractor’s supervisor and MPX as soon as practical.

Nominated fire watch persons must be identified on the permit to work and remain present for the duration of the fire watch (nominally 30 minutes).

Equipment – In use

Electric welding equipment must be inspected prior to use by the operator and be tested and tagged refer to:

- Section: Electrical.

Gas cylinders and fittings must be free from oil and grease.

Gas cylinders must be upright, secured and protected from excessive /artificial heat sources (note: direct sunlight can represent excessive heat in some circumstances)

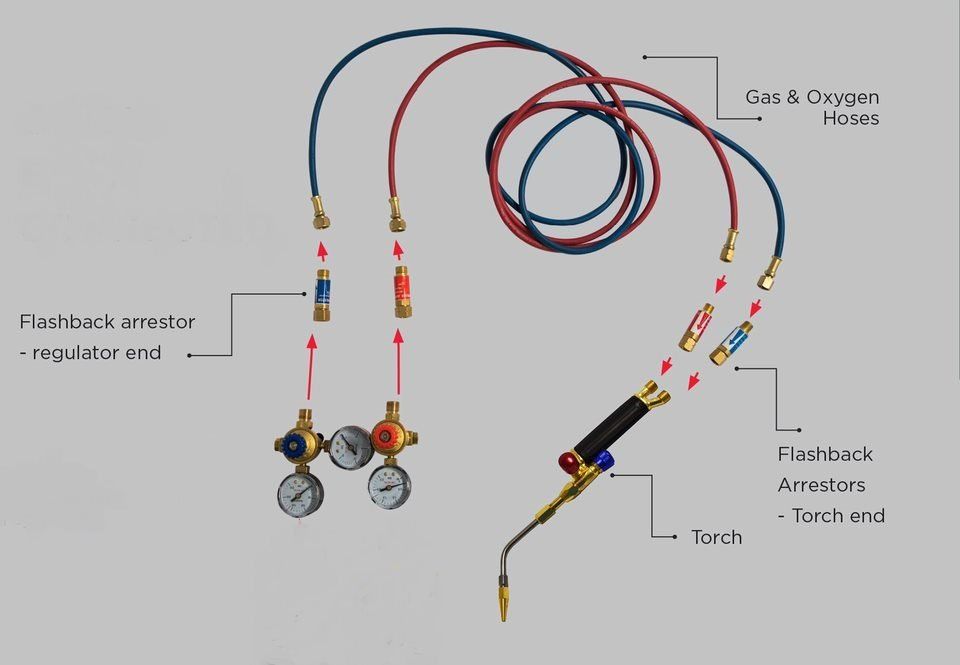

Oxy acetylene equipment – flash back arrestors must be fitted and serviceable (four (4) arrestors, two (2) on each hose with one (1) at each end) with gauges adequately protected.

Equipment - In storage

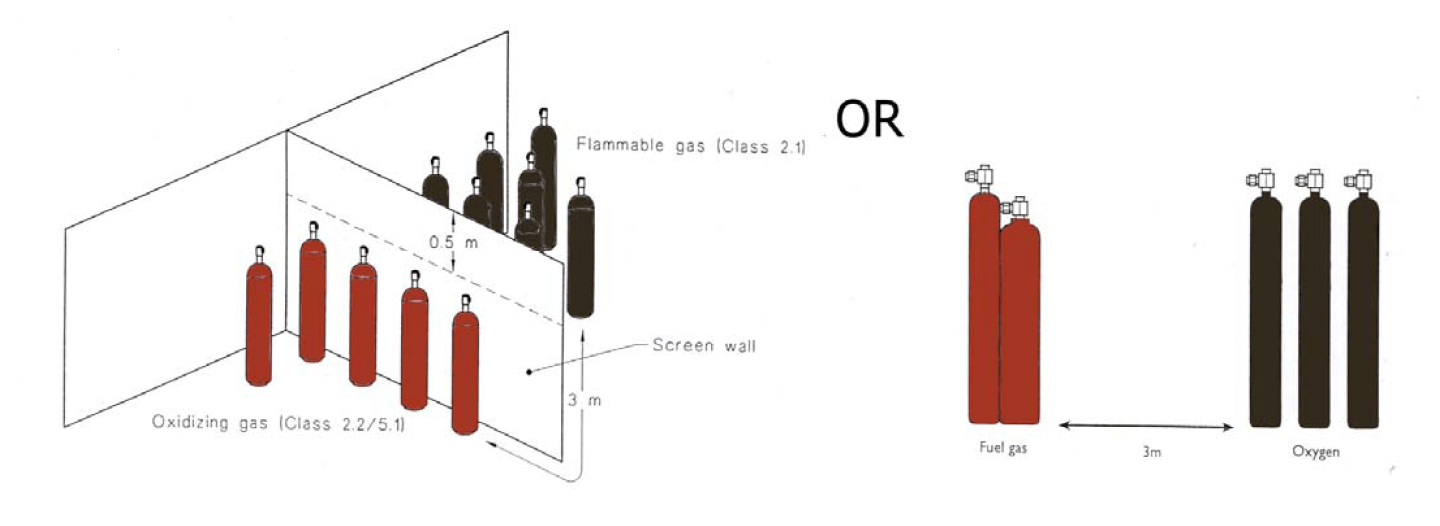

Oxygen, acetylene cylinders in bulk storage must be stored and stored 3 metres apart or separated by a firewall (oxy / acetylene).

Gas cylinders must be stored in well ventilated areas, protected from artificial / excessive heat sources, secured in cages, and clearly signposted

As far as reasonably practical gas cylinders bulk storage should be limited within the confines of the building.

For information in reference to power tools used for hot work e.g. grinders refer to:

- Section: Power tools and Ancillary Equipment.

Personal Protective Equipment (PPE)

Persons undertaking hot work must wear appropriate PPE e.g. protective clothing/ welding apron, welding mask/face/eye protection, gloves, hearing protection, and safety boots.

Legal and Other Requirements

- Bush Fires Act 1954

- Bush Fires Regulations 1954

- 1674 Safety in welding and allied processes

Document Control

Version 1 August 2019 – New Standard