Lead Paint (Paint and Dust)

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

Lead paint is defined by the Australian Standard (AS/NZS 4361.2 – 1998 Guide to lead paint management Part 2: Residential and Commercial buildings) as a paint or component coat of a paint system containing lead or lead compounds, in which the lead content (calculated as lead metal) is in excess of 1.0% by weight of the dry film as determined by laboratory testing.

Lead can enter the body mainly through ingestion (via contaminated food & drink) or inhalation of fumes or dusts. When absorbed into the body, lead will circulate in the blood and can remain in the soft tissues and organs (e.g. kidneys, liver and brain) and is stored in bone and teeth.

Lead absorption through the skin is very slow although repeated exposure to low levels of lead can cause it to build up in the body. Care should therefore be taken when handling lead flashing to avoid contamination of hands or clothing/PPE potentially leading to ingestion and be marked for transport to an authorised facility avoiding the creation of dust or contact where possible.

Where applicable the project-specific Lead management sub-plan or Lead Removal Control Plan should be read in conjunction with the following information.

Planning

During project development stages and prior to commencing work in existing buildings, where risk assessment i.e. age of the building determines the presence of lead is likely, a HAZMAT survey must be undertaken to verify the presence of lead.

Where presence of lead is confirmed and lead interference works are likely, in accordance with AS/NZS 4361.2, an Occupational Hygienist must be engaged to undertake a baseline survey to establish existing site conditions prior to commencing works and determine whether the lead removal activities are minor or major and whether a lead removal control plan is required.

- Baseline survey will include testing of soil and additional sampling

During construction, demolition or refurbishment of a project, the management of potential site contamination (including contaminated soil, groundwater or surface water) and risk to people’s health must be minimised and lead management sub-plan developed.

Construction activities that have the potential to impact on lead contamination on site include but are not limited to:

- Demolition

- Block laying and associated works

- Painting

- Plastering and associated works

- Steel erection and associated works

- Heritage works and

- Service Installation.

Lead-based Paint

Where lead-containing paint has been identified there are four potential management options:

- Do nothing – generally where paint is in good condition, is not accessible or is an undercoat which has been overpainted with non-lead-based paint:

- Stabilise the paint – usually by overpainting with a non-lead-based paint (typically oil based). For this option to be successful any defects such as flaking of the existing paint must be remedied prior to over-painting: it is to be noted where existing lead paint is in poor condition it will need to be removed by stripping back to the substrate or sound surface for warranty purposes. It is important that the correct paint system is used when over painting as not all paints seal the lead and if the incorrect paint system is used lead transfer can occur through the coatings.

- Encapsulation This is similar to over-painting but with the exception of the use of high build paints such as 2-pack paint systems.

- Replace / enclose / remove the paint or painted item Replacement is normally used for easily replaceable items such as doors, gutters or downpipes: removal of the paint is often required if the paint is in poor condition and is readily accessible: while enclosure can be utilised where it is possible to enclose the item (such as a column where gyprock cladding could be erected around although this may affect the purpose of the item or the character of the building): or

- A combination of the above 4 options.

S Where minor interference with lead-based materials or surfaces is planned, the subcontractor will be required to submit a task-specific SWMS for applicable works outlining the processes for managing works involved interference with lead paint, in accordance with the project-specific lead management sub-plan.

- The SWMS must be developed in consultation with the people doing the work and take into account specifics from the applicable Australian standards and codes of practice which relate to lead.

S Where major interference with lead-based materials or surfaces is planned the subcontractor must prepare a lead removal control plan / lead paint management plan, detailing the subcontractors approach to managing works involved interference with lead paint.

R Where applicable the subcontractors interfering with the lead must provide MPX with evidence of notification to Regulatory Authority where applicable.

Inspections / Surveys

R Inspection must be completed in accordance with the Lead management sub-plan / Lead Control Removal Plan.

R Once lead interference work is complete, a clearance survey must be undertaken by an Occupational Hygienist to confirm works have not caused contamination.

Atmospheric Monitoring

Atmospheric monitoring involves the periodic and/or continuous sampling of workplace atmospheres to derive a quantitative estimate of the potential inhalation exposure.

Air sampling techniques and strategies for estimating atmospheric lead concentrations are set out in National Code of Practice for the Control and Safe Use of Inorganic Lead at Work, appendix 2.

- The results of atmospheric monitoring should be compared with the lead exposure standard.

MPX may employ atmospheric monitoring based on the recommendations of an Occupational Hygienist. MPX retains discretion in undertaking this monitoring during the course of the works.

Decontamination and Hygiene Facilities

Subcontractors interfering with the lead must provide decontamination and hygiene facilities in accordance with the lead control removal plan.

Health Surveillance

Health surveillance is required for people who are undertaking interference activities with lead-based materials or surfaces.

- The names of these people must be communicated to MPX

Participation in health surveillance is mandatory unless there is some compelling reason to the contrary, in which case the matter must be discussed with the person responsible (medical practitioner) for the health surveillance program.

Health surveillance will take the form of a blood test to establish the employees blood lead levels prior to commencing a lead interference work.

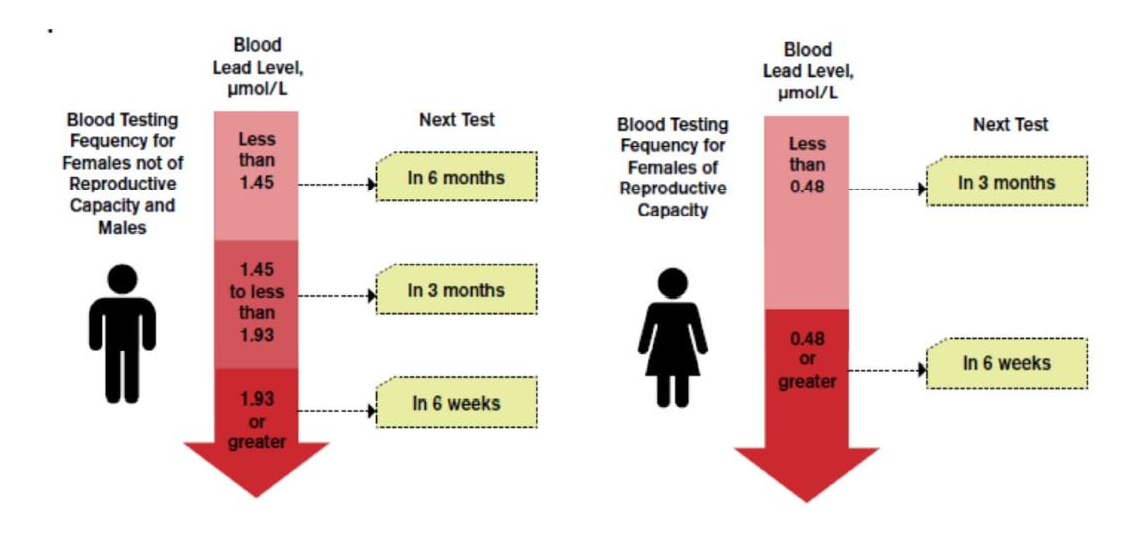

- Follow up blood test will be undertaken at intervals defined by the medical practitioner or Figure below

Health surveillance should not be used as an alternative to other control measures.

- Any costs borne by health surveillance are at the employer’s expense.

Health surveillance which includes biological monitoring can assist in minimising the risk to health from exposure to lead by:

- Confirming that the absorbed dose of lead, determined as blood lead, is below the specified removal level of the National Standard for the Control of Inorganic Lead at Work [NOHSC:1012(1994)]

- Indicating biological effects

- Verifying that individuals who should be excluded from working in leadrisk jobs because of personal medical conditions, are appropriately identified, or

- Collecting data to evaluate effects of exposure to lead.

Training and competency

People undertaking lead interference work must as a minimum should receive information and instruction on:

- Safe work methodology (e.g. Methods in dust reduction, including the use of HEPA vacuums and emptying contents)

- Health surveillance

- Selection and use of respiratory protection equipment

- Labelling requirements for of leadcontaining substances

- Personal hygiene

- Waste management and disposal requirements.

Tools and Equipment

Pneumatic, mechanical or electrical tools must be fitted with on tool extraction/ collection / suppression systems. These tools and their filters be inspected prior to use damaged, faulty or inoperable tools must be removed from service.

- Any used/worn filters must be bagged and labelled for disposal in a designated waste receptacle.

All tooling must be wiped down or otherwise cleaned after use. Maintenance must be in accordance with the manufacturer’s specifications.

Suitable exclusion zone must be established in accordance with SWMS / lead removal control plan, refer to:

- Section: Barricading and Signage.

PPE

People involved in the lead paint interference or entering an area where the work is occurring must be provided with PPE and are required to wear / use / dispose of PPE in accordance with the SWMS / lead removal control plan. Example of PPE include:

- P2 particulate filter respirators

- Disposable overalls / dust coat to be worn over clothing

- Gloves.

All PPE must be removed prior to leaving the work area, and disposable items discarded as per lead control removal plan.

Legal and Other Requirements

- AS/NZS 1715: Selection, use and maintenance of respiratory protective equipment

- AS/NZS 1716: Respiratory protective devices

- AS/NZS 4361.1: Guide to Lead Management - Part 1: Lead and other hazardous metallic pigments in industrial applications

- AS/NZS 4361.2: Guide to Lead Management - Part 2: Residential and commercial buildings and

- NOHSC: 2015(1994) Control and Safe Use of Inorganic Lead at Work.

- Control of Inorganic Lead at Work [NOHSC:1012(1994)]

Document Control

Version 1 August 2019 – New Standard