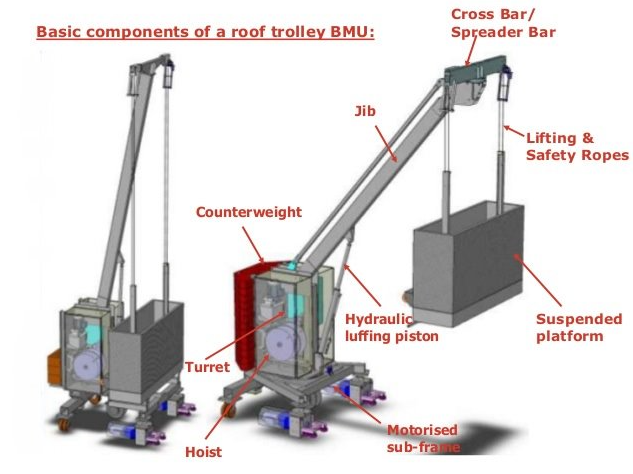

Building Maintenance Units (BMU)

References: R Record keeping requirement | E An engineering/certification requirement | P A permit to work requirement | S A safe work method statement (SWMS) / written plan

Informative

A BMU is a device that enables access to the facade of a building and is primarily used for maintenance work.

Design and Planning

E The design registration certificate from a regulatory authority must be provided by the installer to MPX.

Overhead and other proximity hazards (e.g. power-lines, building structures, and trees) must be assessed prior to use of the BMU. Clearance from these hazards must be maintained.

Installation

S A SWMS must be developed and implemented for BMU installation.

R All personnel involved in the task (installer, operator and maintenance) must be inducted into the applicable SWMS and hold valid records of training / competency, evidence must be retained on site, refer to:

E Installation of the BMU must be verified by MPX in consultation with the Subcontractor to verify compliance with the design requirements.

Following installation and prior to use, the BMU installer must provide MPX with:

- R Inspection and test records

- R Builder’s “safe for use” certificate

- Operations and maintenance manual

- R Pre-operational inspection checklist(s)

- Sets of keys

- R Induction / training documentation.

R The installer must then obtain a plant registration certificate from the regulatory authority (BMU in MPX’s name).

- Note: Obtaining the plant registration certificate will not occur immediately, so long as there is evidence the plant registration certificate has been applied for, the BMU can be operated.

Note: At building handover, a plant re-registration certificate must be obtained from the regulatory authority in the building owner’s name.

VIC -The MPX Building Maintenance unit checklist must be completed prior to operating the BMU on any occasion

Operational

The BMU installer must induct / train operators into the use of the BMU. A register of trained / inducted persons must be retained by MPX.

S Project-specific SWMS for operation is to be developed by the installer and MPX.

R BMU operators must be inducted into, and sign onto the SWMS prior to operation.

A minimum of two (2) sets of keys must be available. An MPX supervisor must be nominated to manage the issuance and return of keys:

- One (1) set of keys will be issued to the BMU operator

- Second (2nd) set retained for emergency purposes.

Emergency contacts and operating instructions must be available in the cradle of the BMU.

- The emergency contact details must include a supplier / installer contact for breakdowns.

A minimum of two (2) persons must be present in the cradle during use (i.e. for emergencies).

The BMU operator and occupants wear a fall injury prevention device at all times and be suitably trained / competent, refer to:

Lanyards must be fitted to all tools and other equipment.

R The BMU operator must complete and record daily pre-operational inspections (logbook).

Safe access must be provided for personnel access / egress the BMU.

Exclusion zones must be established below and where applicable above the BMU, refer to:

- Section: Overhead Works Coordination

A fire extinguisher must be fitted in the cradle.

The SWL of the BMU must not be exceeded: the weight of the operator, any occupants and materials must be taken into account.

Personnel and materials must be securely confined within the BMU cradle, unless the BMU is specifically designed to carry materials outside (e.g. jib attachment).

The BMU must only be operated in favourable weather conditions.

- Where conditions become unfavourable (e.g. strong wind, lightning), the operator must return the BMU to its storage position.

An effective method of communication between the occupants of the BMU and the ground must be established (e.g. two-way radio or mobile phone).

S A rescue plan must be in place to rescue / recover personnel operating from the BMU. This must form part of the operations and maintenance manual / operating instructions.

- All occupants must be familiar with the rescue plan.

For overnight or longer periods, the platform must be parked in its storage position, secured to the structure (where applicable) and the power disconnected.

If at any time the BMU breaks down or a limit switch is activated:

- The operator must inform MPX

- MPX must contact the supplier / installer to rectify the fault and/or reset the limit switch.

- After this type of event only the supplier/installer technicians are permitted to re-inspect and deem the BMU safe for continued operation.

R Inspection and maintenance must be in accordance with the manufactures specifications and:

Legal and Other Requirements

- AS 1418.13: Cranes (including hoists and winches), Building maintenance units

- AS 2550.13: Cranes - Safe Use - Building maintenance units.

- Managing Risks of Plant Code of Practice (Qld) 2013

Document Control

Version 1 August 2019 – New Procedure